Preparation method and application of MnxOy material

A mixed solution and distilled water technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of pollutants, teratogenicity, Threats to human health and safety and other issues, to achieve the effect of repeatable harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] mn x o y The preparation of materials, the method is as follows:

[0031] 1) Dissolve 2 mmol of manganese chloride tetrahydrate in a mixed solution of 25 mL of distilled water and 20 mL of glycerol and keep stirring for 25 min to form a mixed solution 1;

[0032] 2) Under the condition of magnetic stirring, add 10 mL of 2 mol / L NaOH solution dropwise to the above mixed solution 1 and continue to stir for 3 h to form mixed solution 2;

[0033] 3) Pour the mixture 2 into a 100ml reaction kettle, put it in an oven, and keep the temperature at 150°C for 24 hours;

[0034] 4) After the reaction is completed, cool to room temperature, centrifuge the obtained precipitate, wash 3 times with distilled water, wash 2 times with ethanol, and dry at 60°C for 5.5 hours to obtain brown-yellow Mn x o y Material.

Embodiment 2

[0036] mn x o y The preparation of materials, the method is as follows:

[0037] 1) Dissolve 2 mmol of manganese chloride tetrahydrate in a mixed solution of 15 mL of distilled water and 30 mL of glycerol and keep stirring for 25 min to form a mixed solution 1;

[0038] 2) Under the condition of magnetic stirring, add 10 mL of 2 mol / L NaOH solution dropwise to the above mixed solution 1 and continue to stir for 3 h to form mixed solution 2;

[0039] 3) Pour the mixture 2 into a 100ml reaction kettle, put it in an oven, and keep the temperature at 150°C for 24 hours;

[0040] 4) After the reaction is completed, cool to room temperature, centrifuge the obtained precipitate, wash 3 times with distilled water, wash 2 times with ethanol, and dry at 80°C for 9.5 hours to obtain brown-yellow Mn x o y Material.

Embodiment 3

[0042] mn x o y The preparation of materials, the method is as follows:

[0043] 1) Dissolve 2 mmol of manganese chloride tetrahydrate in a mixed solution of 15 mL of distilled water and 30 mL of glycerol and keep stirring for 25 min to form a mixed solution 1;

[0044] 2) Under the condition of magnetic stirring, add 10 mL of 2 mol / L NaOH solution dropwise to the above mixed solution 1 and continue to stir for 3 h to form mixed solution 2;

[0045] 3) Pour the mixture 2 into a 100ml reaction kettle, put it in an oven, and keep the temperature at 150°C for 24 hours;

[0046] 4) After the reaction is completed, cool to room temperature, centrifuge the obtained precipitate, wash 3 times with distilled water, wash 2 times with ethanol, and dry at 60°C for 5.5 hours to obtain brown-yellow Mn x o y Material.

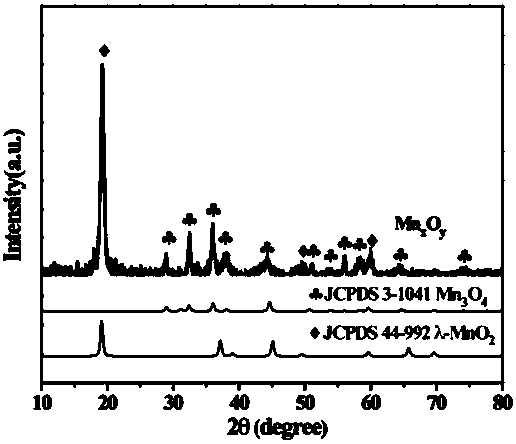

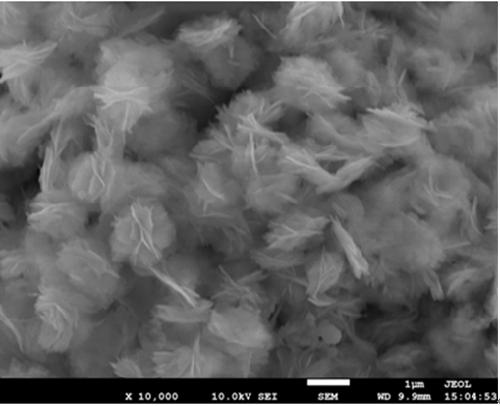

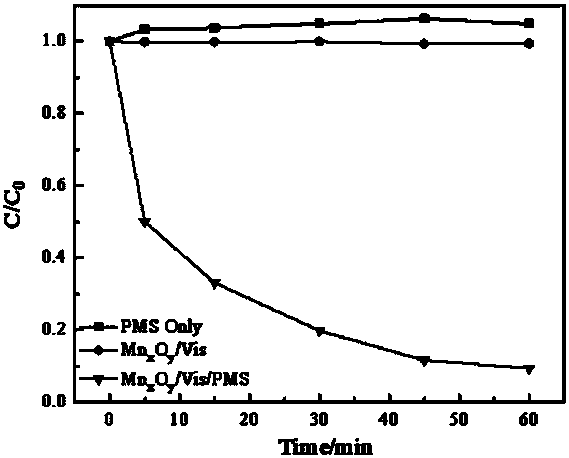

[0047] figure 1 shows Mn x o y The X-ray diffraction pattern of the material, it can be seen from the figure that the prepared Mn x o y The material is a composite of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com