Glass mirror surface bright gold card paper structure and production method thereof

A production method and glass technology, applied in paper, papermaking, paper coatings, etc., can solve the problems of large environmental pollution, consumption of raw materials and resources, and non-natural degradation of base film, so as to reduce pollution, reduce the amount of base film, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

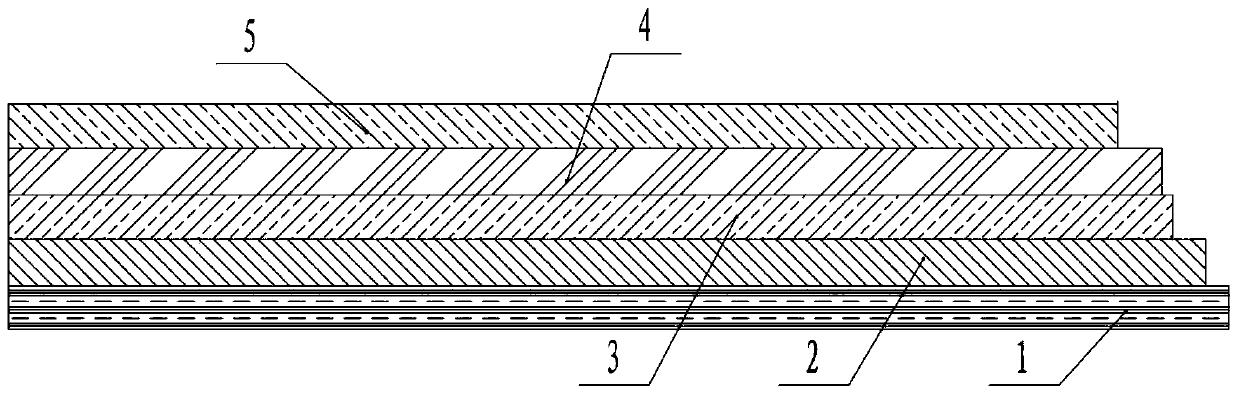

[0031] Embodiment 1: as figure 1 As shown, a glass mirror bright gold cardboard structure, including from bottom to top back coating 1, white card bottom layer 2, metal imitation glass layer 3, varnish color layer 4 and printing finishing layer 5, metal imitation glass layer 3 Use a mixture of water-based high-gloss silver and imitation glass card glue.

[0032] Preferably, the weight ratio of the above-mentioned water-based high brightness silver to the imitation glass card glue is 2:1.

Embodiment 2

[0033] Embodiment 2: A production method of a glass mirror bright gold cardboard structure, the method is: add water-based high-brightness silver to imitation glass card glue, obtain a kind of imitation glass card high-brightness silver glue coating, paint and reel white cardboard Coating and compounding PET base film, drying the reel composite paper, placing it for 36-48 hours to mature, peeling off the PET base film (the peeled PET base film is reused more than 25 times), and obtaining a glass-like bright silver card bottom paper, press The required color is applied to the imitation glass bright silver cardboard to obtain a new packaging material of glass mirror bright gold cardboard with a multi-layer structure.

[0034] A method for producing a glass mirror bright gold cardboard structure, specifically comprising the following steps:

[0035] (1) Fully dissolve and mix the water-based high-brightness silver ink and imitation glass card glue, and disperse evenly;

[0036] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com