Exhaust arrangement for outboard marine drive engine

An engine and marine technology, applied in the direction of propulsion engine, engine components, engine cooling, etc., can solve the problems of complex structure, increased manufacturing cost, engine output loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

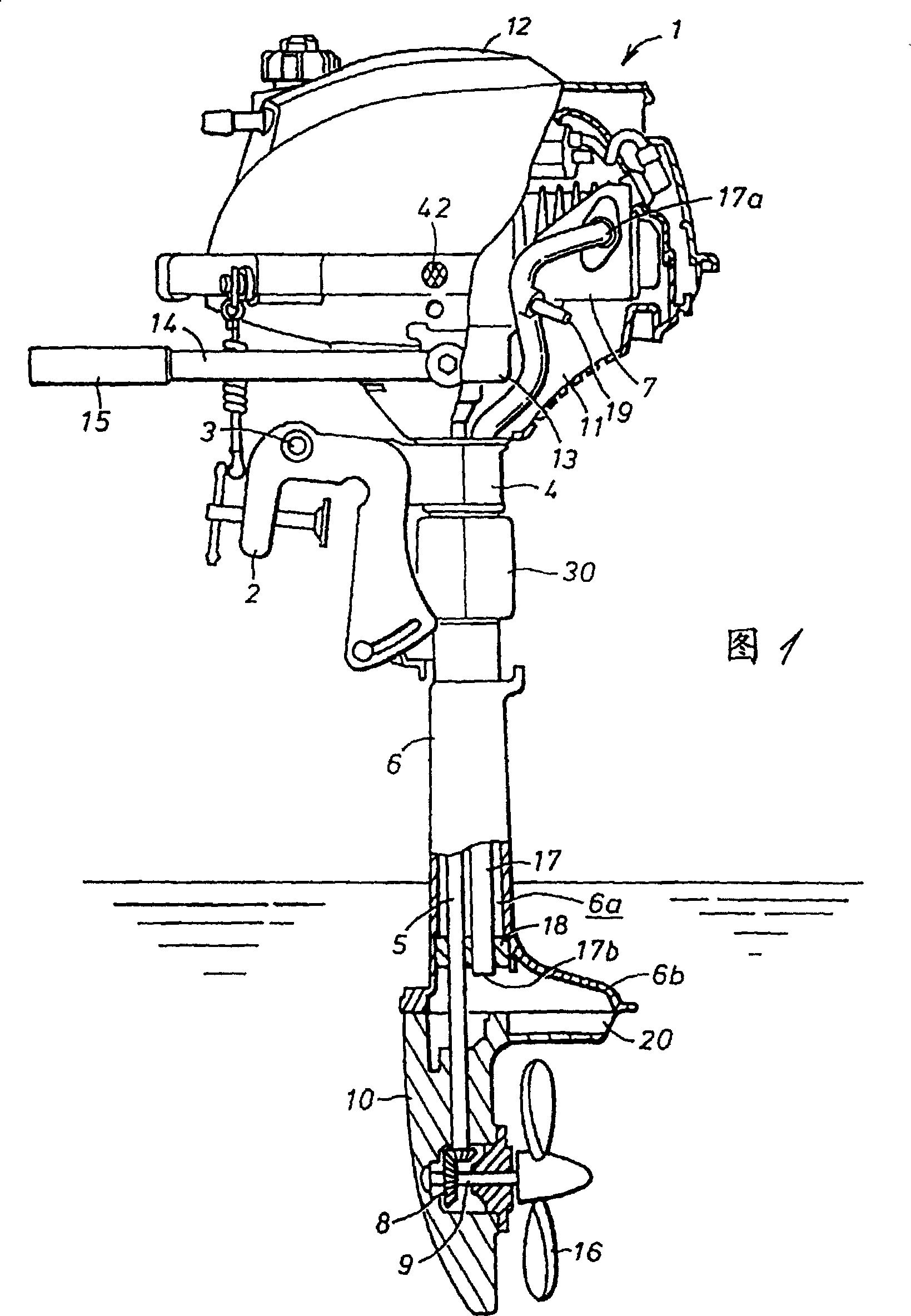

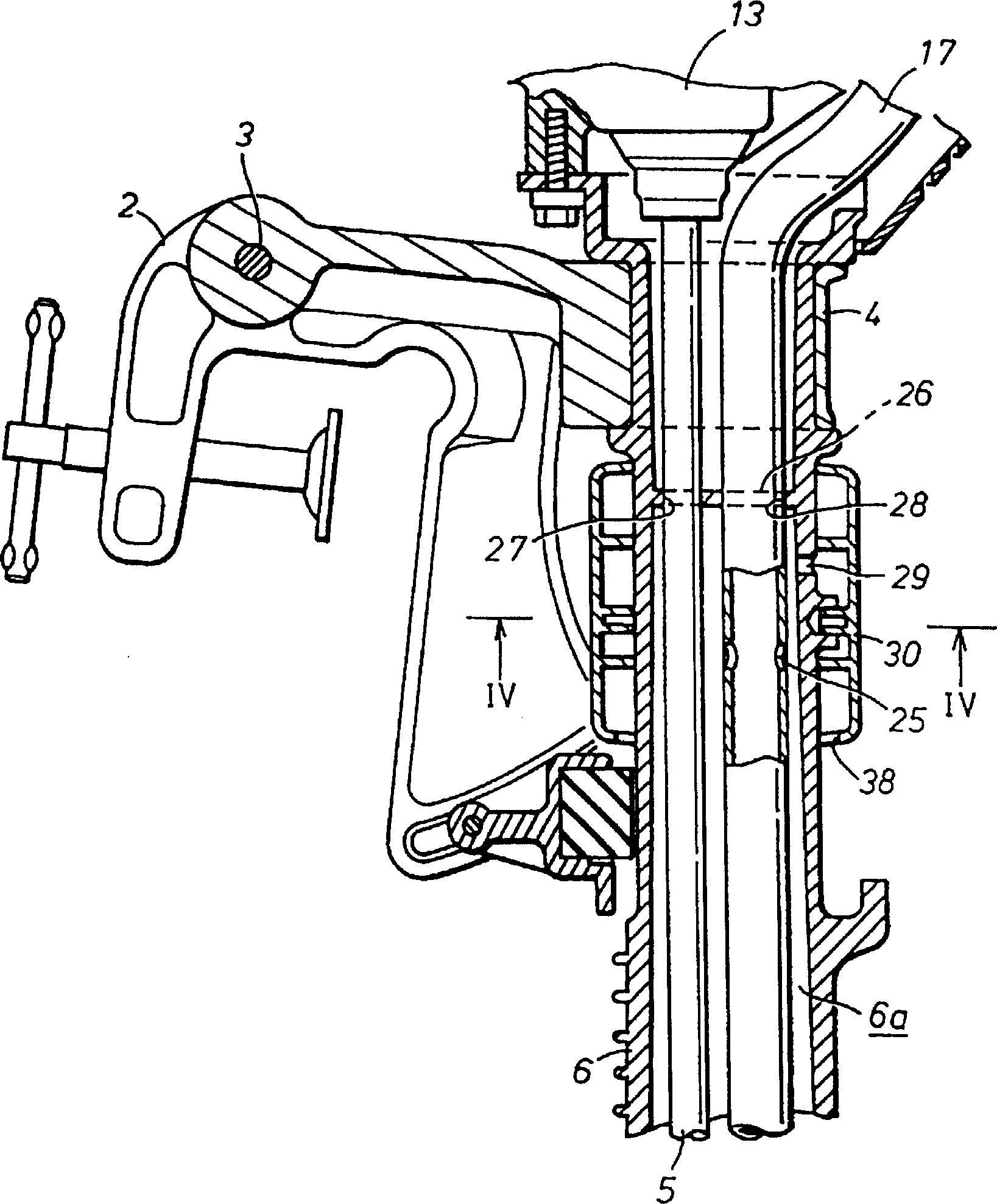

[0014] Fig. 1 is a side view generally showing an external marine drive unit embodying the present invention. The outboard marine drive 1 is suitable for connection to the transom of a boat (not shown in the figure) with a rear support 2 having a fastening function. The swivel housing 4 is connected to the rear support 2 by a turning shaft 3 extending horizontally and across the width of the boat. The rotating housing 4 itself supports a tubular extension housing 6 inside which houses a vertically extending drive shaft 5 . The swivel housing 4 allows the body of the outboard boat drive to rotate 360 degrees relative to the rear support 2 or the boat about a vertical steering axis.

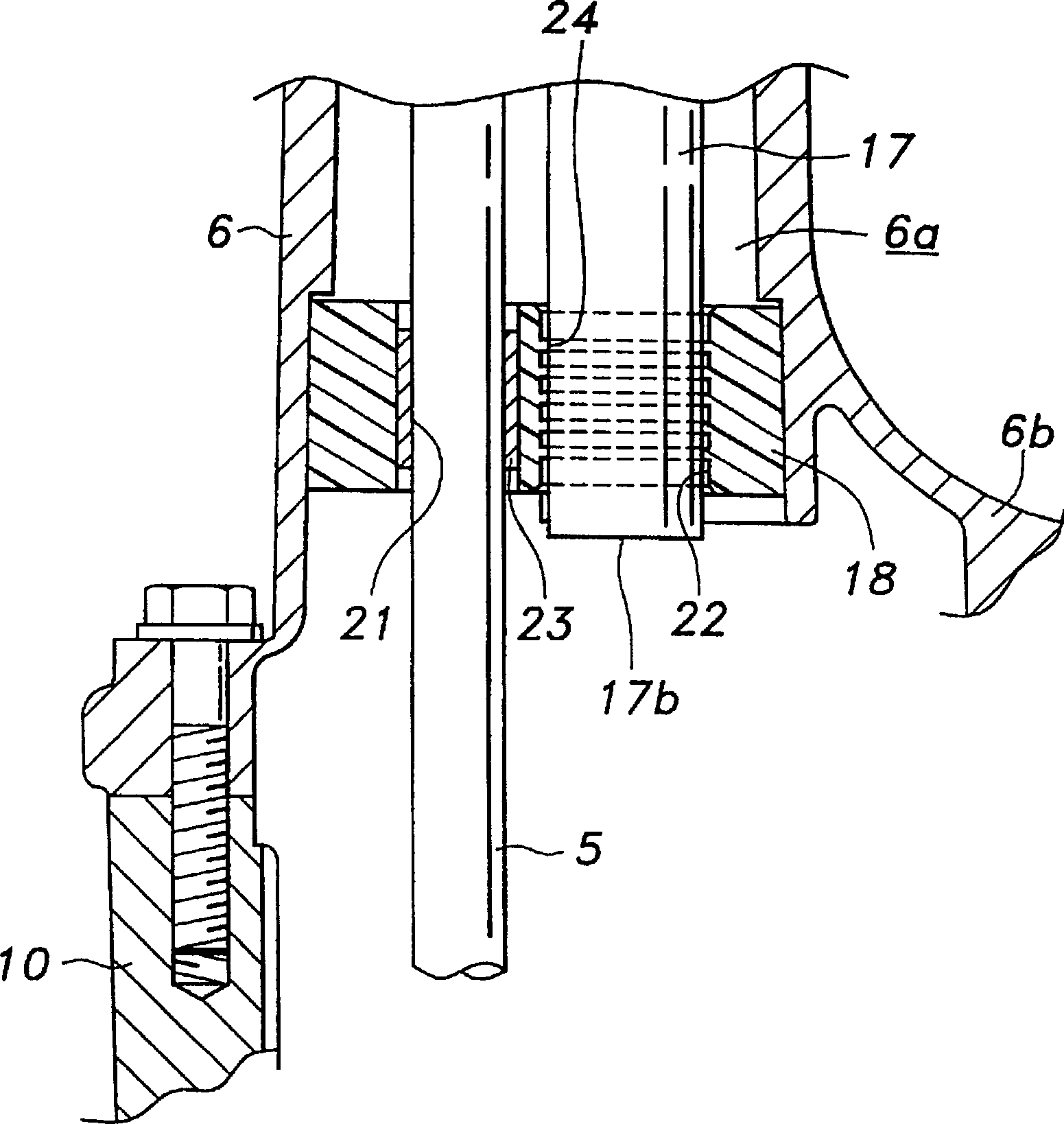

[0015] The upper end of the extension housing 6 is connected to an internal combustion engine 7, and the lower end of the extension housing 6 is connected to a bevel gear mechanism housing a propeller shaft 9 and for transmitting rotational power from the lower end of the drive shaft 5 to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com