A silane coupling agent hydrolyzate and its application in polyaniline attapulgite nanocomposite coating

A silane coupling agent, attapulgite technology, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, dyed organosilicon compound treatment, etc., can solve the problems of low stability reactivity, poor reactivity stability, etc. , stabilize the reactivity, improve the effect of wetting and dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] (1) Preparation of attapulgite slurry: add attapulgite raw material to deionized water to make a slurry whose quality of attapulgite accounts for 20% of the mass of deionized water;

[0038] (2) Preparation of inorganic acid-doped polyaniline / attapulgite nano-conductive composite material: under the condition of constant stirring, add aniline monomer to the above slurry, the quality of aniline monomer accounts for 40% of the attapulgite quality, Add inorganic acid to the slurry again, the molar ratio of inorganic acid to aniline monomer is 10:1, then slowly drop into the above slurry a solution of oxidizing agent with a concentration of 1.2mol / L, the molar ratio of oxidizing agent to aniline monomer 0.5:1, oxidative polymerization for 12 hours, polymerization temperature is 45°C;

[0039] (3) De-doping of inorganic acid-doped polyaniline / attapulgite nano-conductive composite material: the polyaniline / attapulgite nano-conductive composite material doped with inorganic ac...

Embodiment 1

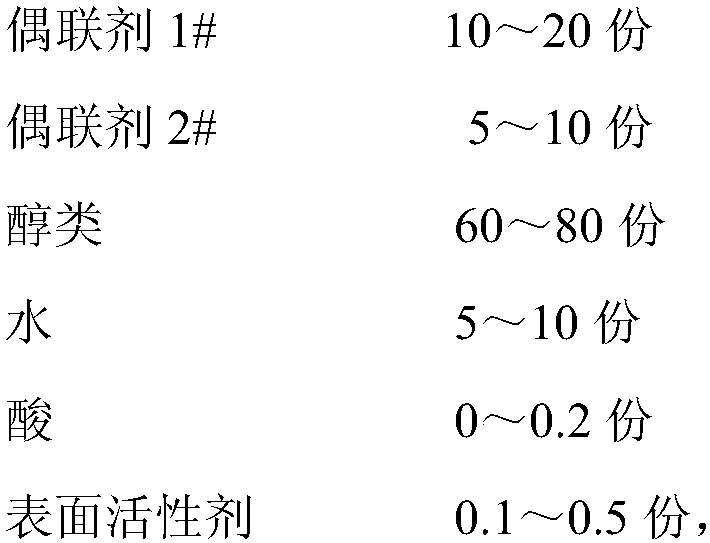

[0052] Calculated in parts by weight:

[0053] (1) Add 9.4 parts of deionized water, 50 parts of methanol, and 15 parts of isopropanol into the reaction kettle, then add 0.2 parts of acetic acid, 0.2 parts of tartaric acid and 0.2 parts of nonionic surfactant TX-10, and stir well Obtain alcohol aqueous solution;

[0054] (2) Slowly add 20 parts of trimethoxysilane dropwise to the aqueous alcohol solution in step (1) under stirring at 25°C and 60 rpm, and continue to stir and hydrolyze at 25°C for 60 minutes after the dropwise addition;

[0055] (3) Slowly add 5 parts of 3-glycidyl etheroxypropyl trimethoxysilane dropwise to the system obtained in step (2) under the stirring state of 25°C and 60rpm. Stir and hydrolyze for 30 minutes to prepare a coupling agent hydrolyzate, which can be placed stably for 48 hours (25°C);

[0056] Put the polyaniline / attapulgite nanomaterial prepared above into a solid mixer, and spray the coupling agent hydrolyzate prepared in this embodiment,...

Embodiment 2

[0059] Calculated in parts by weight:

[0060] (1) Add 7.5 parts of deionized water, 50 parts of ethanol, and 15 parts of isopropanol into the reaction kettle, then add 0.5 parts of nonionic surfactant TX-10, and stir evenly to obtain an aqueous alcohol solution;

[0061] (2) Slowly add 20 parts of vinyltriethoxysilane dropwise to the aqueous alcohol solution in step (1) under stirring at 25°C and 60 rpm, and continue to stir and hydrolyze at 25°C for 60 minutes after the dropwise addition;

[0062] (3) Slowly add 7 parts of γ-aminopropylmethyldiethoxysilane dropwise to the system obtained in step (2) under the stirring state of 25°C and 60rpm. Stir and hydrolyze for 30 minutes to prepare a coupling agent hydrolyzate, which can be placed stably for 48 hours (25°C);

[0063] Put the polyaniline / attapulgite nanomaterial prepared above into a solid mixer, and spray the coupling agent hydrolyzate prepared in this embodiment, which accounts for 2% by weight of the nanomaterial, on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com