Relaxation device for polyester fabric dyeing

A polyester fabric relaxation technology, which is applied in the field of relaxation devices for polyester fabric dyeing, can solve the problems of poor relaxation effect affecting dyeing quality, and achieve the effect of improving dyeing effect and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

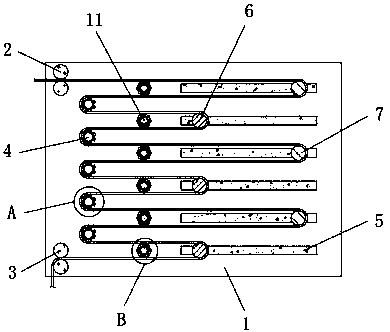

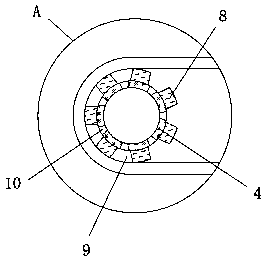

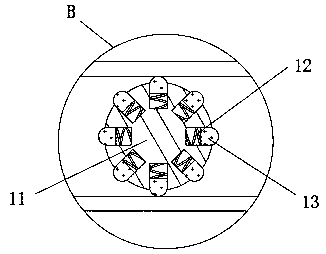

[0028] refer to Figure 1-5 A relaxation device for polyester fabric dyeing, comprising two fixed frames 1, the top between the two fixed frames 1 is rotatably connected with two feed rollers 2, and the bottom between the two fixed frames 1 is rotatably connected with two A discharge roller 3, polyester fabric is connected between the two feed rollers 2 and between the two discharge rollers 3, the feed roller 2 and the discharge roller 3 are located on the same side of the fixed frame 1, and the two fixed frames The side between 1 near the feed roller 2 is rotatably connected with supporting rollers 4 distributed equidistantly in the vertical direction, and the outer walls of the opposite ends of the two fixed frames 1 are fixed on the side far away from the feed roller 2 with equidistant distribution in the vertical direction. electric guide rail 5, and the electric guide rail 5 is set horizontally, the electric guide rail 5 is located between two adjacent supporting rollers ...

Embodiment 2

[0037] refer to Figure 4-6 , a relaxation device for polyester fabric dyeing, the limit rollers 6 between the two fixed frames 1 are equidistantly distributed in the horizontal direction, and the connecting rollers 7 between the two fixed frames 1 are equidistantly distributed in the horizontal direction, The limiting roller 6 and the connecting roller 7 above it are respectively located on both sides of the electric guide rail 5, so that there is a difference in the length of the fabric at the position above and below the limiting roller 6 and the connecting roller 7, and there is a tension or loosening in the dispersed area. difference, so as to increase the rebound strength during the reciprocating tightening and anti-loosening process, so as to enhance the actual relaxation effect on polyester fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com