Cigarette raw material mixing uniformity evaluation method based on design value

A technology of mixing uniformity and evaluation method, which is applied in the field of cigarette processing, can solve the problems of high uniformity measurement results, various detection indicators, and high equipment requirements, and achieves avoiding the improvement of uniformity, simple equipment and operation, and small sample volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

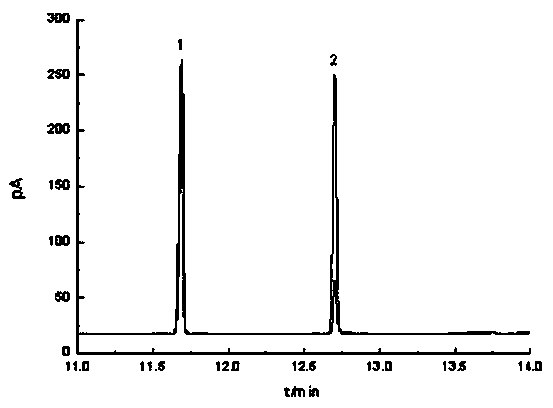

Image

Examples

Embodiment 1

[0030] A method for evaluating the mixing uniformity of cigarette raw materials based on design values, comprising the following steps:

[0031] (1) Sampling and pretreatment of samples: select cigarettes with a design value of 20% mixed ratio of cut stems of a certain specification, and take samples during the production and processing time of a batch, during the packaging process, and take samples every 1 hour, a total of 10 times, each Take 5 cigarettes at a time; the cigarettes you take correspond to the shredded leaves and shredded stems of the cigarette formula used. The formula shredded leaves and shredded stems are dried and crushed through a 40-mesh sieve. Tobacco sticks are equilibrated for 48 hours in an environment of 22°C±1°C and relative humidity of 60%±3%. The moisture content of each sample was determined by the oven method.

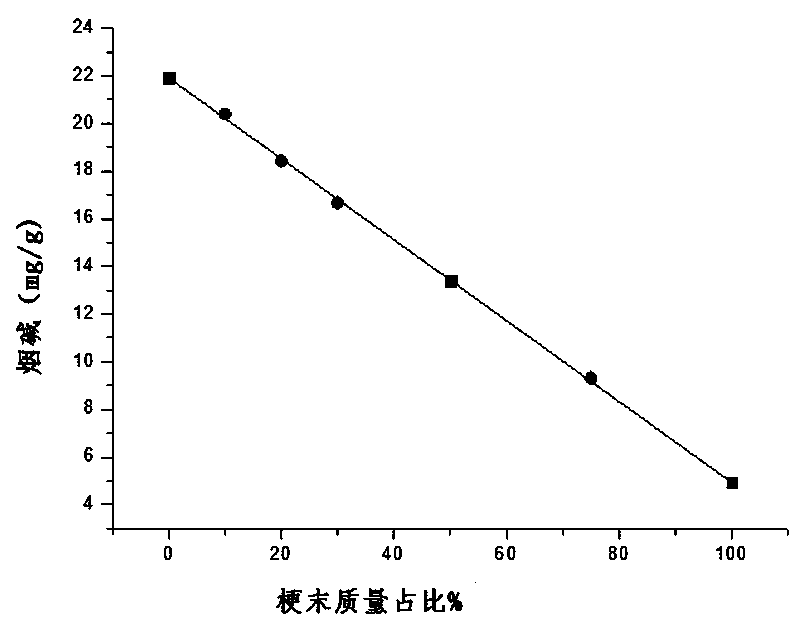

[0032] On a dry basis, the formula shredded leaf powder and cut stem powder are mixed according to a certain mass ratio, and the prepa...

Embodiment 2

[0046] A method for evaluating the mixing uniformity of cigarette raw materials based on design values, comprising the following steps:

[0047] (1) Sample collection: Take the shredded leaves and shredded stems of the formula in Example 1, and prepare cigarette samples according to the mixed design value of shredded stems at 30%.

[0048] (2)-(7) are the same as embodiment 1.

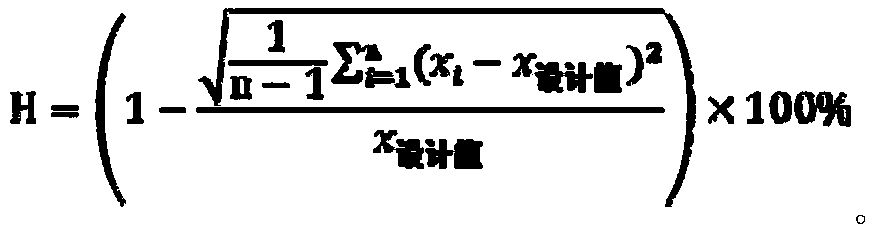

[0049] (8) Mixing uniformity of shredded tobacco stems: Determine the theoretical design value of nicotine according to the mixing design standard, select cigarettes at 10 sampling points in one batch, and randomly select 5 cigarettes at each sampling point, a total of 50 samples , removed the filter rod and cigarette paper, measured the dry base nicotine content of cut tobacco in each sample, and substituted it into the model to calculate the design nicotine value, and the relative standard deviation (RSD) was 4.2%, indicating that the method had high precision; The mixing uniformity of the cigarette...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com