Method for preparing coarse-particle aluminum hydroxide from aluminum ammonium sulfate solution

A technology of aluminum ammonium sulfate and aluminum hydroxide, which is applied in the preparation of aluminum hydroxide and other directions, can solve the problem of difficulty in producing coarse-grained aluminum hydroxide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

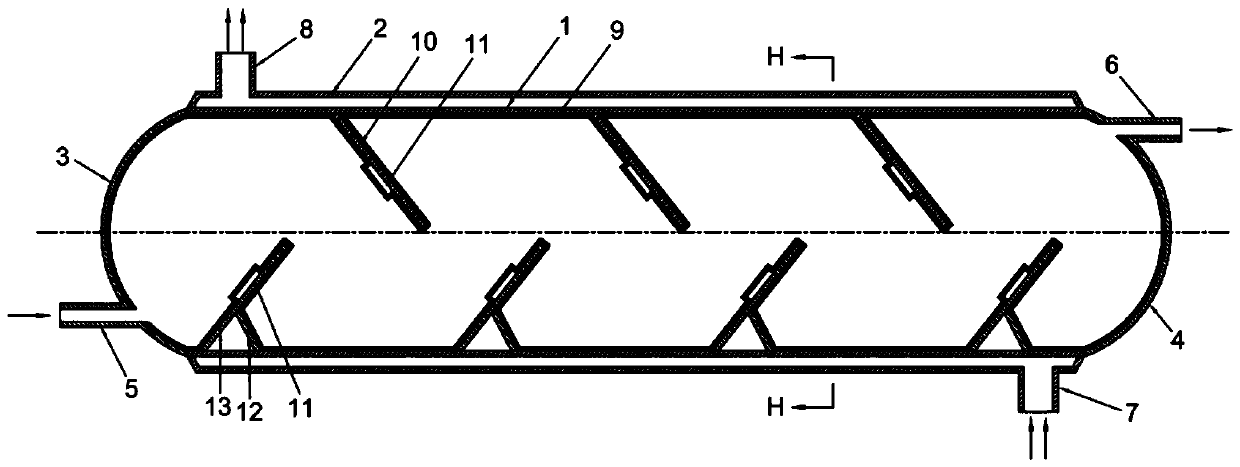

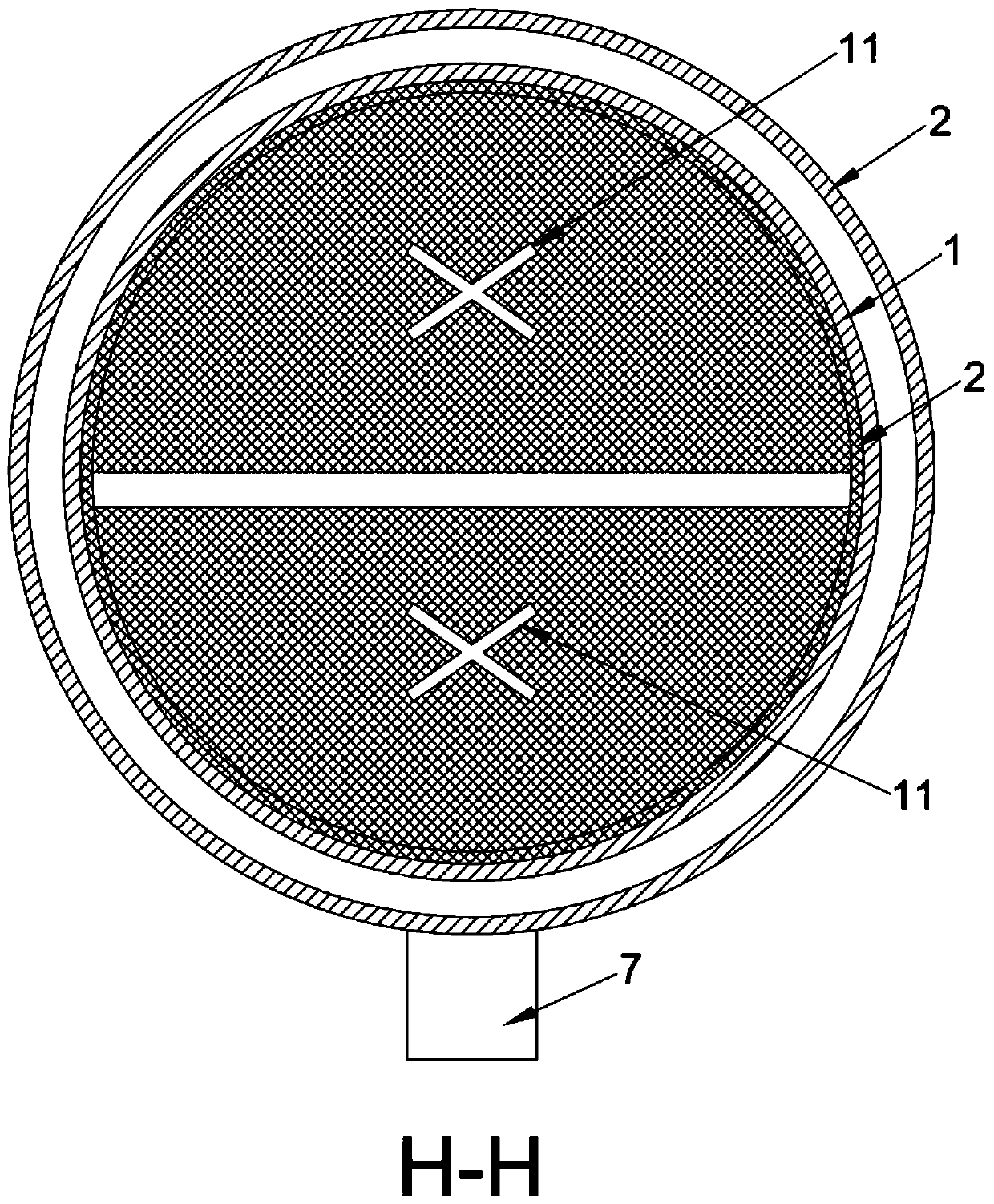

[0035] A method for preparing coarse-grained aluminum hydroxide from an ammonium aluminum sulfate solution. The preparation materials include ammonium aluminum sulfate solution, ammonia water, and a crystal growth accelerator; The feed port 5 of the horizontal reaction tank is pumped into the horizontal reaction tank. The crystal growth accelerator is sodium dodecylsulfonate, and the addition amount of the crystal growth accelerator is 400 ppm. The effect of the crystal growth accelerator is Promote the growth of aluminum hydroxide particles. Inside the tank body 1 of the horizontal reaction tank, from the feed port 5 to the discharge port 6, there are alternately provided with upper reinforcement baffles 10 that completely cover the upper half of the inner cavity and less than half of the inner cavity. The lower reinforced deflector 13 completely covered by the lower part, the deflector 10 and the tank body 1 are welded and fixed, the surface of the upper reinforced deflector...

Embodiment 2

[0038]A method for preparing coarse-grained aluminum hydroxide from an ammonium aluminum sulfate solution. The preparation materials include ammonium aluminum sulfate solution, ammonia water, and a crystal growth accelerator; The feed port 5 of the horizontal reaction tank is pumped into the horizontal reaction tank, the crystal growth accelerator is sodium dodecylbenzenesulfonate, and the addition of the crystal growth accelerator is 600 ppm, and the crystal growth accelerator It can promote the growth of aluminum hydroxide particles. Inside the tank body 1 of the horizontal reaction tank, from the feed port 5 to the discharge port 6, there are alternately provided with upper reinforcement baffles 10 that completely cover the upper half of the inner cavity and less than half of the inner cavity. The lower reinforced deflector 13 completely covered by the lower part, the deflector 10 and the tank body 1 are welded and fixed, the surface of the upper reinforced deflector 10, th...

Embodiment 3

[0040] A method for preparing coarse-grained aluminum hydroxide from an ammonium aluminum sulfate solution. The preparation materials include ammonium aluminum sulfate solution, ammonia water, and a crystal growth accelerator; The feed inlet 5 of the horizontal reaction tank is pumped into the horizontal reaction tank, and the crystal growth accelerator is a kind of sodium dodecylsulfonate and sodium dodecylbenzenesulfonate or a mixture thereof, and the crystal growth accelerator The addition amount of agent is 500 ppm, and the effect of crystal growth accelerator promotes the growth of aluminum hydroxide particle. Inside the tank body 1 of the horizontal reaction tank, from the feed port 5 to the discharge port 6, there are alternately provided with upper reinforced baffles 10 that completely cover the upper half of the inner cavity and fully cover the lower part that is less than half of the inner cavity. The lower reinforced deflector 13 for shielding, the deflector 10 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com