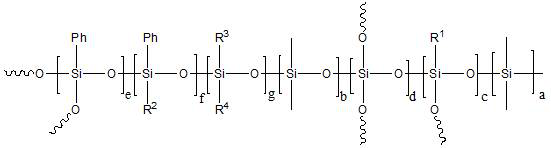

A kind of one-component room temperature curing silicone resin containing MQ structural unit and its preparation method

A MQ silicone resin, room temperature curing technology, applied in the field of silicone resin, to achieve the effect of increased strength, good transparency, and high curing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

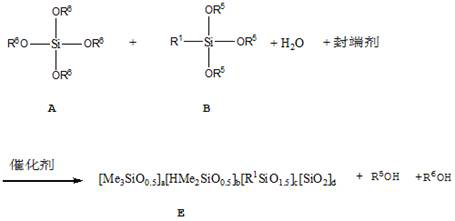

Method used

Image

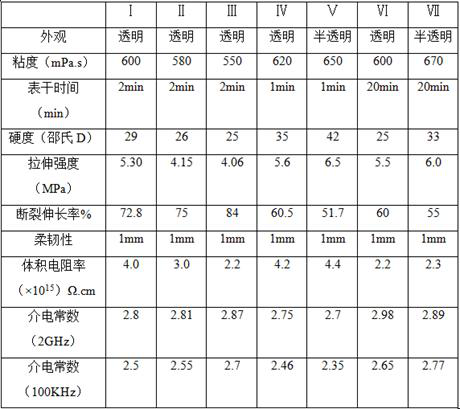

Examples

Embodiment 1

[0050] Add 790g of phenyltrimethoxysilane and 1040g of ethyl orthosilicate to a 3L three-necked flask, raise the temperature to 30°C, add 300g of hydrochloric acid aqueous solution with a mass fraction of 0.01% to start hydrolysis, and when the temperature rises to 70°C, add 240g MM (Chinese name is: hexamethyldisiloxane) and 60g hydrogen-containing end-capping agent, keep the temperature at 70 ° C for 4 hours, stop the reaction, add toluene for extraction, static layering, and vacuum distillation to remove the solvent to obtain a white Hydrogen-containing MQ resin E in solid powder form.

[0051] Add 1000g of methylphenyl ring body, 1000g of hydroxy silicone oil, 1g of tetramethylammonium hydroxide into a 3L three-necked flask, and raise the temperature to 65°C to balance the reaction. When the viscosity rises to about 200mpa.s and the reaction liquid becomes transparent, Raise the temperature to 140°C, keep the reaction for 1h, and remove the low boilers under reduced pressu...

Embodiment 2

[0054] Take 100g of hydrogen-containing MQ resin E described in Example 1 and dissolve it in 200g of toluene solvent, add 325g of F, 0.078g of Pt catalyst, keep the reaction temperature at 80~90°C, react for 1h, add 55g of methyltrimethoxysilane and 0.21g of Dibutyltin dilaurate, reflux for 2 hours, lower the temperature, take off the vacuum, and adjust the solid content to 70%. A room temperature curing silicone resin II was obtained.

Embodiment 3

[0056] Take 100g of the above-mentioned hydrogen-containing MQ resin E described in Example 1 and dissolve it in 200g of toluene solvent, add 350g of F, 0.0812g of Pt catalyst, keep the reaction temperature at 80~90°C, react for 1h, add 60g of methyltrimethoxysilane and 0.225g of Isopropyl titanate, reflux for 2 hours, lower the temperature, take off the vacuum, and adjust the solid content to 70%. A room temperature curing silicone resin III was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com