Complex curved surface component forming device and method on the basis of magnetorheological elastomers

A magneto-rheological elastomer and complex curved surface technology, which is applied to engine components, mechanical equipment, etc., can solve problems such as large-scale accuracy, wall thickness distribution differences, and difficult forming control of complex curved surface components, so as to increase modulus and response Fast, the effect of improving the forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

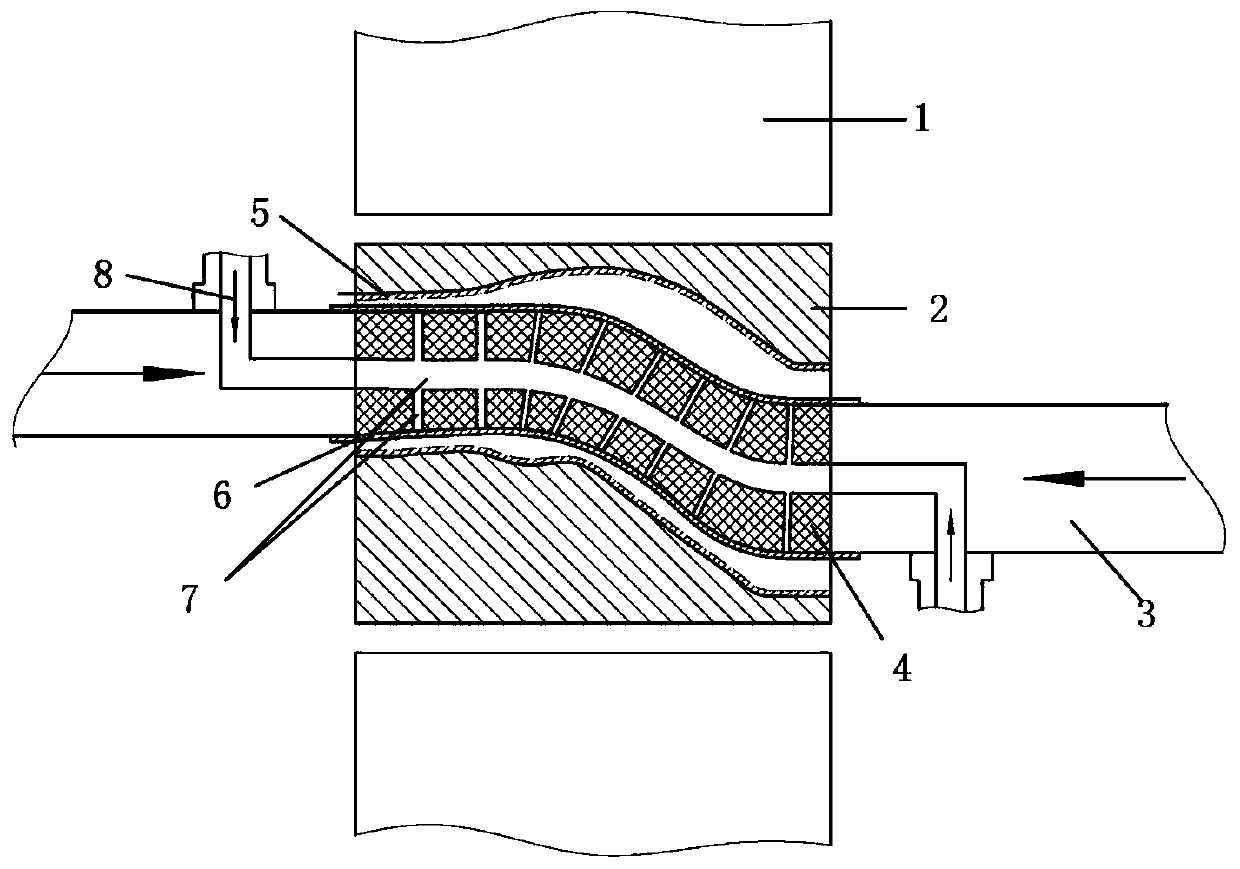

[0060] In the first step, the magnetorheological elastomer 4 with the through hole 7 is put into the tube blank 6, the content of magnetic particles at the corner of the magnetorheological elastomer 4 is higher than that at both ends, and the magnetic particles at the right end The content is higher than the left end, so that the deformation of the right end of the pipe is greater than that of the left end. At the same time, due to the large deformation at the corner, local high pressure is required here, and the number of through holes is also large. Put the tube blank 6 into the pipe with figure 1 The complex curved surface mold cavity shown in the figure is closed, and then the whole is placed on the working table of the bulging device, and the pressure head 3 presses the two ends of the magnetorheological elastomer 4 to form a seal;

[0061] The second step is to prefill the liquid through the high-pressure liquid input channel on the pressure head 3 to discharge the air in...

Embodiment 2

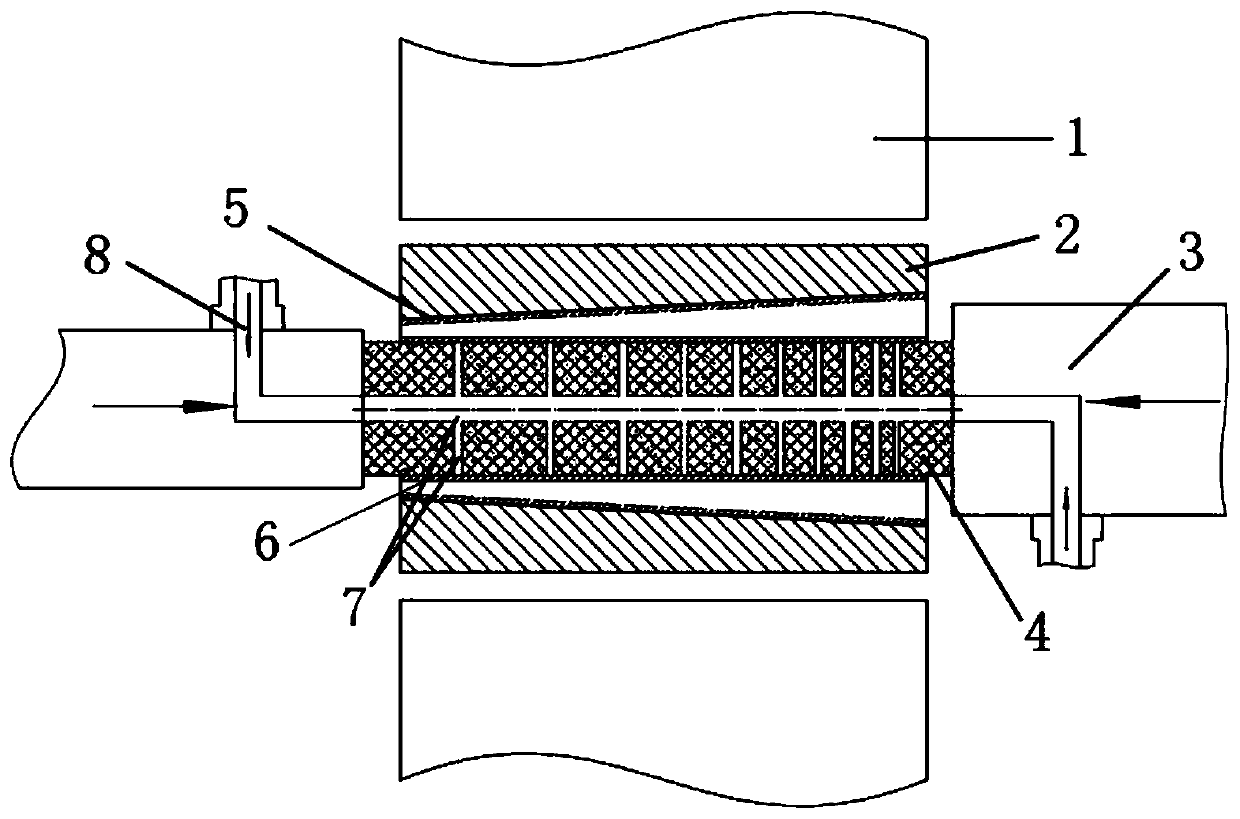

[0067] In the first step, the magnetorheological elastomer 4 with the through hole 7 is put into the tube blank 6. The magnetorheological elastomer 4 presents a gradient distribution of magnetic particle content in the axial direction, and the greater the deformation, the greater the magnetic particle content. High, the distance between the radial through-holes (from left to right) gradually decreases during the process of increasing the amount of deformation, put the tube blank 6 into the continuous shrinking mold cavity and close the mold, and then place the whole in the expansion On the working table of the shaped device, the pressure head 3 presses the two ends of the magnetorheological elastomer 4 to form a seal;

[0068] The second step is to discharge the air in the tube through the pre-filling liquid through the hole on the pressure head 3;

[0069] In the third step, the electromagnet is fixed on the bulging device and connected with a high-precision DC excitation pow...

Embodiment 3

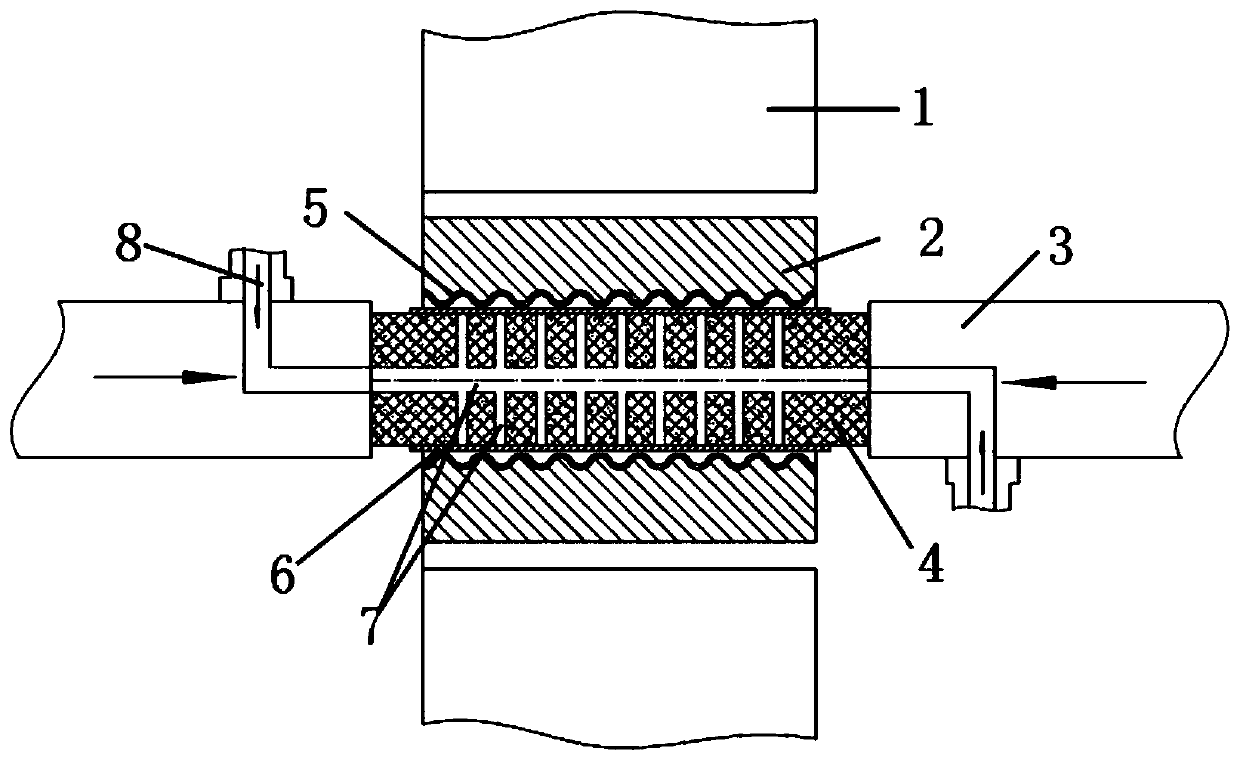

[0074] The first step is to put the magnetorheological elastomer 4 with the through hole 7 into the tube blank 6. The magnetorheological elastomer 4 has a higher magnetic particle content at the expansion joint than at the flat section, and a diameter is opened at each expansion joint. There are no radial through holes in the flat section, put the tube blank 6 into the bellows mold cavity and close the mold, and then place the whole on the workbench of the bulging device, and the pressure head 3 presses the magneto-rheological The two ends of the elastic body 4 form a seal;

[0075] The second step is to discharge the air in the tube through the pre-filling liquid through the hole on the pressure head 3;

[0076] In the third step, the electromagnet is fixed on the bulging device and connected with a high-precision DC excitation power supply;

[0077] The fourth step is to turn on the power, so that the magnetic field generated by the pole head 1 area of the magnetic field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com