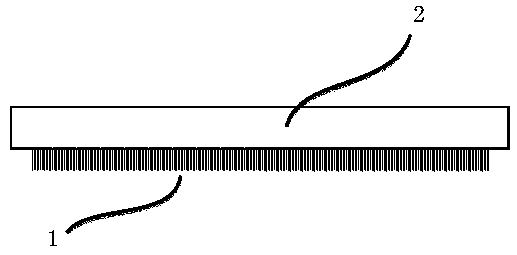

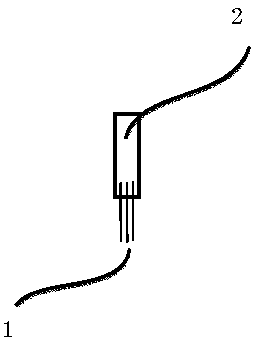

Conductive hairbrush charge injection device and method and application

A technology of charge injection and brush, applied in the direction of electrode structure, electrostatic separation, etc., can solve problems such as difficult to find, short circuit of high-voltage power supply, damage to high-voltage power supply, etc., and achieve the effect of less ozone, power reduction and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Connect the conductor to a high-voltage power source and discharge the insulating material, including the solution-sprayed cloth, through the brush.

[0030] Due to the bottom of the initial corona voltage of the conductive hair brush of the present invention, at the same voltage, under the same distance condition, compared with the method of connecting a row of pins or a wire to a high-voltage power supply, more charges can be emitted, and more A lot of charge is injected into the melt-sprayed cloth, and because of the rapid increase of its current, the voltage will be low, so it is not easy to cause ignition. Even if ignition occurs, only a small number of fibers will cause ignition. Due to the certain resistance of the fibers, the ignition is reduced. Fire current, so there will be no severe burnout of the solution-sprayed cloth. Thus, the efficiency of the electret is improved.

Embodiment 2

[0032] Connect the conductor to a high-voltage power supply, and charge the particles in the air through brush discharge. Under the same voltage and the same distance, the more particles are charged, the better the effect of adsorption and dust removal, and the power consumption is also reduced. Increased efficiency.

Embodiment 3

[0034] The conductor is connected to the high-voltage power supply, and the paper is charged through the brush, so that the paper is electrostatically adsorbed on the metal plate, preventing the metal plate from being scratched or scratched during the production process, and improving product quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com