Device and method for detecting breakage of prestressed steel wire of prestressed concrete cylinder pipe (PCCP) based on piezoelectric sensing technology

A technology of prestressed steel wire and prestressed steel, applied in the direction of measuring devices, mechanical devices, and material analysis through electromagnetic means, to achieve low cost, high accuracy, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

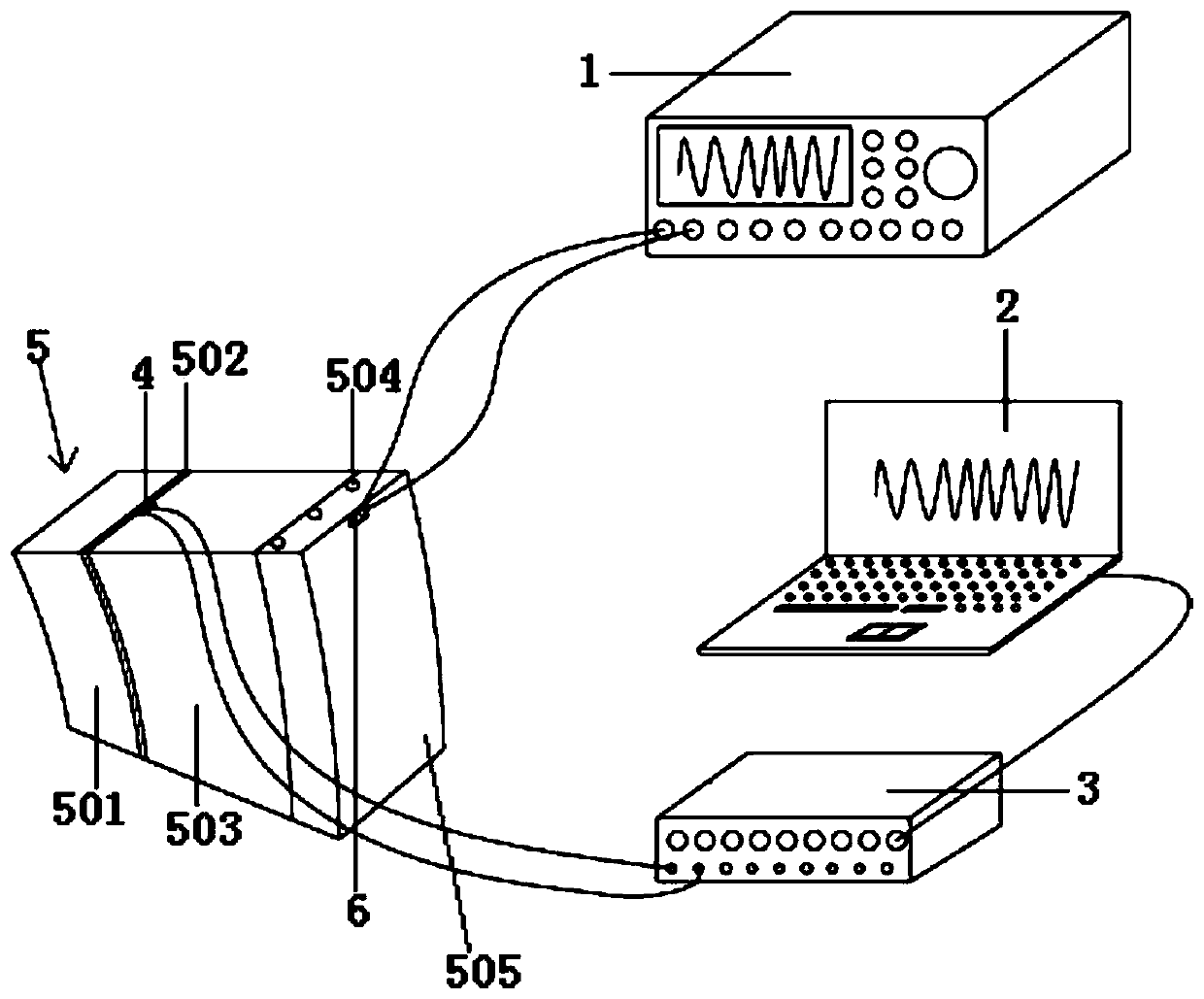

[0033] This embodiment discloses a device for detecting prestressed steel wire fracture in prestressed steel cylinder concrete pipe (PCCP) based on piezoelectric sensing technology, including a waveform generator 1, a data analysis system 2, a dynamic data acquisition system 3, a zirconium titanium Lead acid piezoelectric ceramic sheet I4 and lead zirconate titanate piezoelectric ceramic sheet II6. The data analysis system 2 is a notebook workstation.

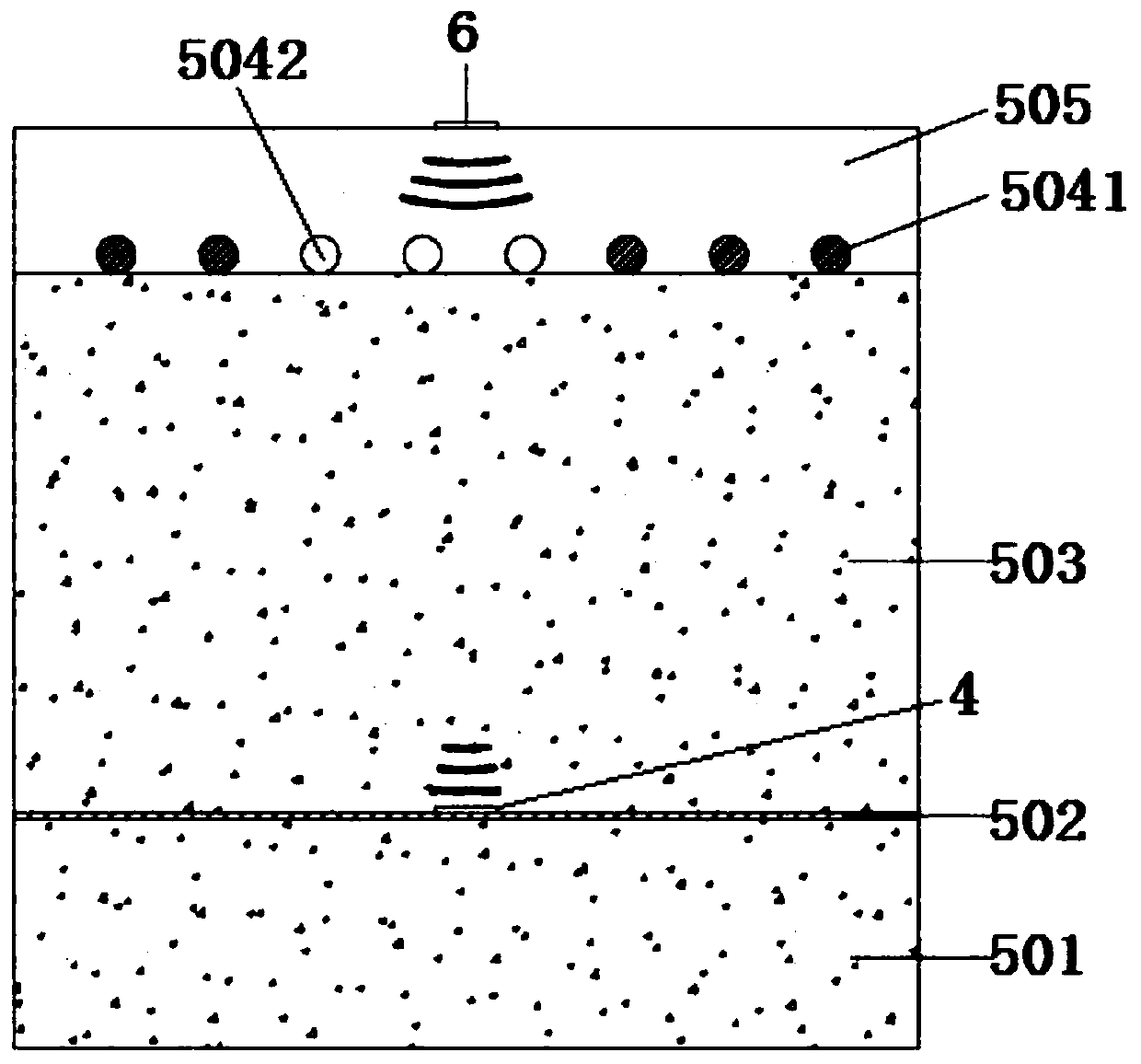

[0034] see figure 1 Or 2, a plurality of said lead zirconate titanate piezoelectric ceramic sheets 4 are arranged on the inside and surface of the PCCP detection section 5, the PCCP detection section 5 is a pipe section with both ends open and the interior is hollow, and the PCCP detection section 5 includes an inner die Concrete 501, outer core concrete 503 and mortar protection layer 505, the inner core concrete 501 is the innermost layer of the pipe wall, the outer surface of the inner core concrete 501 is covered with a st...

Embodiment 2

[0041] This embodiment discloses a method for detecting prestressed steel cylinder concrete pipe (PCCP) prestressed steel wire fracture based on piezoelectric sensing technology, based on the device described in claim 1, comprising the following steps:

[0042] 1) Pouring the inner pipe core concrete 501 of the two PCCP detection sections 5, and setting a steel cylinder 502 on the surface of each inner pipe core concrete 501.

[0043] 2) Paste a number of lead zirconate titanate piezoelectric ceramic sheets I4 on the outer surface of each steel cylinder 502, and the positive and negative terminals of the lead zirconate titanate piezoelectric ceramic sheets I4 have a reserved length.

[0044] 3) Pour outer pipe core concrete 503 on the outer surfaces of the two steel cylinders 502 .

[0045] 4) Wrap several continuous prestressed steel wires 5041 on the outer surface of one outer tubular concrete 503 , and wrap several broken prestressed steel wires 5042 on the outer surface of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap