Large crawler type integrated horizontal directional drilling rig

A horizontal directional drilling rig and crawler type technology, applied in the field of large-scale crawler-type integrated horizontal directional drilling rig and trenchless equipment, can solve the problems of integrated installation, can only be separated separately, increased cost, inconvenient transportation, etc., to reduce hydraulic oil pipelines The effect of connecting, preventing hydraulic oil leakage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical solutions adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

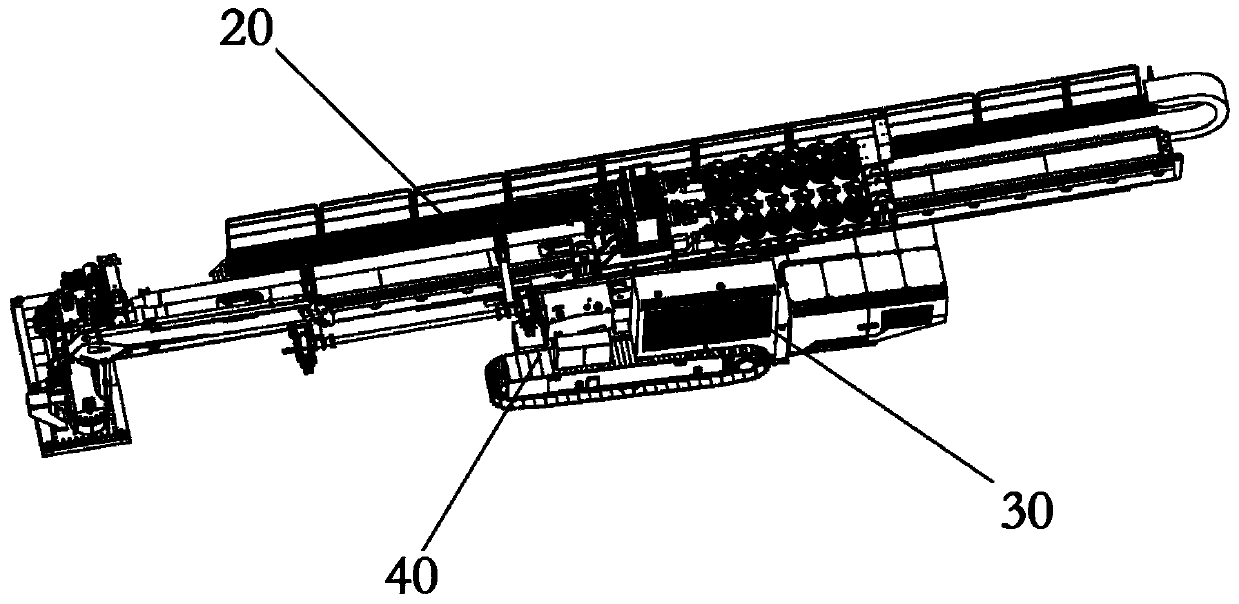

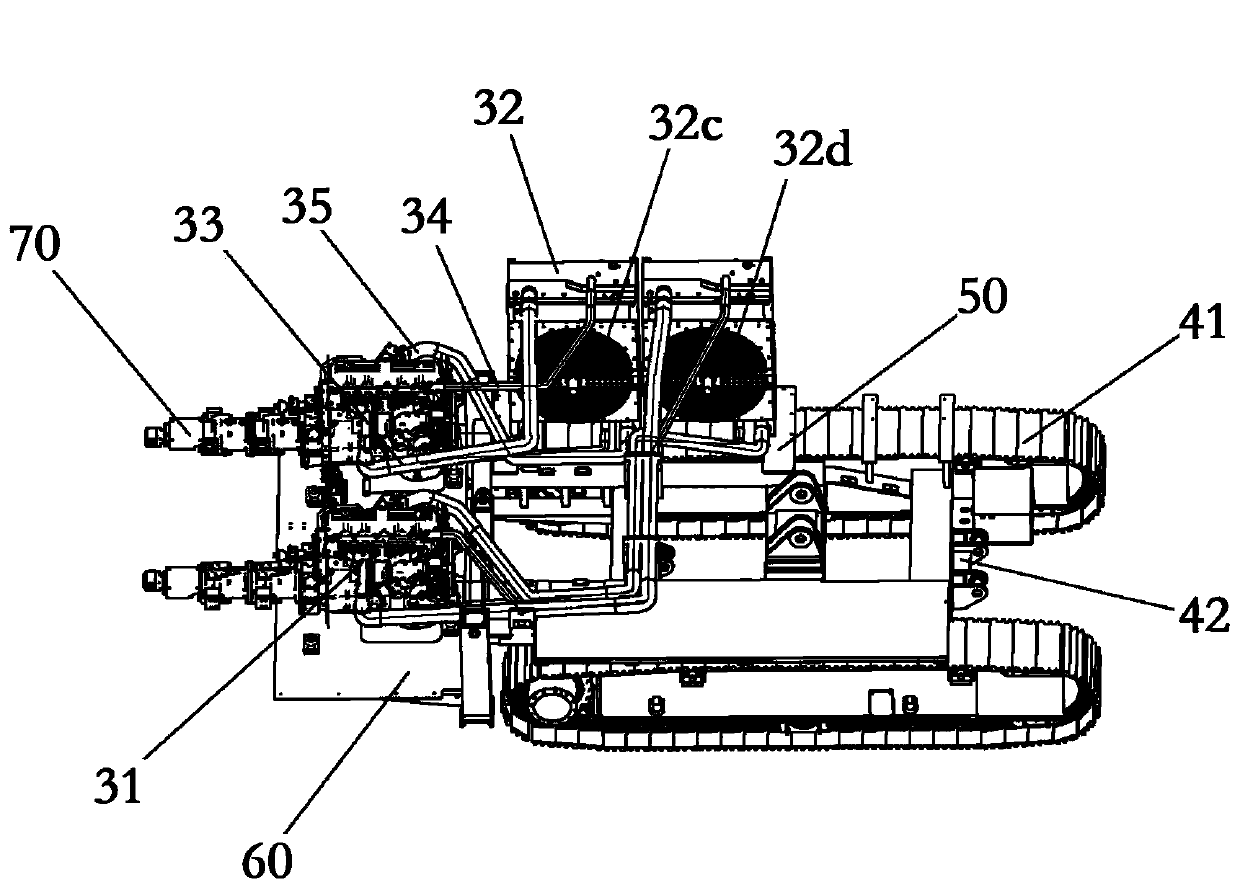

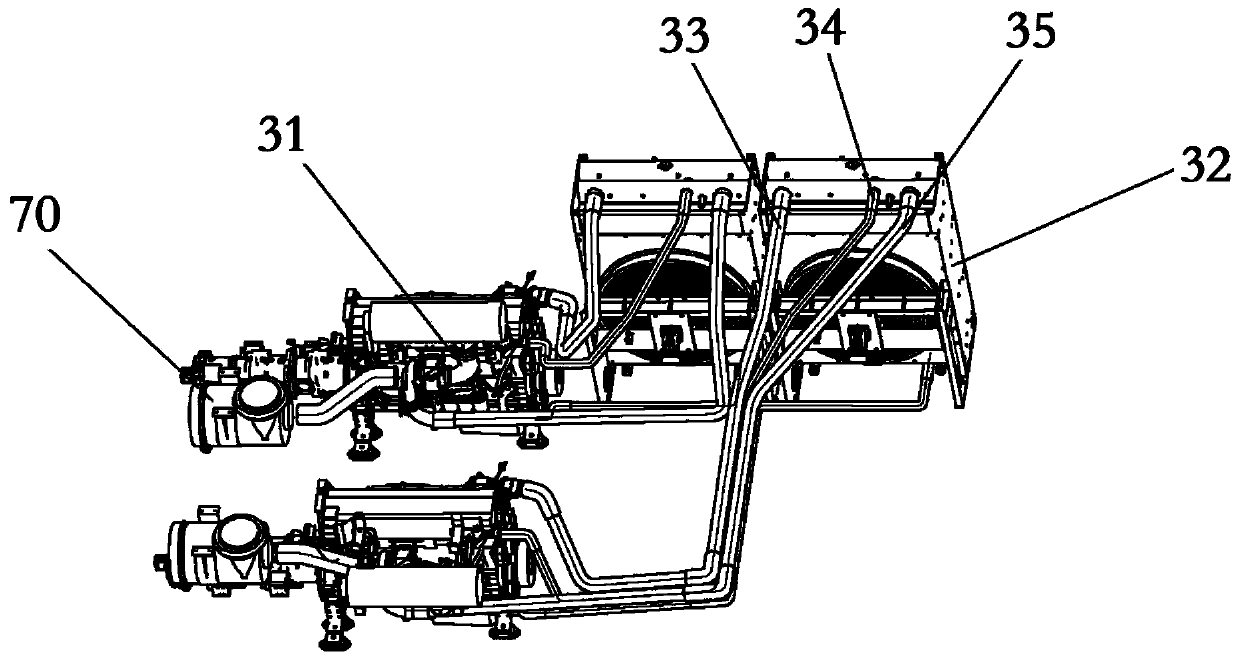

[0027] refer to Figure 1 to Figure 3 , the present invention provides a large crawler-type integrated horizontal directional drilling machine, which includes a main machine part 20 , a power part 30 , a running part 40 , a first connecting frame 50 and a second connecting frame 60 . The main unit 20 includes the main body of the drilling rig, the power unit 30 includes two engines 31 and two cooling water tanks 32, the running unit 40 includes symmetrically arranged track wheels 41 and a track beam frame 42 connected to the track wheels 41, and the main unit 20 is fixed on the track beam Rack 42. Both the first connecting frame 50 and the second connecting frame 60 are connected and fixed to the track beam frame 42, the first connecting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com