Protection structure for high and steep slope and construction method thereof

A technology for protective structures and high and steep slopes, which can be used in basic structure engineering, excavation, construction, etc. It can solve the problems of difficulty in forming effective connections of prefabricated beams, difficulty in transporting concrete on site, and poor concrete tamping effect, etc., to achieve high construction efficiency , easy to implement, good seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

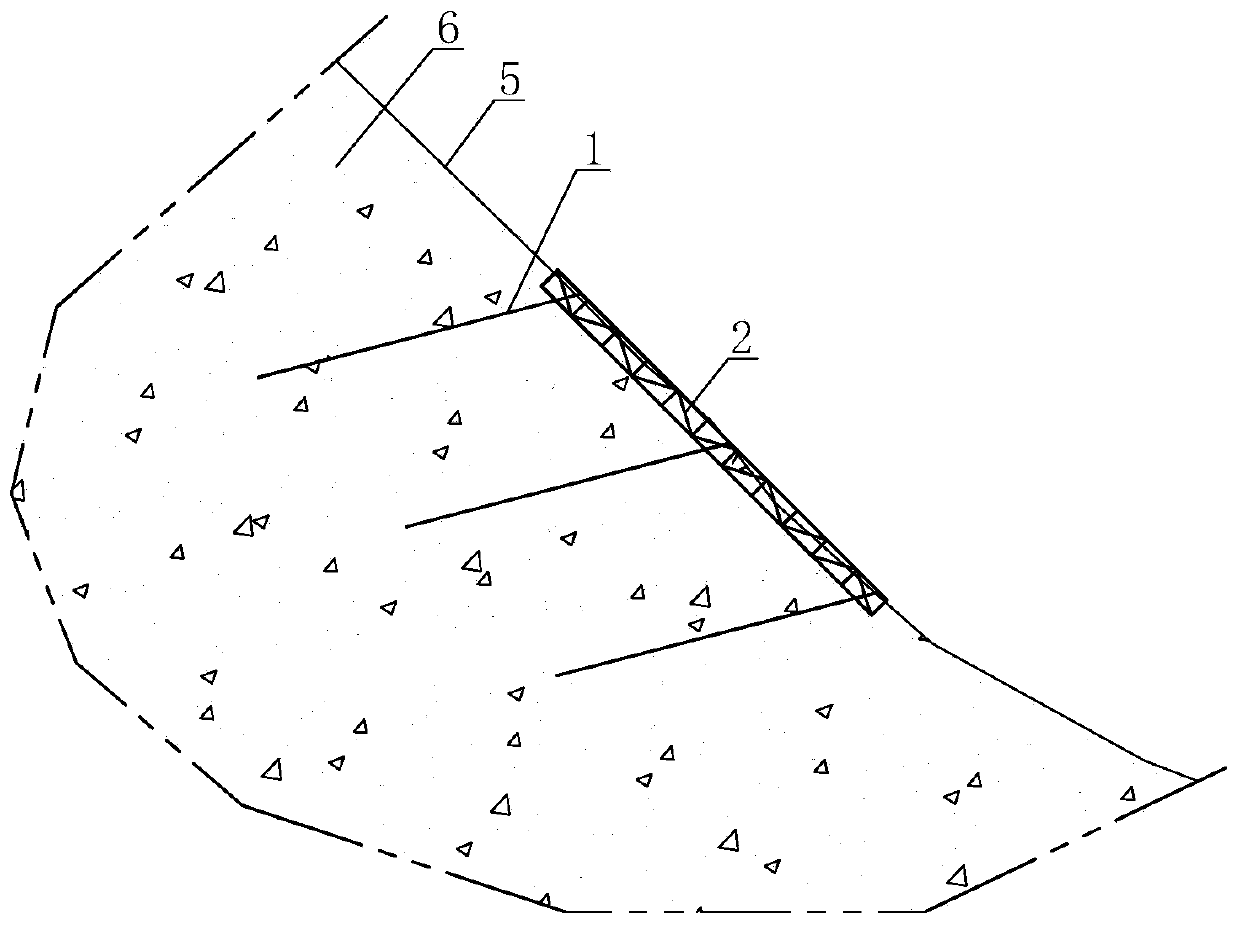

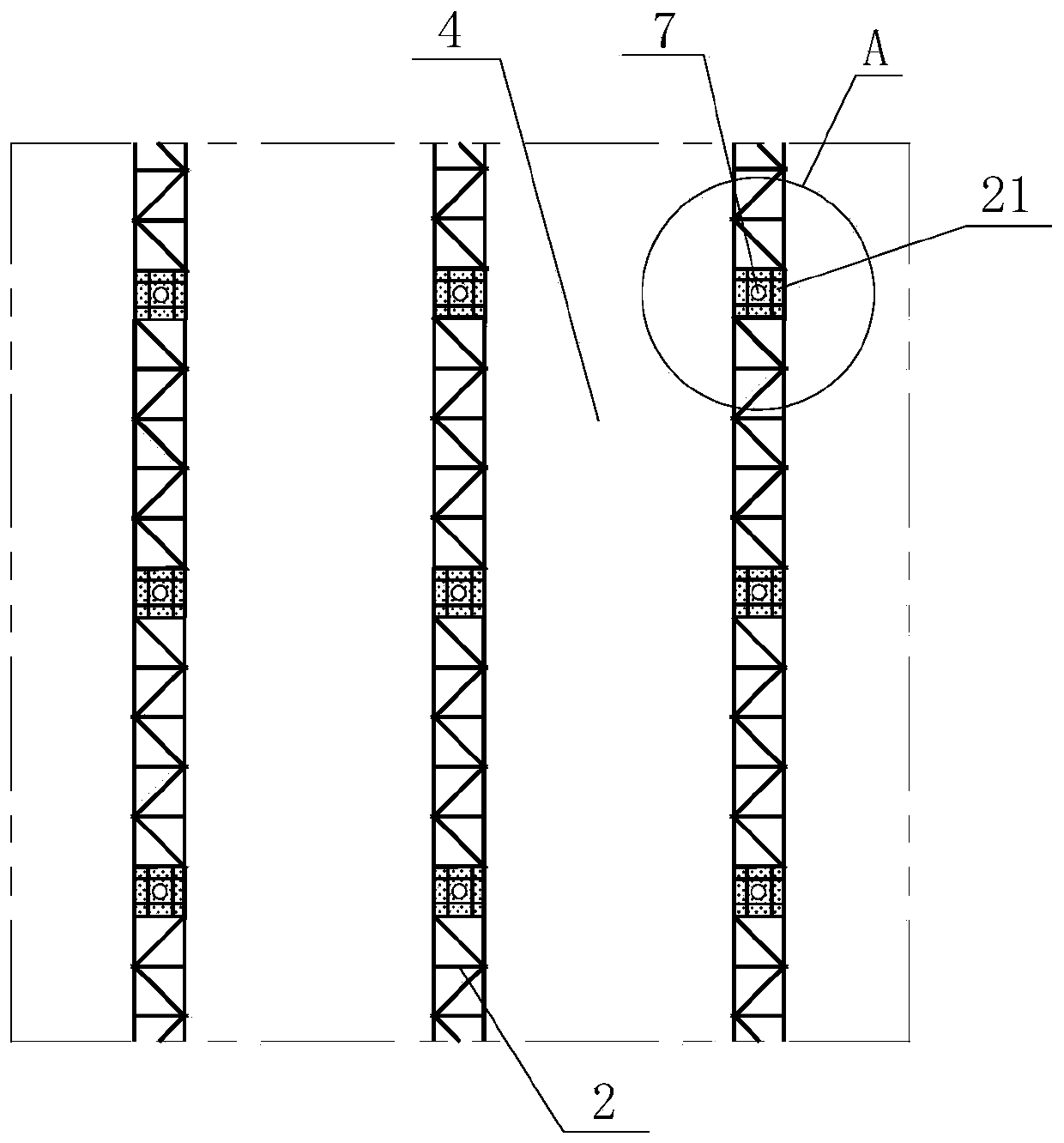

[0061] Such as Figure 1-4 As shown in and 8, a high and steep protective structure for high and steep slopes described in this embodiment includes inclined anchor cables 71 and truss steel beams 2, and truss steel beams are arranged at intervals along the slope surface 5 of the high and steep slope 6 The beam 2; the inclined anchor cable 71 is anchored into the slope body of the slope 6 at equal intervals along the high and steep slope 6; ; Plant slope protection 4 is set in the slope of two adjacent truss steel beams 2 .

[0062] In the above solution: the inclined anchor cable 71 is: at least a part of the anchor cable is anchored on the side slope 6 but not perpendicular to the slope surface 5 .

[0063] The truss steel beams 2 are embedded in the surface of the high and steep slope 6; the truss steel beams 2 are assembled on site, and the truss steel beams 2 are arranged in parallel at equal intervals on the slope 6; After the truss steel beam 2 is installed, the tamped...

Embodiment 2

[0073] Such as Figure 1-4 Shown in and 8, a kind of construction method described in the present embodiment is used to form a kind of high and steep protective structure for the high and steep slope described in embodiment 1, this method comprises the following steps:

[0074] ①. Determine the hole position of the inclined anchor cable 71, drill into the hole with a drilling rig, install and grout the inclined anchor cable 71;

[0075] ②. After the construction of the inclined anchor cable 71 on the slope surface is completed, the position of the truss steel beam 2 is positioned and the groove is cut;

[0076] ③. Assemble the truss steel beam 2 while transporting the rods;

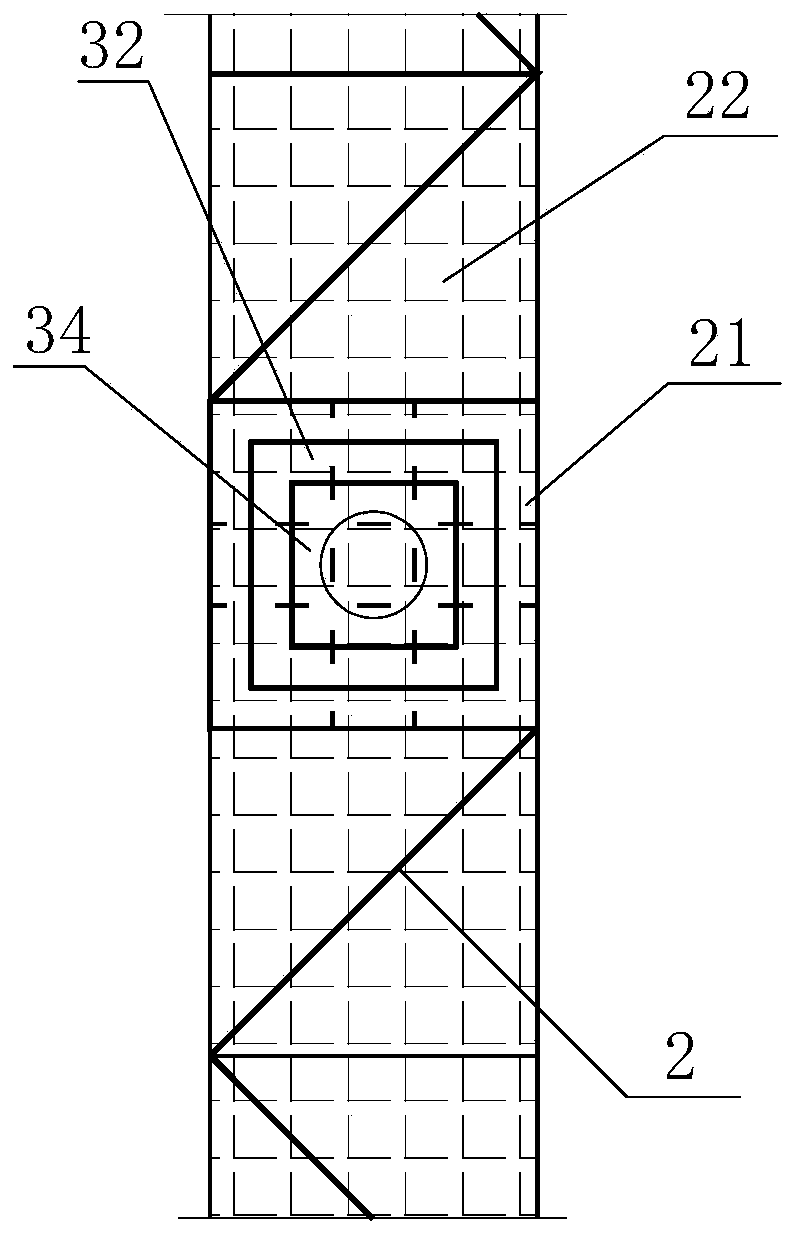

[0077] ④. Pass the inclined anchor cable 71 steel strand through the center of the well-shaped composite member through the wedge-shaped seat 32, and weld and fix the bottom surface of the wedge-shaped seat 32 to the well-shaped composite member;

[0078] ⑤. Put the jack base on the top surface of the w...

Embodiment 3

[0083] Such as figure 1 , 5 , 6, 7 and 8, the protective structure for high and steep slopes described in this embodiment differs from Embodiment 1 or 2 in that it includes a frame truss structure and inclined anchor cables 71, along The truss steel girders 2 and truss beams 33 are arranged at intervals on the slope surface of the high and steep slope 6 to form a frame truss structure; inclined anchor cables 71 are obliquely anchored into the slope body of the slope 6; wedge-shaped seat 32, anchorage 31, and bucket-shaped steel plate head 34 are sequentially arranged on the intersection joints of the truss steel beam 2 and the truss beam 33;

[0084] In the above scenario:

[0085]The truss steel beam 2 and the truss beam 33 are embedded in the surface of the high and steep slope 6; The lattice layout is square or rhombus; after the truss steel beam 2 and truss beam 33 are installed, the gaps are backfilled with excavated soil; in the slope 6 in a corrosive environment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com