Unitized self-cleaning type filtering device for organic waste gas treatment

A technology of organic waste gas and filter device, which is applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of increasing loading and unloading, transportation, replacement and other work procedures, frequent replacement of activated carbon, and increased operating costs, etc., to achieve the adsorption effect. Good, excellent resistance to mechanical fatigue, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

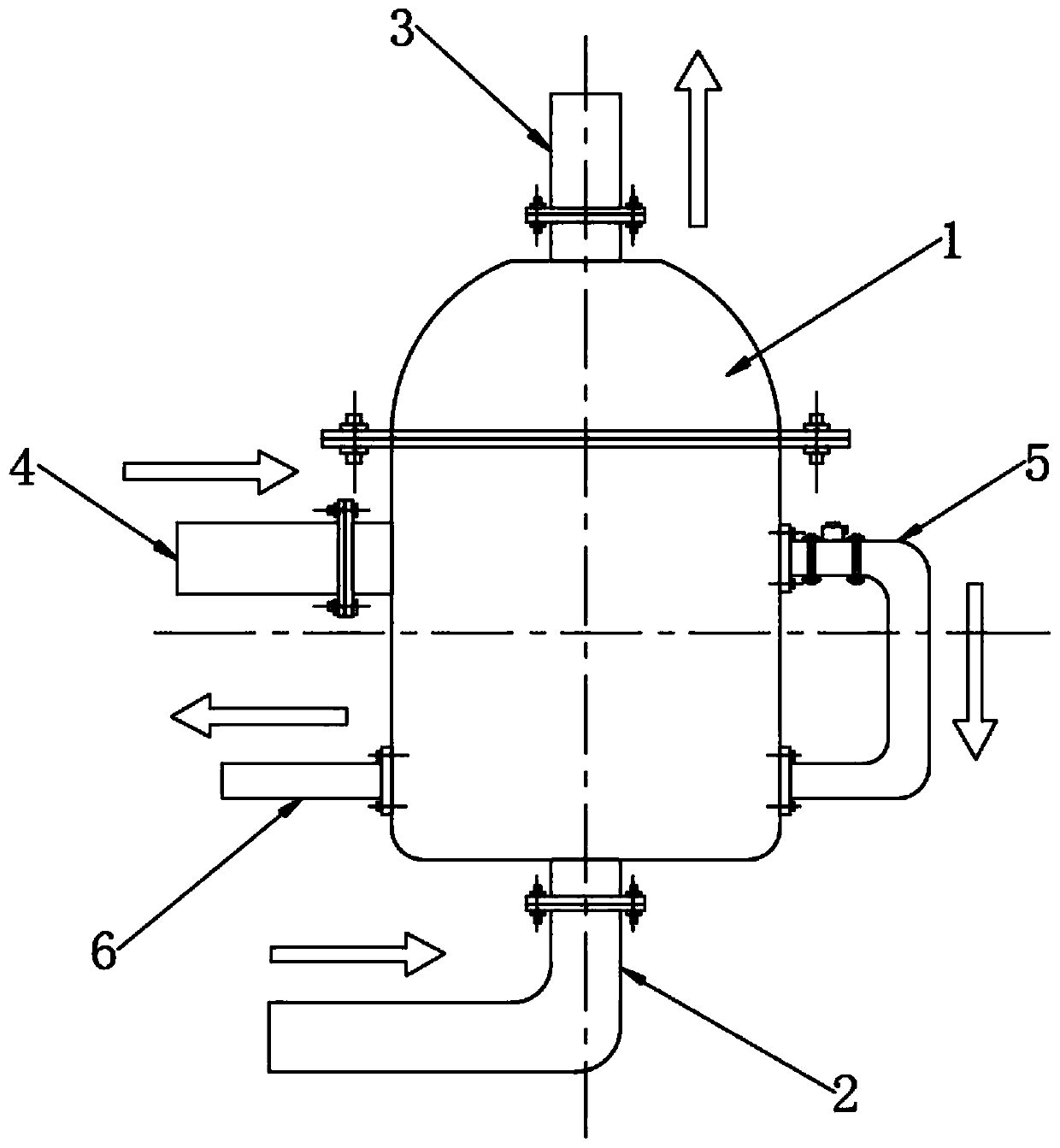

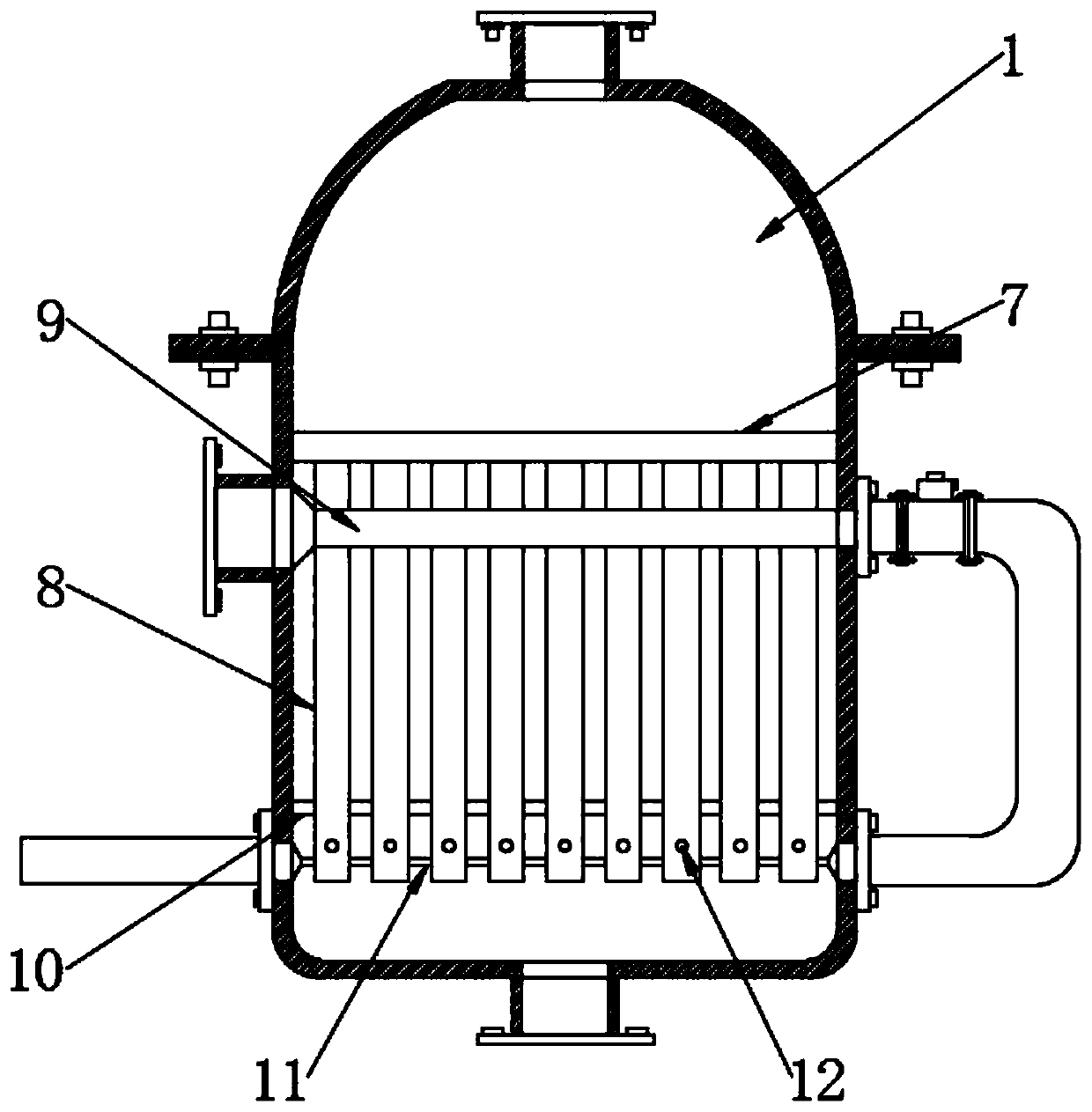

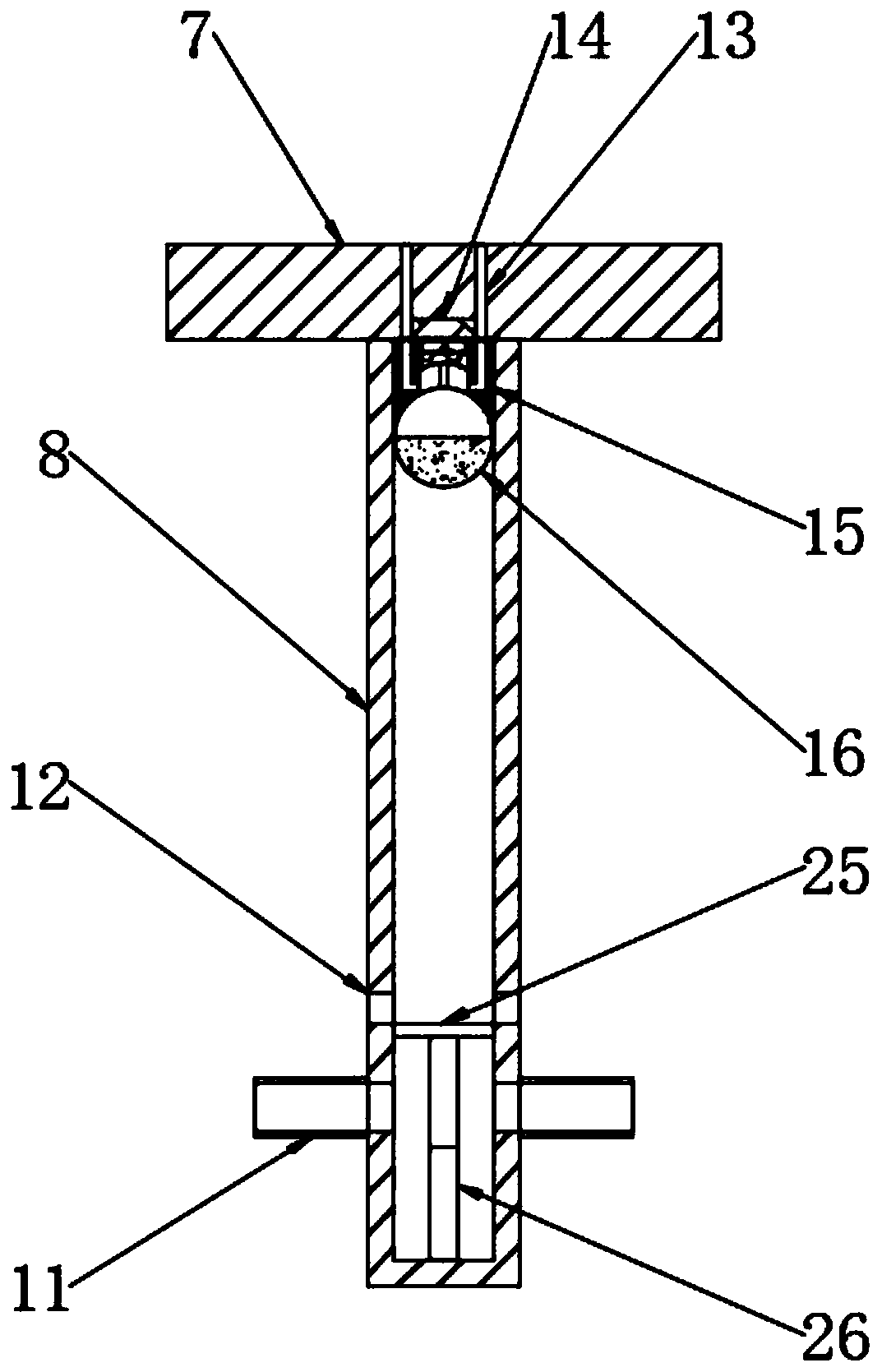

[0044] see Figure 1-2 , a unitized self-cleaning filter device for organic waste gas treatment, comprising an adsorption tank 1, the upper and lower ends of the adsorption tank 1 are respectively fixedly connected with an outlet pipe 3 and an intake pipe 2, and the adsorption tank 1 is fixedly connected with a built-in mounting plate 7, The built-in mounting plate 7 is fixedly connected with a plurality of uniformly distributed heat-conducting ventilation pipes 8, and the lower side of the built-in mounting plate 7 is provided with an air baffle 10, and the air baffle 10 is set on a plurality of heat-conducting ventilation pipes 8, and the lower end of the heat-conducting ventilation pipe 8 There are a plurality of evenly distributed air intake holes 12, and the air intake holes 12 are located on the lower side of the air baffle plate 10, and the left and right ends of the adsorption tank 1 are respectively fixedly connected with the water inlet pipe 4 and the circulation pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com