Sewage treatment plant sludge treatment method, organic fertilizer and preparation method of organic fertilizer

A technology of sewage treatment plant and treatment method, which is applied in the direction of sewage/sludge fertilizer, organic fertilizer, biological sludge treatment, etc., which can solve the problems of waste of resources, increase of sludge treatment costs, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

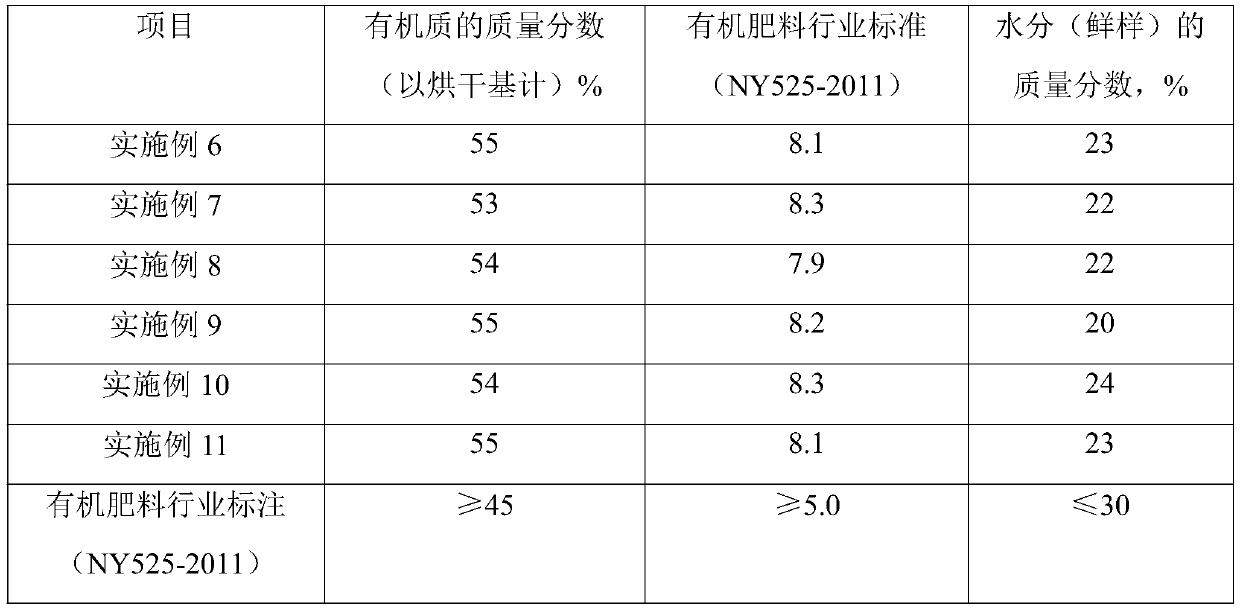

Examples

Embodiment 1

[0043] A treatment method for sludge from a sewage treatment plant, comprising the following steps:

[0044] S1. Pour 15 parts of edible fungus residue into a fermentation container and ferment at 20°C for 45 days;

[0045] S2. Take out the fermented edible fungus residue and add it to 35 parts of sludge, add 0.1 part of microbial deodorant, stir evenly, pour the material into a fermentation container, and ferment at 20°C for 15 days;

[0046] S3. Add 3 parts of tobacco into the fermentation container and stir evenly to complete the sludge treatment of the sewage treatment plant.

Embodiment 2

[0048] A treatment method for sludge from a sewage treatment plant, comprising the following steps:

[0049] S1. Pour 20 parts of edible fungus residue into a fermentation container and ferment at 20°C for 45 days;

[0050] S2. Take out the fermented edible fungus residue and add it to 40 parts of sludge, add 0.2 part of microbial deodorant, stir evenly, pour the material into a fermentation container, and ferment at 20°C for 15 days;

[0051] S3. Add 4.5 parts of tobacco into the fermentation container and stir evenly to complete the sludge treatment of the sewage treatment plant.

Embodiment 3

[0053] A treatment method for sludge from a sewage treatment plant, comprising the following steps:

[0054] S1. Pour 25 parts of edible fungus residue into a fermentation container and ferment at 20°C for 45 days;

[0055] S2. Take out the fermented edible fungus residue and add it to 45 parts of sludge, add 0.3 part of microbial deodorant, stir evenly, pour the material into a fermentation container, and ferment at 20°C for 15 days;

[0056]S3. Add 6 parts of tobacco into the fermentation container and stir evenly to complete the treatment of sewage treatment plant sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com