Method for in-situ remediation of benzene series in soil through plant-microorganism-charcoal combined remediation technology

An in-situ restoration and joint restoration technology, applied in the restoration of contaminated soil, etc., can solve problems such as human injury, soil hazards, hazards, etc., and achieve the effects of small engineering, environmental improvement, and environmental pollution restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] 3. Preparation of biochar

[0037] Rinse the corn stalks with water to remove dirt and dust on the surface, cut into small pieces of 1-3cm, and air-dry for 3 hours under natural conditions; then put them in an oven at 80°C for 10 hours, take them out, crush them, put them in a crucible, and cover them Cover and seal, place in a muffle furnace, carbonize at 400°C for 6 hours, take it out after cooling to room temperature, grind, and pass through a 60-mesh sieve to obtain biochar.

[0038] 4. Sprinkle biochar in the soil containing benzene series, the amount of biochar spraying is 2-3kg / m 2 .

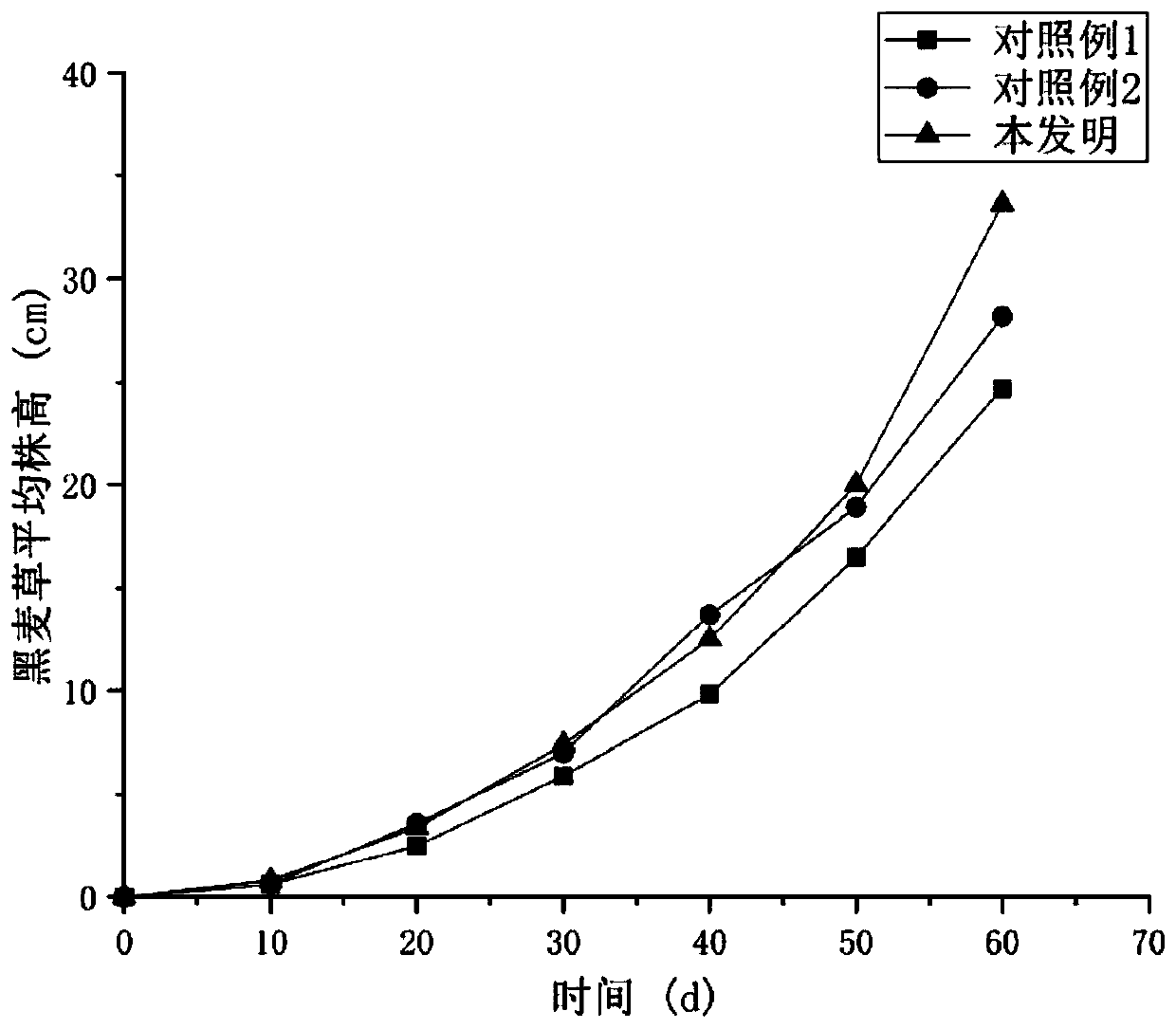

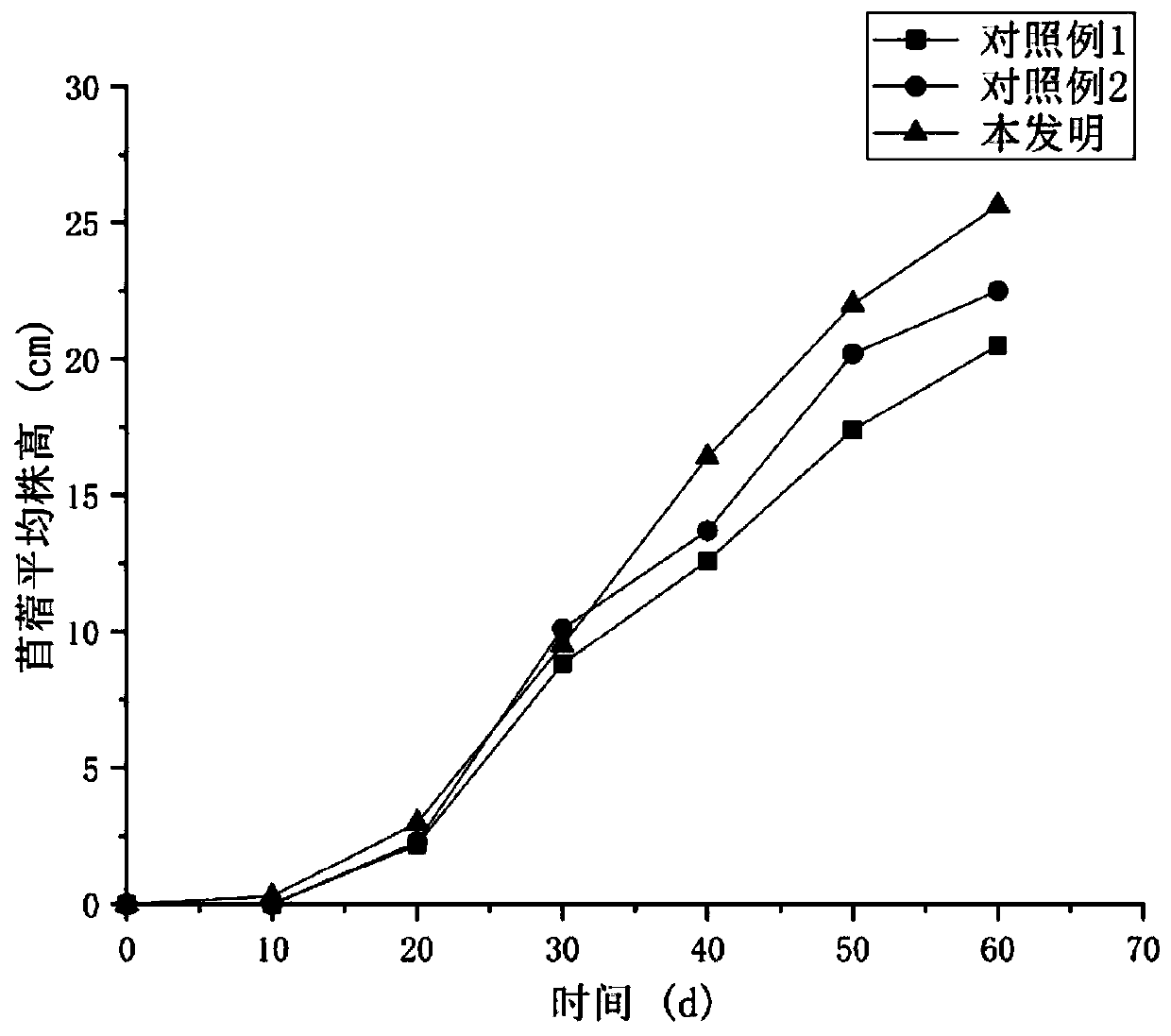

[0039] 5. Sow ryegrass seeds and alfalfa seeds impregnated with the fermented liquid of Rhizobium meliloti in the soil that has been sprinkled with biochar. 30cm, the sowing width is 5-10cm, the upper part of the seed is covered with soil 1-2cm, water once a day in the morning and evening from the 20th day after sowing, and water once a day from the 20th to 40th day; loosen the s...

Embodiment 1

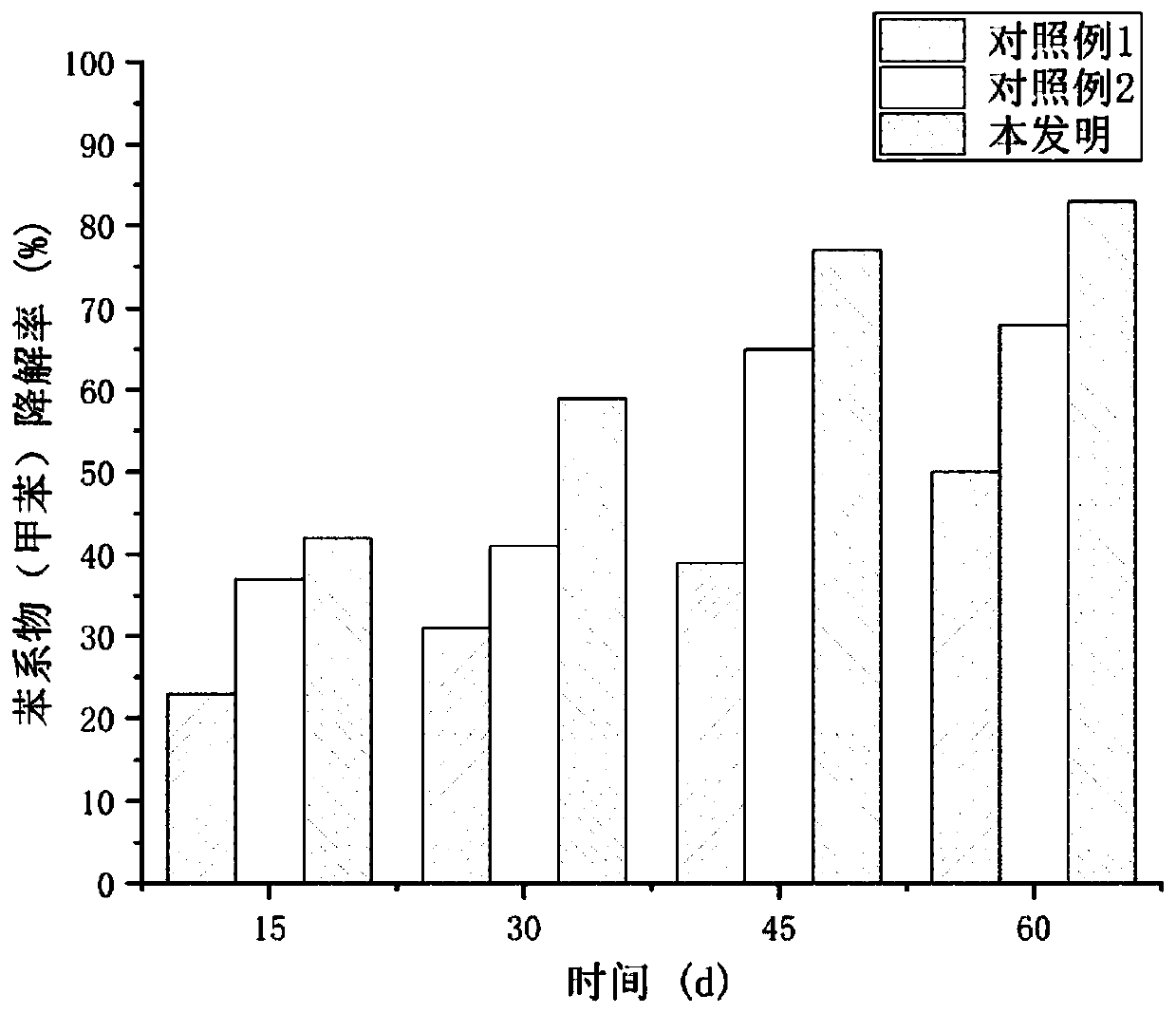

[0044] In this embodiment, the site of a waste tire refinery in Dingjia, Group 3, Xinkai Village, Jiguanshan Town, Fengcheng City, Dandong City, is used as the test site. The site covers an area of about 1200 square meters and has been tested to contain toluene. In order to show the remediation effect of toluene in the plant-microbial-biochar joint remediation soil of the present invention, the remediation test was carried out in the tire oil tank area, the eastern area of the drainage seepage pit and the western area of the drainage seepage pit respectively in the waste tire refinery site, each area Divide 3 test fields respectively, each test field specification is 20m * 10m, wherein one test field adopts the method of the present invention, and other two test fields are used as control experiments. The test lasted a total of 70 days, of which the plants were planted for 60 days.

[0045] One, the inventive method is as follows:

[0046] 1. Seed pretreatment

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com