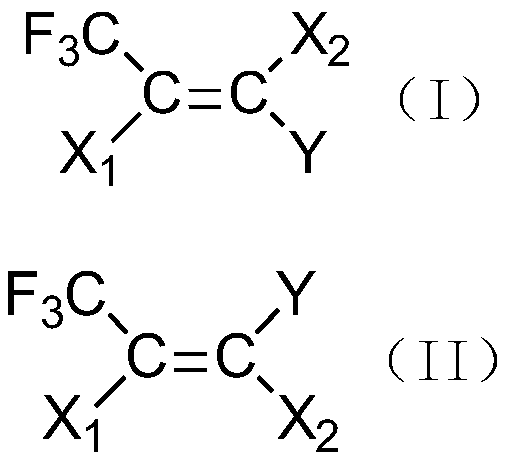

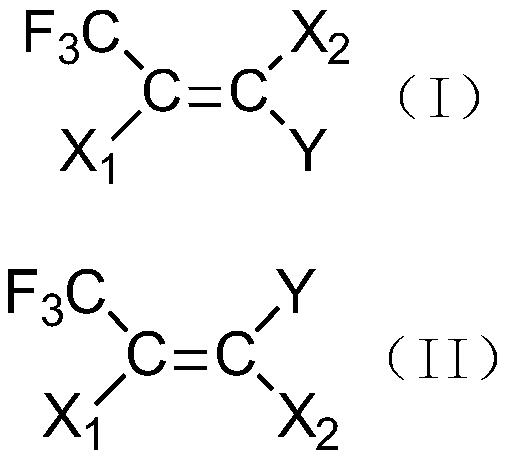

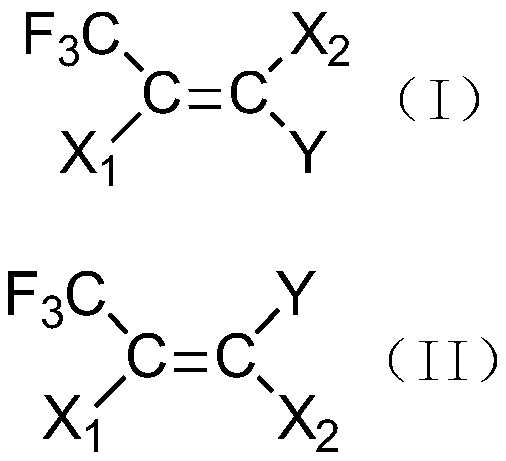

Isomerization process for fluorine-containing olefins

A fluorine-containing olefin, isomerization technology, applied in the field of olefin isomerization, can solve the problems of high reaction temperature, short catalyst activity period, low target product selectivity, etc., and achieve the effect of improving activity and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 280.4g ZrOCl 2 ·8H 2 O and 30.6g Y(NO 3 ) 3 ·6H 2 O were formulated into 1 mol / L solutions respectively, mixed uniformly, and polyethylene glycol was added while stirring, so that the mass percentage of polyethylene glycol in the solution was 10%. Add ammonia solution with a mass fraction of 5% dropwise, adjust the pH value to 8.5, and age the precipitate for 3 hours, then wash with deionized water and suction filter until the AgNO 3 Assay does not detect Cl - . Add isobutanol to the filtered filter cake and stir for 0.5 hours. The volume ratio of filter cake to alcohol solution is 1:3. When the temperature is raised to 120°C, dynamic azeotropic distillation is performed to obtain primary powder. Raise the primary powder to 600°C at a rate of 5°C / min in a nitrogen atmosphere, and calcinate it for 2 hours to obtain Y / ZrO 2 Powder. 9.4g Cu(NO 3 ) 2 ·3H 2 O was made into a solution, and an equal volume of Y / ZrO was impregnated 2 The powder was then dried under ...

Embodiment 2

[0063] The same operation as in Example 1, the difference is that the fluorine-containing olefin isomerization catalyst is made of Zr(NO 3 ) 4 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 3 ·6H 2 O was prepared according to the metal atomic mole percentage Co:La:Zr=15:10:75, and the flow rate of HFO-1234(E) was changed to 25mL / min. The results are shown in Table 1.

Embodiment 3

[0065] The same operation as in Example 1, the difference is that the fluorine-containing olefin isomerization catalyst is made of ZrOCl 2 ·8H 2 O, MgCl 2 、RuCl 3 It was prepared according to the molar percentage of metal atoms Ru:Mg:Zr=0.1:1:98.9, and the flow rate of HFO-1234(E) was changed to 50mL / min. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com