Textile dye blending device convenient to move

A technology for textile dyes and dye boxes, which is applied in the field of textile printing and dyeing, can solve the problems of unqualified color matching, poor brilliance and saturation, and unprotected personal hygiene of staff, and achieves the effects of accelerated melting and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

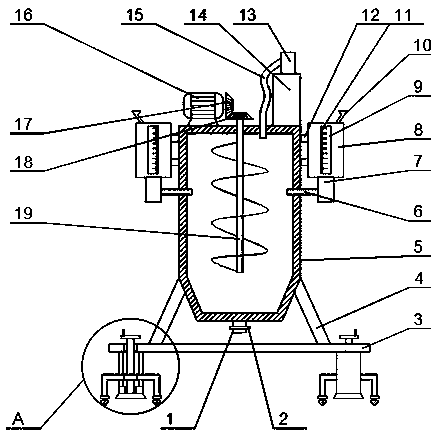

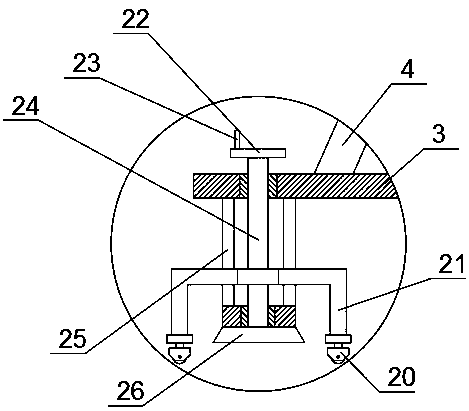

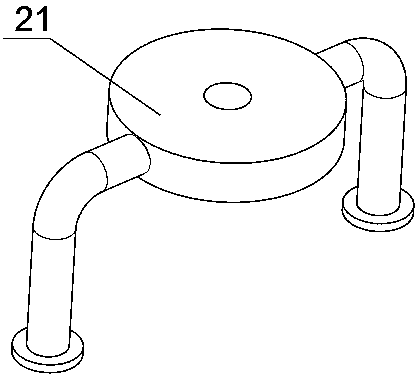

[0021] see Figure 1-3 , an easy-to-move textile dye blending device, comprising a mixing box 5, a motor 16, a water pump 13 and a powder pump 7, the output end of the motor 16 is fixedly connected to the first bevel gear 17, and the first bevel gear 17 meshes with the first bevel gear 17. Two bevel gears 18, the lower end of the mixing box 5 is fixedly connected to the discharge port 1, and the discharge port 1 is provided with a discharge valve 2, which is provided with a discharge port 1 to facilitate the discharge of the prepared dye. To control the discharging process of dyestuff, the lower side of the mixing box 5 is fixedly connected to several support rods 4, the lower end of the support rods 4 is fixedly connected to the support plate 3, and the support rod 4 is held up to a certain height, which is convenient for using the discharge port 1, and has support at the same time. For the purpose of strengthening, a supporting plate 3 is provided to facilitate the installat...

Embodiment 2

[0024] see figure 1 The difference between this implementation and the above-mentioned Embodiment 1 is that the upper end of the threaded column 24 is fixedly connected to the turntable 22, the upper side of the turntable 22 is fixedly connected with a rocker 23, and the turntable 22 and the rocker 23 are provided to facilitate the threaded column 24. Rotating, it is convenient to adjust the height of the bracket 21 .

[0025] The working principle of the present invention is as follows: when the textile dye preparation device is easy to move, when the textile dye needs to be prepared, the rocker 23 is used to rotate the threaded column 24 to move the support 21 down, lift the device, and then pass the roller 20 Move the device to a suitable position, then reversely rotate the threaded column 24, raise the bracket 21, use the outrigger 25 to support the device, and then through the feeding port 10, the dyeing powder of different colors is fed into different dye boxes 8 , obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com