Hydraulic heat dissipation controlling system, method, device and equipment and engineering machine

A control system and hydraulic technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of time-consuming and oil-consuming, low heat dissipation efficiency of hydraulic system, affecting the working efficiency of construction machinery, etc. Improve heat dissipation efficiency and ensure the effect of working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

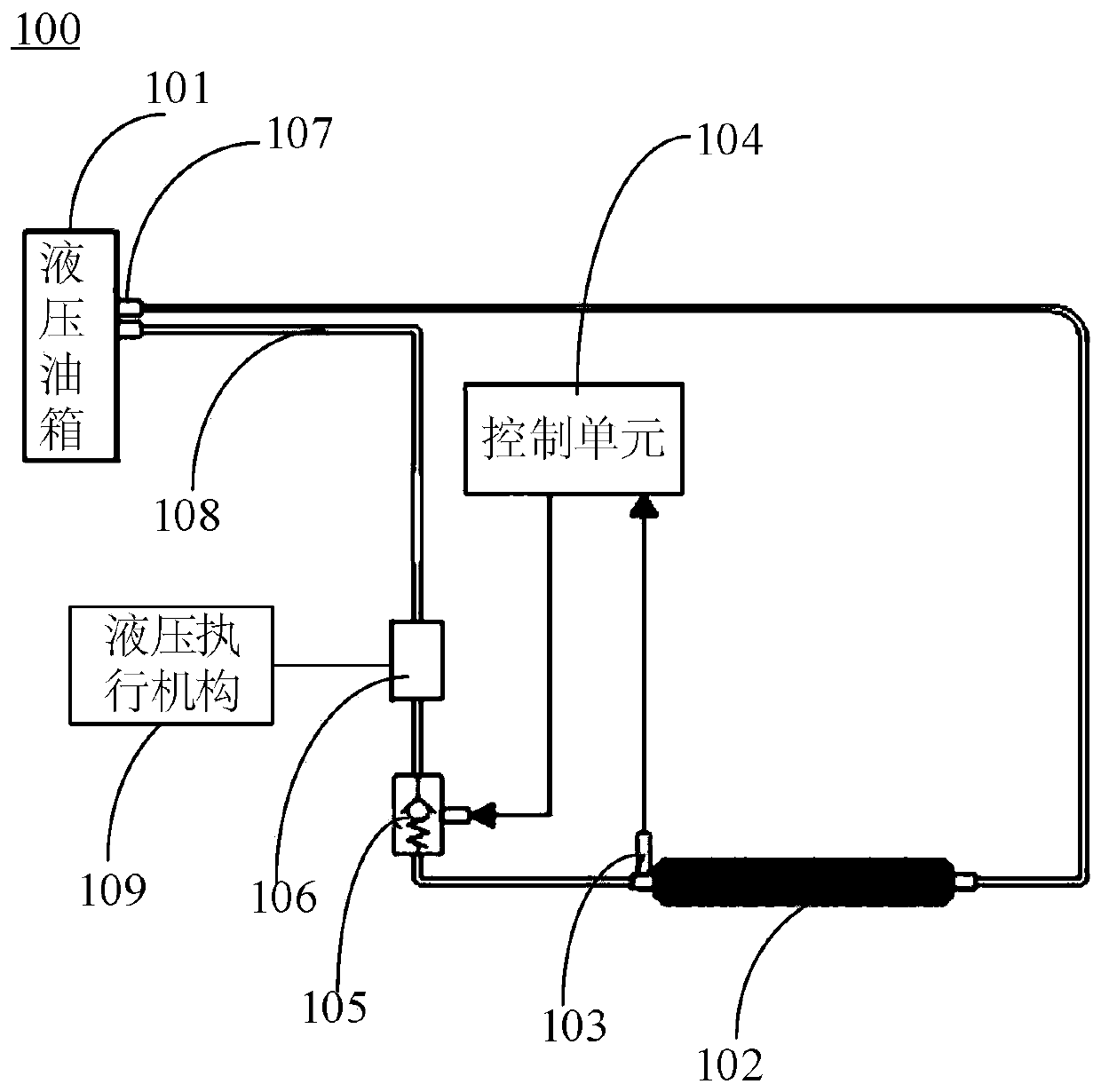

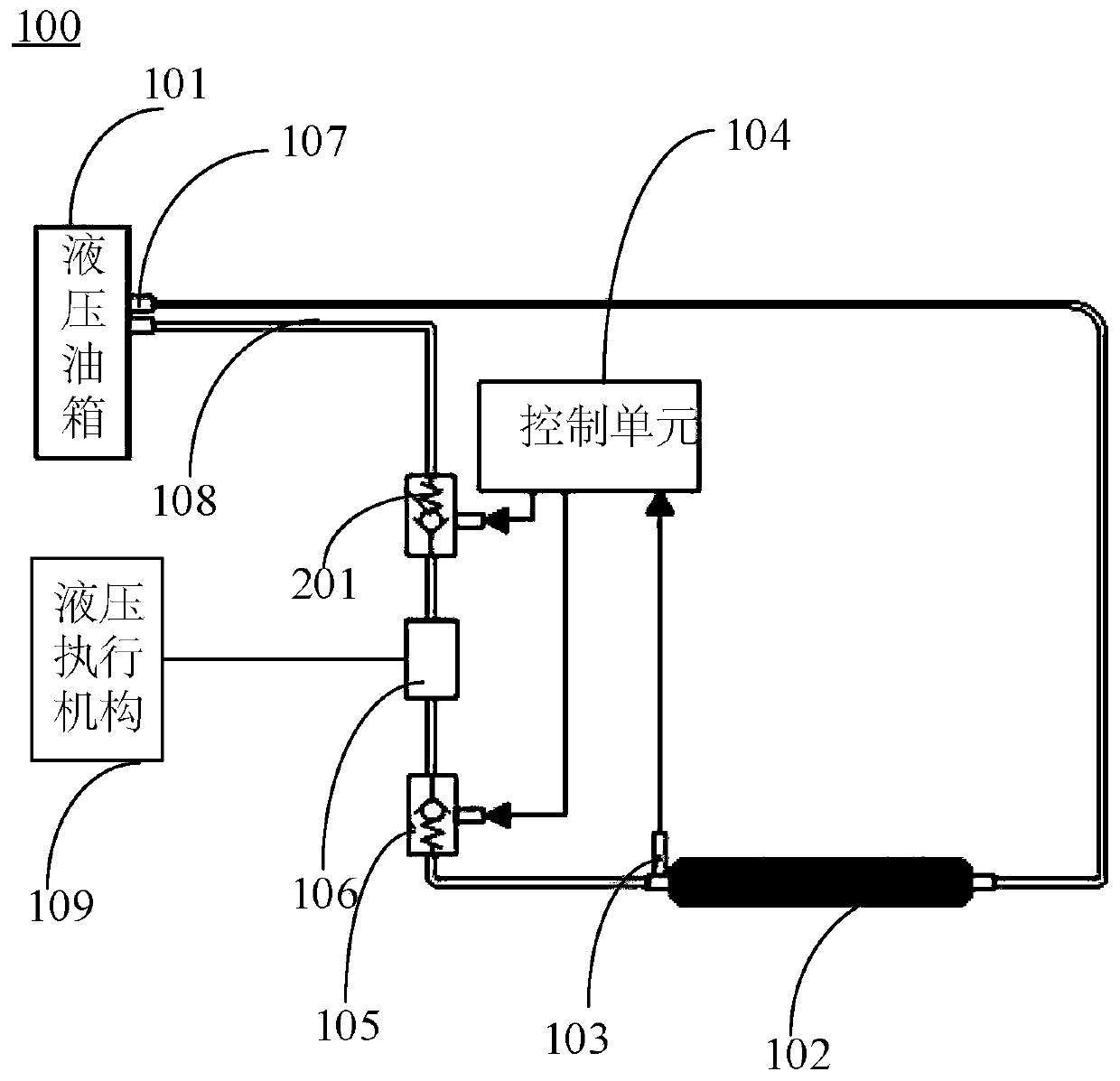

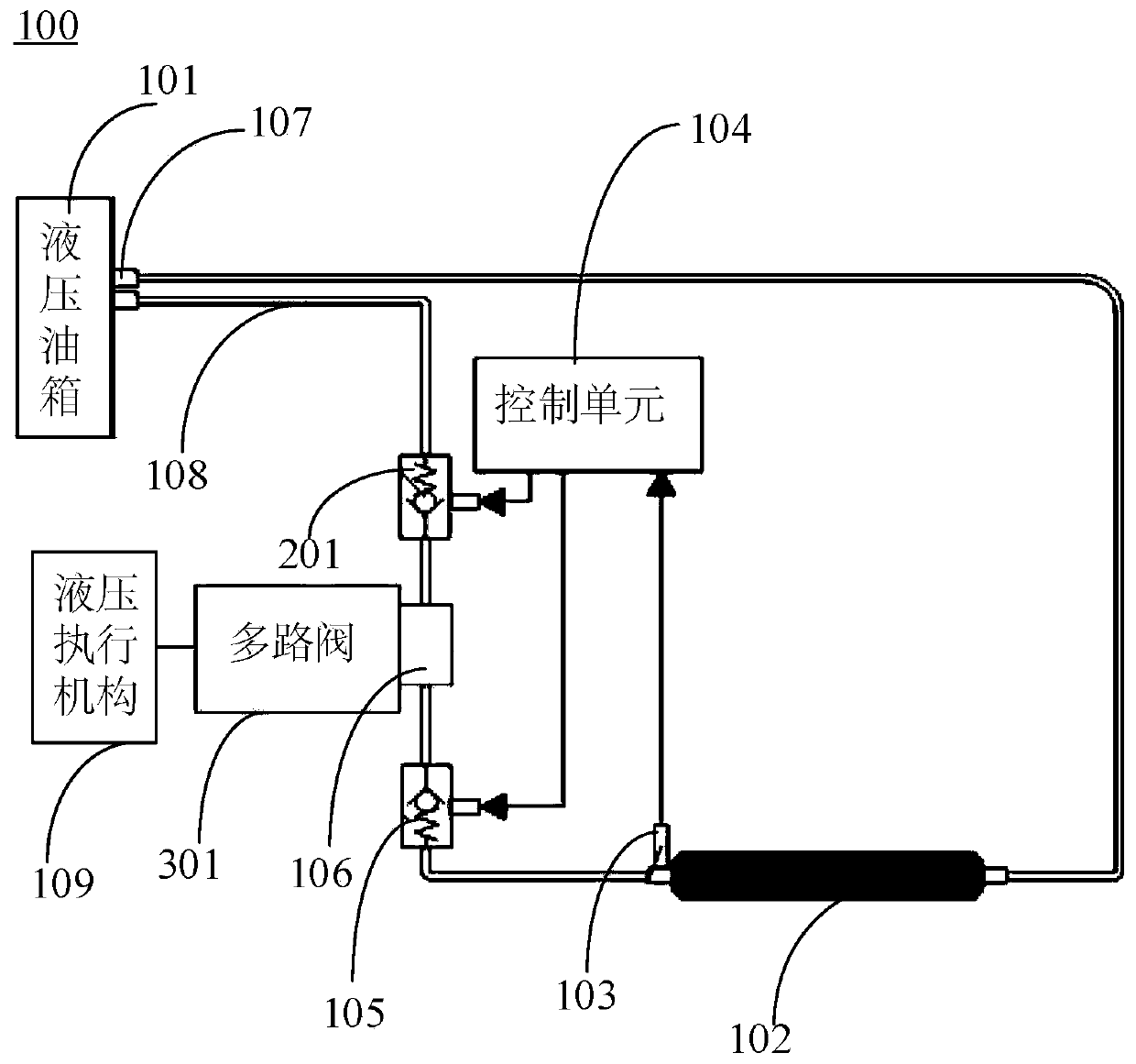

[0046] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

[0047] Construction machinery is a machine that integrates heat source and heat dissipation source. If its heat balance exceeds or fails to reach the heat balance temperature range (ie, overheating or undercooling), it will have an adverse effect on the reliability, environmental protection and efficiency of construction machinery operation.

[0048] For example, the optimal heat balance parameters of construction machinery are as follows: diesel engine water temperature 75°C-95°C, hydraulic oil temperature 55°C-75°C, torque converter oil temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com