Insulating protective film coating and preparation method thereof

A technology for protective films and coatings, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as reducing the surface resistance of electrical and electrical equipment, reducing the surface resistance of insulators, and increasing leakage current, etc. Achieve the effect of improving smooth cleaning and insulation level, alleviating rust and salt corrosion, and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

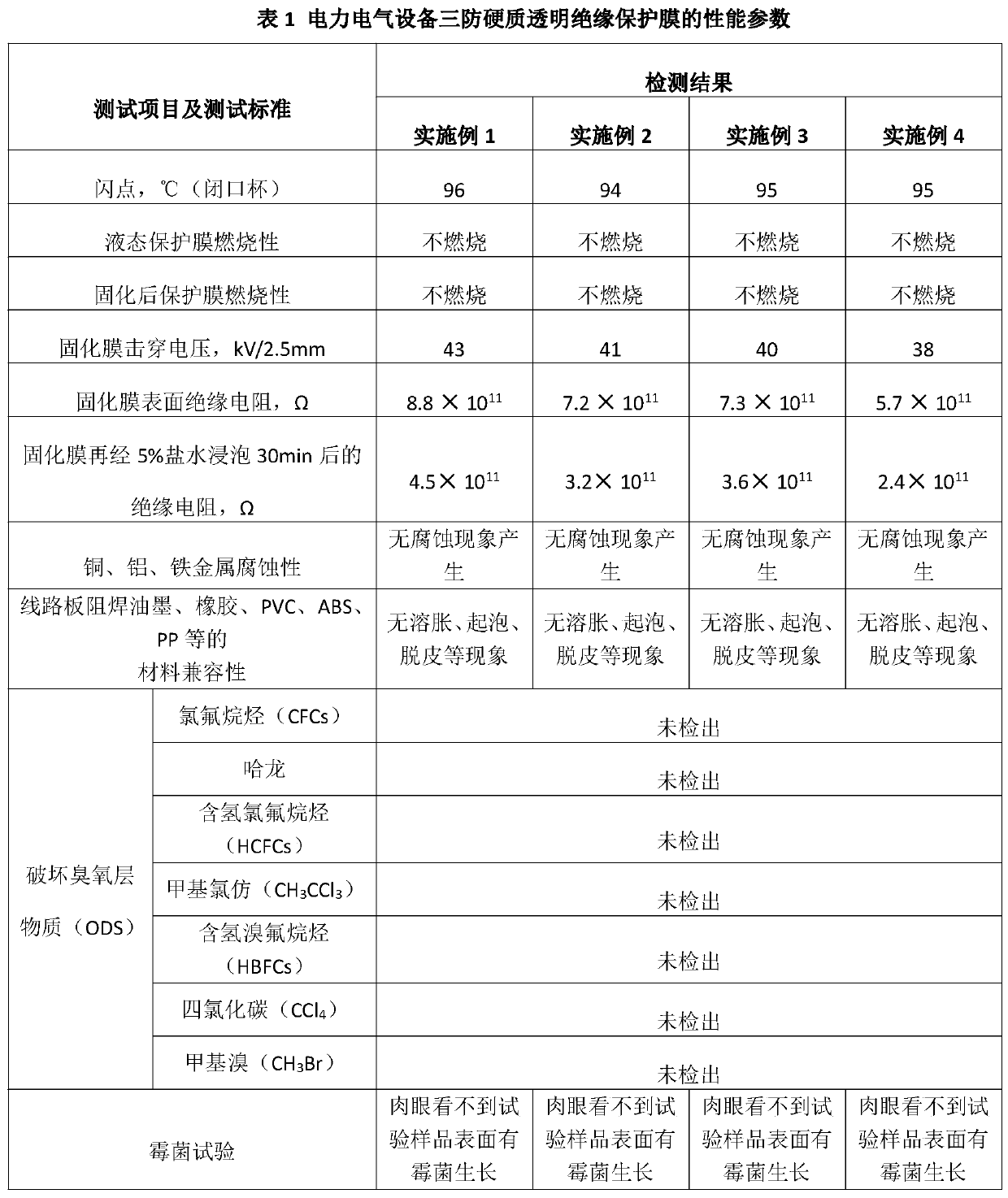

Examples

preparation example Construction

[0027] In addition, the preparation method of a kind of above-mentioned insulating protective film paint that the present invention also proposes, comprises the following steps:

[0028] Primary mixing: Weigh the nonafluorobutyl ethyl ether according to the weight percentage and put it into a closed reaction kettle, then add the propylene glycol methyl ether and the D100 solvent oil weighed according to the weight percentage in sequence, at a speed of 50 Stir continuously under the state of -80 rpm until the mixture is homogeneous to obtain the first mixture.

[0029] In the primary mixing step, the purpose of mixing the above three substances to obtain the first mixture is to fully mix the components of the solvent to prevent subsequent insufficient dissolution of the FEVE fluororesin or secondary precipitation.

[0030] Secondary mixing: add the FEVE fluororesin to the first mixture at a speed of 120-180 rpm according to the ratio of the weight percentage, and stir continuousl...

Embodiment 1

[0035] Weigh 5% of FEVE fluororesin, 75% of nonafluorobutyl ether, 6% of propylene glycol methyl ether, and 9% of D100 solvent oil according to weight percentage. Prepare the insulating protective film coating according to the following preparation steps:

[0036] Weigh nonafluorobutyl ethyl ether in a closed reaction kettle according to the weight percentage, then add propylene glycol methyl ether and D100 solvent oil in sequence, and continuously stir at a speed of 60 rpm for 10 minutes to make it evenly mixed;

[0037] Add FEVE fluororesin into the above reaction kettle at the speed of 150 rpm according to the stated ratio, and stir continuously at this speed for 15 minutes;

[0038] After the preparation is completed according to the above steps, it is then homogenized and stirred at a speed of 450 rpm or more for 15 minutes to obtain a uniform and transparent three-proof hard transparent insulating protective film coating for electrical and electrical equipment.

Embodiment 2

[0040] Weigh 8% of FEVE fluororesin, 80% of nonafluorobutyl ethyl ether, 5% of propylene glycol methyl ether, and 7% of D100 solvent oil according to weight percentage. Prepare the insulating protective film coating according to the following preparation steps:

[0041] Weigh nonafluorobutyl ethyl ether in a closed reaction kettle according to the weight percentage, then add propylene glycol methyl ether and D100 solvent oil in sequence, and continuously stir at a speed of 60 rpm for 10 minutes to make it evenly mixed;

[0042] Add FEVE fluororesin into the above reaction kettle at the speed of 150 rpm according to the stated ratio, and stir continuously at this speed for 15 minutes;

[0043] After the preparation is completed according to the above steps, it is then homogenized and stirred at a speed of 450 rpm or more for 15 minutes to obtain a uniform and transparent three-proof hard transparent insulating protective film coating for electrical and electrical equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com