Subpackaging assembly line for material distribution

An assembly line and sub-packaging technology, applied in the directions of transportation and packaging, conveyors, grinding machine parts, etc., can solve the problems affecting the ornamental quality of finished materials, side leakage of materials, impact deformation, etc., and achieve continuous and accurate protection. Processing effect, guaranteeing integrity and tightness, improving the effect of frame protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

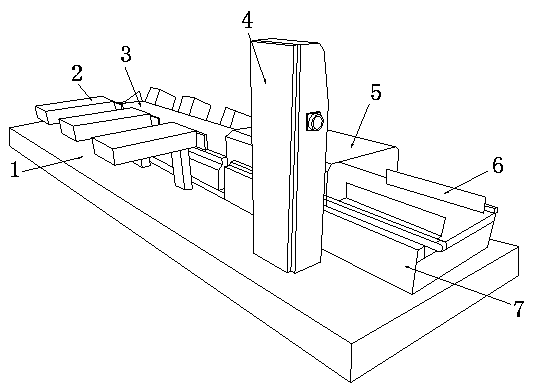

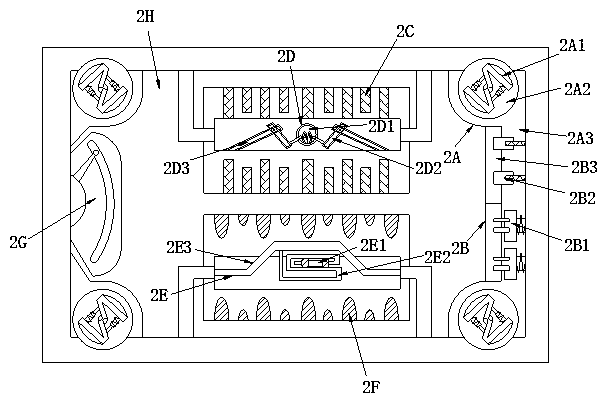

[0033] see Figure 1-Figure 6 , the present invention provides a sorting and packing line for splitting, its structure includes: a base plate 1, a splitting and packing roller groove 2, a conveyor belt 3, a power distribution cabinet 4, a glass shell cover 5, a material blocking plate 6, and a transmission case Seat 7, the said distributing and packing roller groove 2 is provided with three and is all nested in the left side of conveyer belt 3, and described base plate 1 is close to the bottom surface of transmission case seat 7, and described transmission case seat 7 and The power distribution cabinet 4 is electrically connected, the glass cover 5 is nested on the top of the transmission case base 7, the transmission case base 7 is mechanically connected with the conveyor belt 3 and is on the same level, and the material blocking plate 6 is installed on the conveyor belt 3. On the top of the front end, the power distribution cabinet 4 is inserted and embedded on the top surfa...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a kind of sub-packaging line for material distribution, other aspects are the same as embodiment 1, the difference is:

[0041] see figure 2 , the slider deflection frame 2E is composed of a counterweight slider 2E1, a winding crank rod 2E2, and a trapezoidal suspension rod 2E3. The counterweight slider 2E1 is mechanically connected with the winding crank rod 2E2, and the winding pressure crank rod 2E2 Inserted under the bottom of the trapezoidal suspender 2E3 and on the same vertical plane, through the lateral displacement of the counterweight slider 2E1 around the crank rod 2E2, it presses heavily on the plate frame parts, so that the film on the edge of the plate is divided into effect It has been improved, and the degree of maintenance of the sub-materials has been improved.

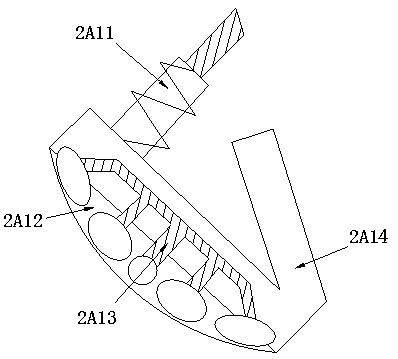

[0042] see Figure 6 The counterweight slider 2E1 is composed of a cross torsion brace 2E11, a horizontal cylinder groove 2E12, a wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com