Intermittent automatic lifting and transferring device for roll shaft machining

A technology of mechanical processing and transfer device, applied in the direction of lifting device, transportation and packaging, roller table, etc., can solve the problems of damaged roller shaft, high manufacturing cost, difficult transfer of roller shaft, etc., and achieve the effect of avoiding damage and convenient material blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

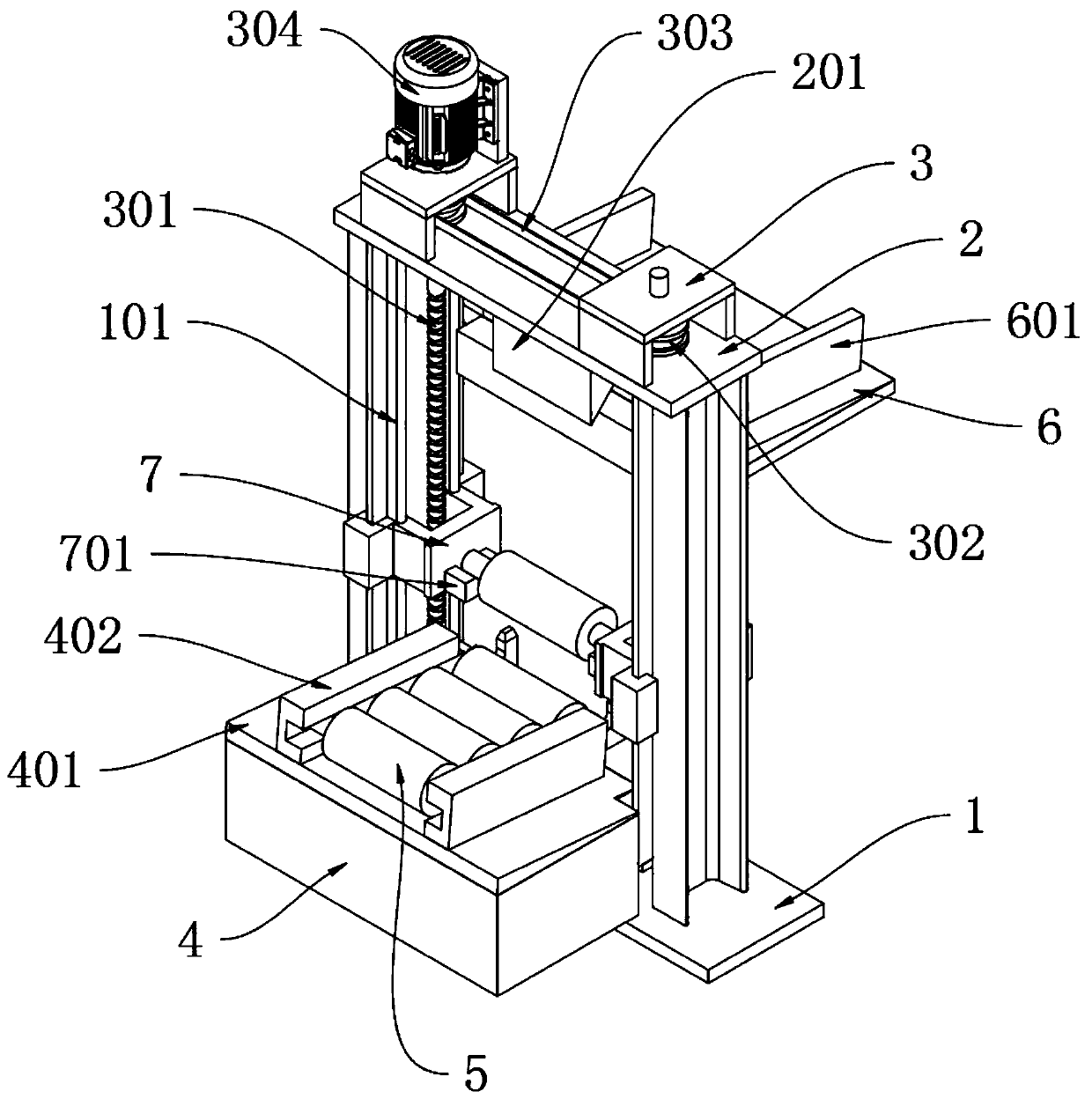

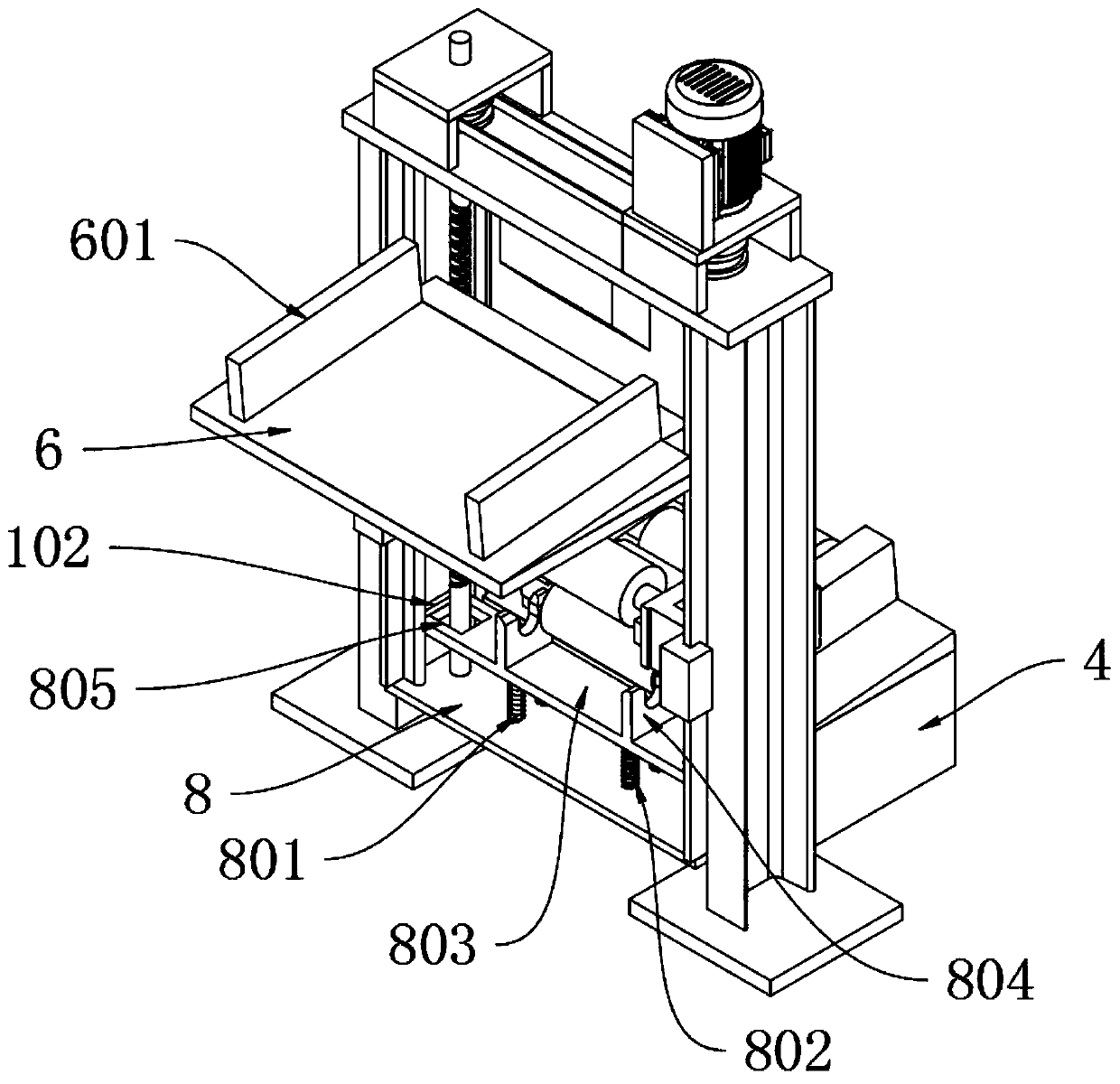

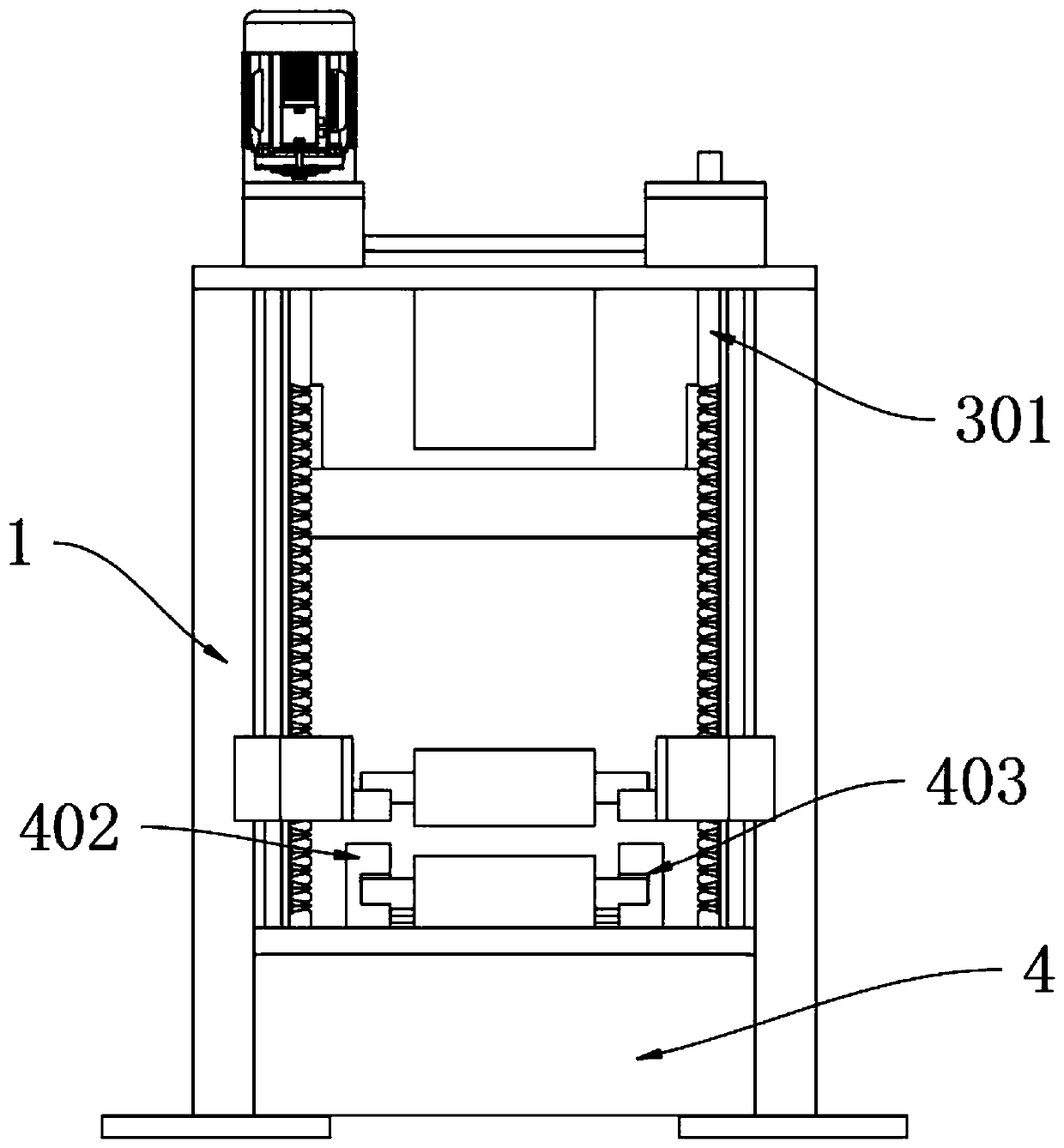

[0037] as attached figure 1 To attach Figure 8 Shown:

[0038] The present invention provides an intermittent automatic lifting transfer device for mechanical processing of roller shafts, including a lifting frame 1; the lifting frame 1 is composed of two vertical frames, and the upper ends of the two lifting frames 1 are horizontally fixed and installed The top supporting platform 2; the left end and the right end of the top supporting platform 2 are positioned at the position inside the lifting frame 1, and a rotating mechanism 3 is vertically rotated respectively, and the lower end of the rotating mechanism 3 is installed on the bottom plate of the lifting frame 1 through the rotation of the bearing ring;

[0039] The relative lifting mechanisms 7 are vertically slidably installed on the opposite side walls of the inner sides of the two lifting frames 1, and the inner ends of the lifting mechanisms 7 are engaged with the rotating mechanism 3; There is a blocking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com