Carbonyl iron powder core with magnetic conductivity of 35

A technology of carbonyl iron powder and carbonyl iron, which is applied in the field of materials, can solve problems such as burn-in and inability to use, and achieve the effect of reduced loss and good surface coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

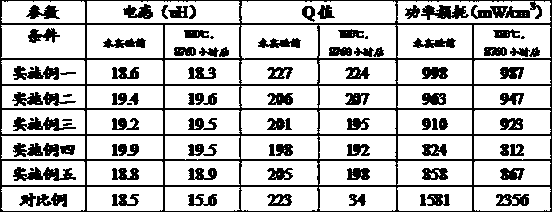

Embodiment 1

[0030] Select carbonyl iron powder with a purity of more than 97.5% as the raw material iron powder, the particle size is: D10=1.5~3.5 microns, D50=3.0~5.5 microns, D90=6.0~9.5 microns, with phosphoric acid alcohol solution, the concentration is 2wt%, Potassium dichromate aqueous solution, the concentration is 6wt%.

[0031] Mix and stir potassium dichromate aqueous solution and carbonyl iron powder, at the same time slowly add phosphoric acid alcohol solution to it, stirring time is 1 hour, stir at 70 degrees Celsius until the powder is dry, and then bake at 150 degrees Celsius for 90 minutes. The ratio of potassium dichromate aqueous solution to carbonyl iron powder is 5%. The ratio of phosphoric acid alcohol solution to carbonyl iron powder is 15%.

[0032] Add the mica powder into the alcohol liquid, mix well to form a uniform suspension liquid, then add the mixed liquid to the dried powder in the previous step, and stir until the powder is dry. The weight ratio of mica ...

Embodiment 2

[0037] The difference between this example and Example 1 is that the mica powder is replaced by kaolin and diatomite, the weight ratio of kaolin to carbonyl iron powder is 0.6%, and the weight ratio of diatomite to carbonyl iron powder is 0.6%. Use silica sol instead of silica-alumina sol, and add silica sol to carbonyl iron powder at a ratio of 4%. Add 0.3% lithium stearate as lubricant.

[0038] at 10 / cm 2 Under high pressure, it is pressed into iron powder core. The heat treatment condition is nitrogen, the heat treatment temperature is 500 degrees centigrade, and the time is 60 minutes.

[0039] Use HP4284A to test inductance, Q value, test condition 100kHz1V, N=20 turns, inductance is 19.4uH, Q=206, loss 963mW / cm 3 (50kHz / 100mT). After placing the iron powder core at 180 degrees Celsius for 8760 hours, the inductance of the iron powder core is 19.6uH, the Q value is 207, and the loss is 947 mW / cm 3 (50kHz / 100mT).

Embodiment 3

[0041] The difference between this example and Example 1 is that mica powder is replaced by diatomite, and the weight ratio of diatomite to carbonyl iron powder is 0.9%. Use silica sol instead of silica-alumina sol, and add silica sol to carbonyl iron powder at a weight ratio of 5%. Add 0.3% lithium stearate as lubricant.

[0042] at 12 / cm 2Under high pressure, it is pressed into iron powder core. The heat treatment condition is nitrogen, the heat treatment temperature is 600 degrees centigrade, and the time is 60 minutes.

[0043] Use HP4284A to test inductance, Q value, test condition 100kHz 1V, N=20 turns, inductance is 19.2uH, Q=201, loss 910mW / cm 3 (50kHz / 100mT). After placing the iron powder core at 180 degrees Celsius for 8760 hours, the inductance of the iron powder core is 19.5uH, the Q value is 195, and the loss is 923 mW / cm 3 (50kHz / 100mT).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com