Petrochemical multi-dimensional perception inspection robot and power supply system thereof

An inspection robot, petrochemical technology, applied in control/regulation systems, instruments, motor vehicles, etc., can solve the problems of insufficient heat dissipation, inconvenient troubleshooting, large power and loss, etc., to avoid mutual interference and power supply. The effect of pollution and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

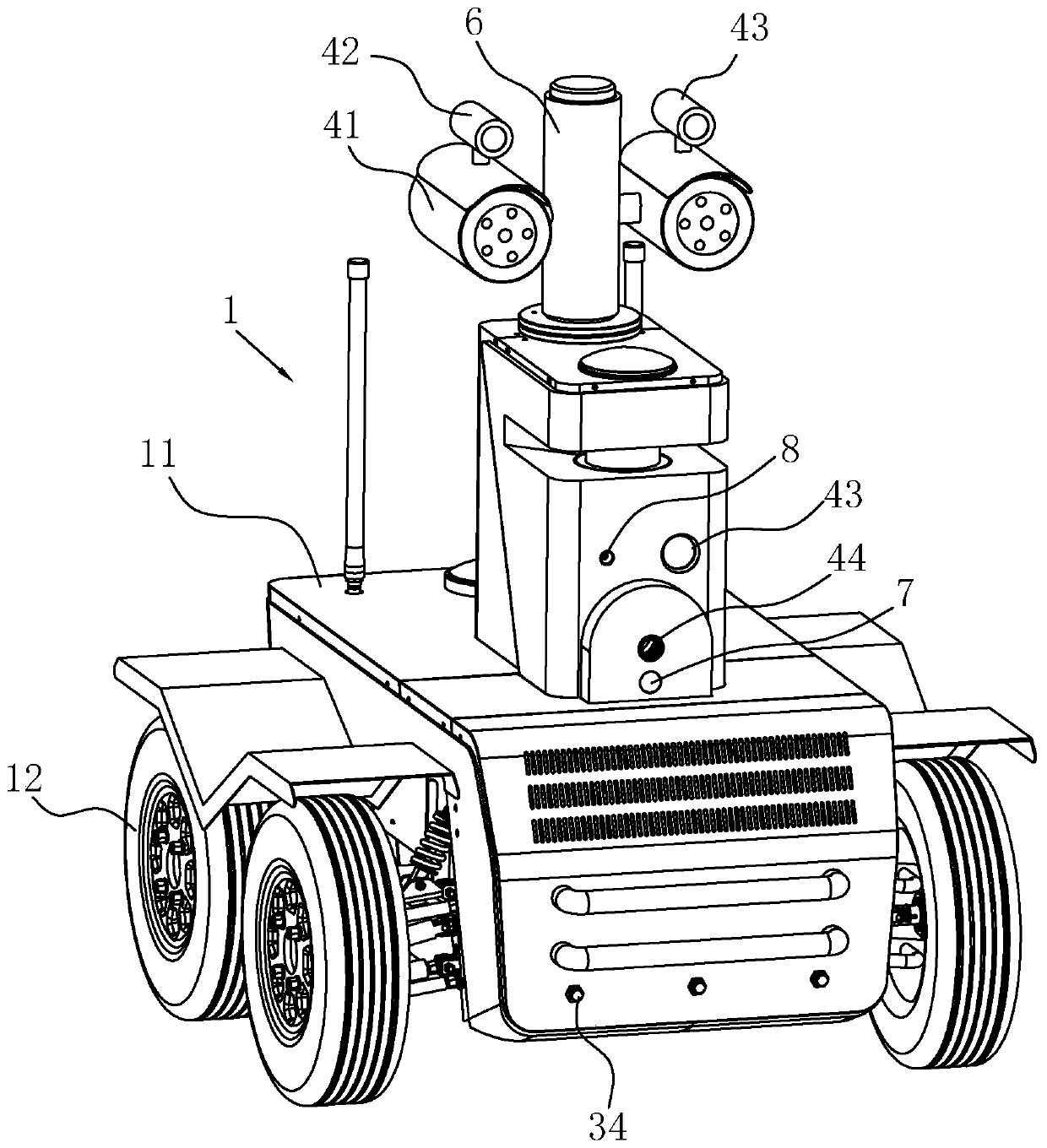

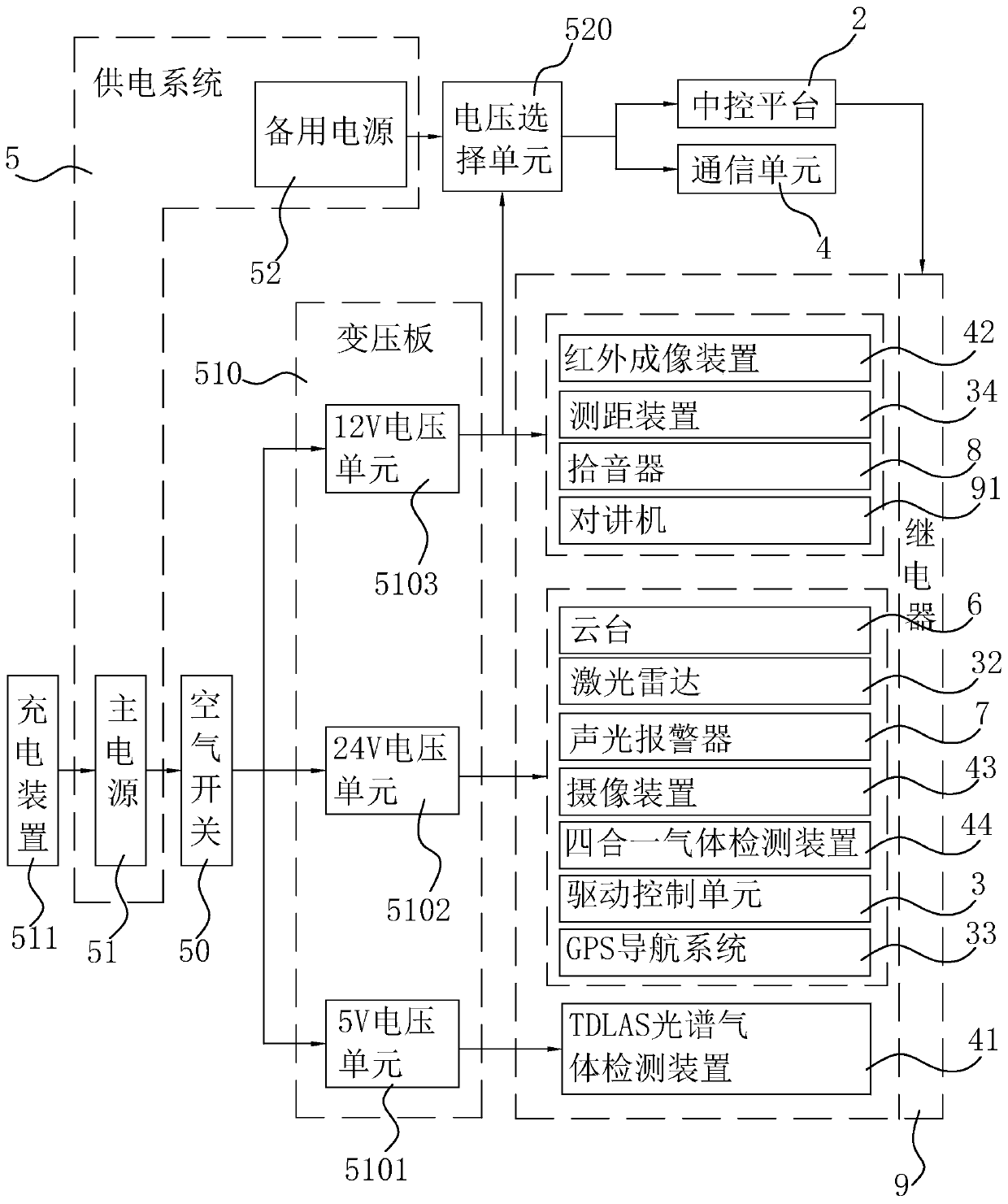

[0034] The invention discloses a petrochemical multi-dimensional perception inspection robot, such as figure 1 Shown, comprise explosion-proof car body 1, explosion-proof car body 1 comprises explosion-proof carriage 11 and the wheel 12 that is positioned at the bottom of explosion-proof carriage 11; Explosion-proof carriage 11 is provided with hollow cavity, as figure 1 and figure 2As shown, the central control cavity is installed with a driving control unit 3 for driving the inspection robot to walk, a communication unit 4 for establishing a communication connection between the inspection robot and the remote control center, and a central control platform 2 for realizing navigation and data fusion processing. Both the unit 3 and the communication unit 4 are connected to the central control platform 2; the detection element is installed on the explosion-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com