Movable building rubbish regenerating treatment system

A technology of construction waste and treatment system, which is applied in grain treatment, construction waste recycling, and the use of liquid separation agents, etc. It can solve problems such as pollution, easy dust, and large pieces of garbage falling into it, so that it is not easy to loosen and the bonding effect is firm. , the effect of not easy to raise dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

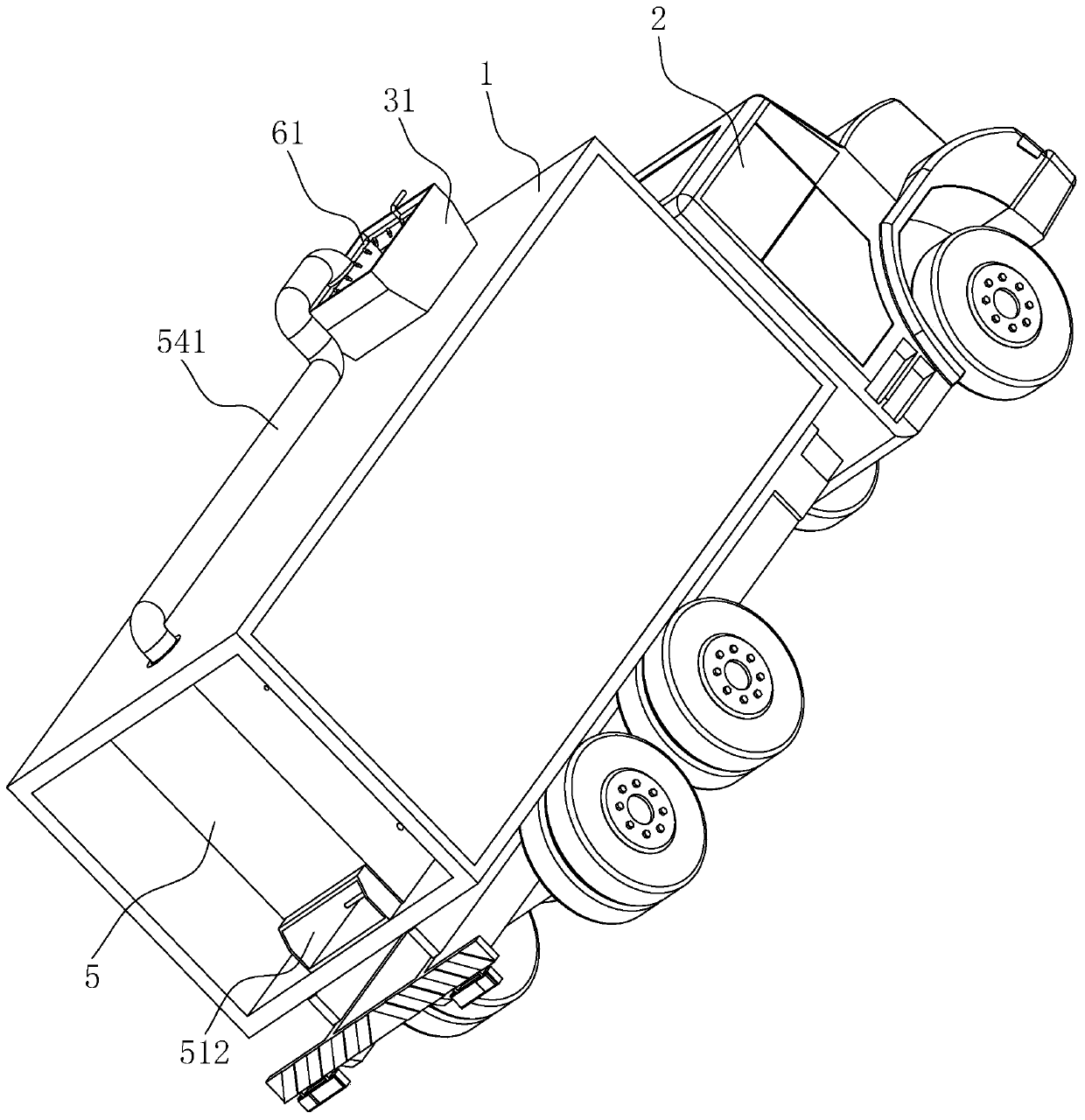

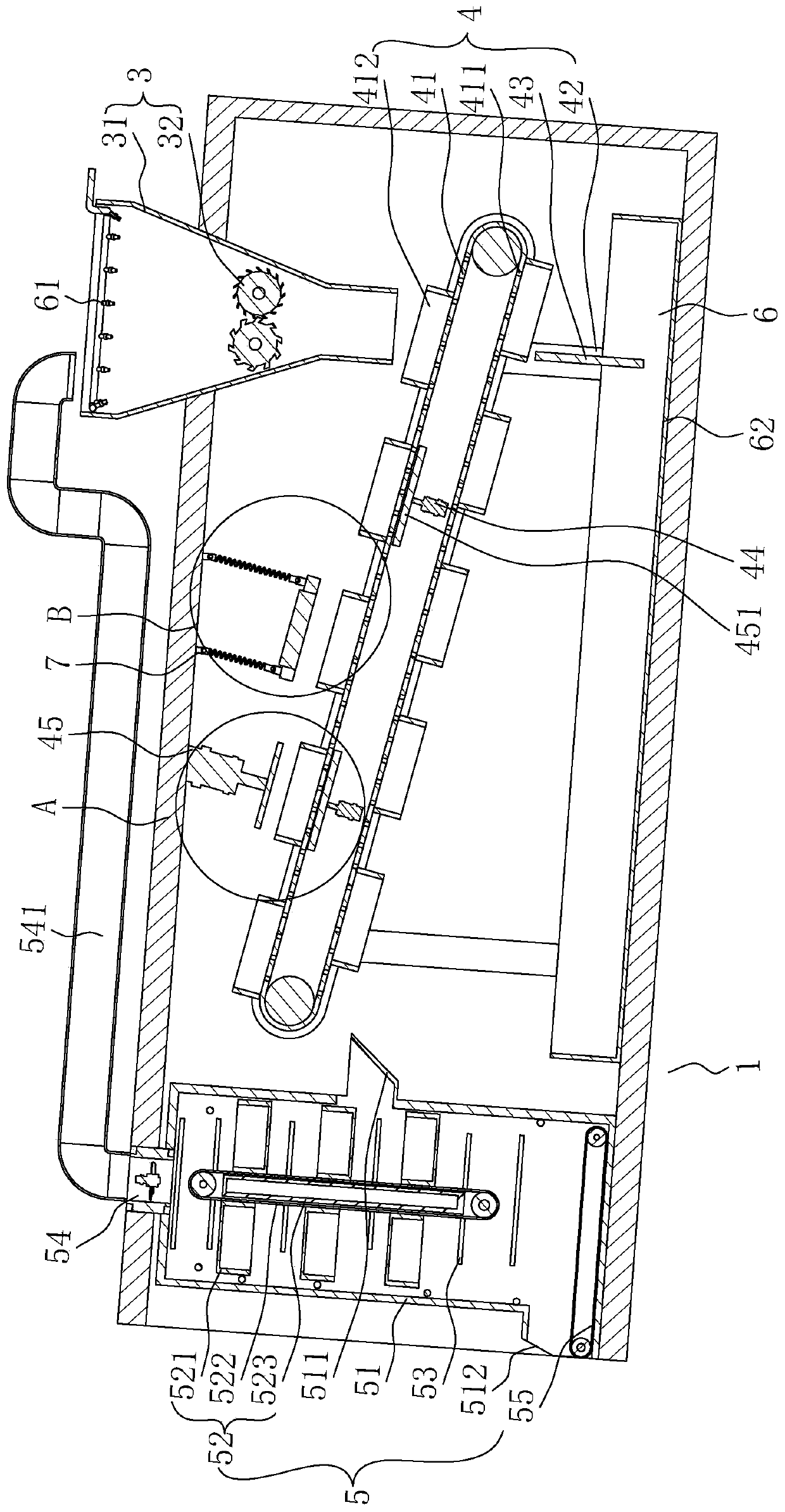

[0043] refer to figure 1 , is a mobile construction waste regeneration treatment system disclosed in the present invention, comprising a container 1 installed on a truck 2 .

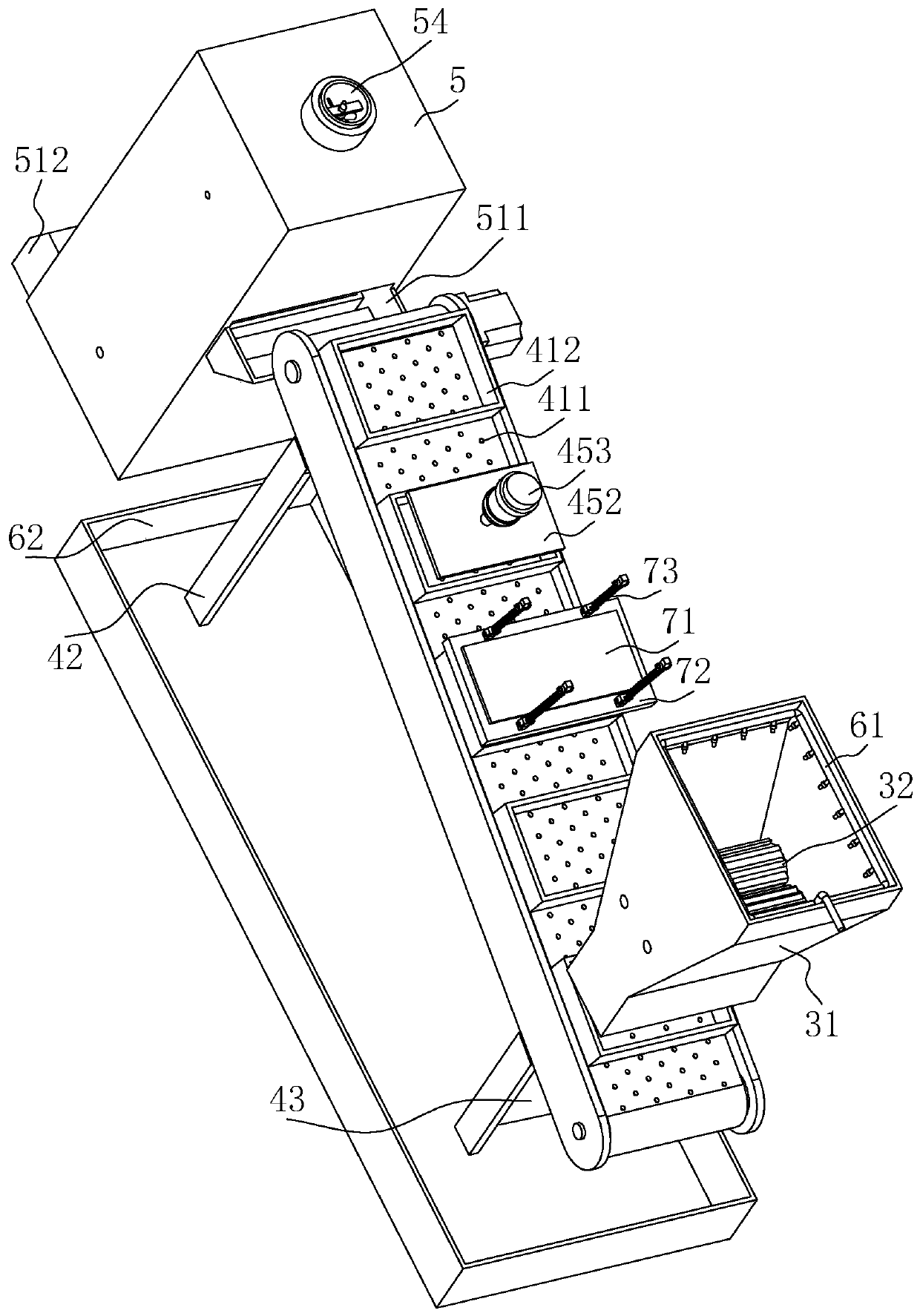

[0044] refer to figure 2 , The container 1 is provided with a crushing device 3 , a forming device 4 , a compacting device 45 and a drying device 5 . Besides, flushing device 6 and metal separating device 7 are also included.

[0045] refer to figure 2 , image 3 , the above-mentioned crushing device 3 is used to crush concrete blocks to form recycled aggregates, and the detailed description of the crushing device 3 is as follows. The crushing device 3 includes a feed hopper 31, and the top of the container 1 is provided with an installation opening, and the feed hopper 31 is installed on the installation opening. Specifically, the feed hopper 31 and the container 1 can be fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com