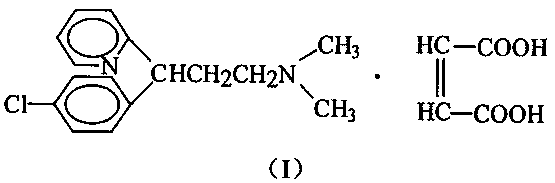

Chlorpheniramine maleate salifying substance and synthesis method and application thereof

The technology of a kind of chlorpheniramine acid and synthetic method is applied in the field of chlorpheniramine maleate salt formation to achieve the effects of improving purity and final yield, reducing impurity components, and reducing solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

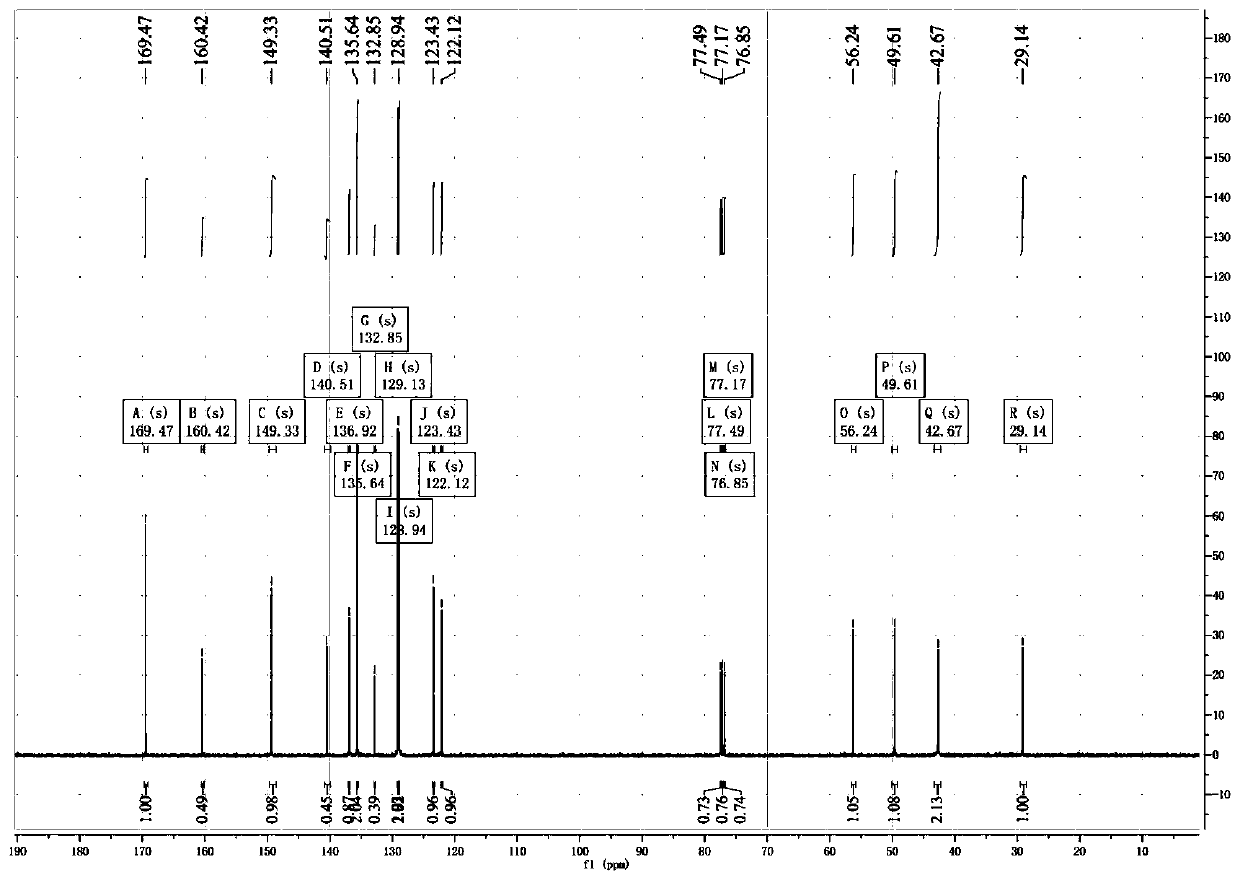

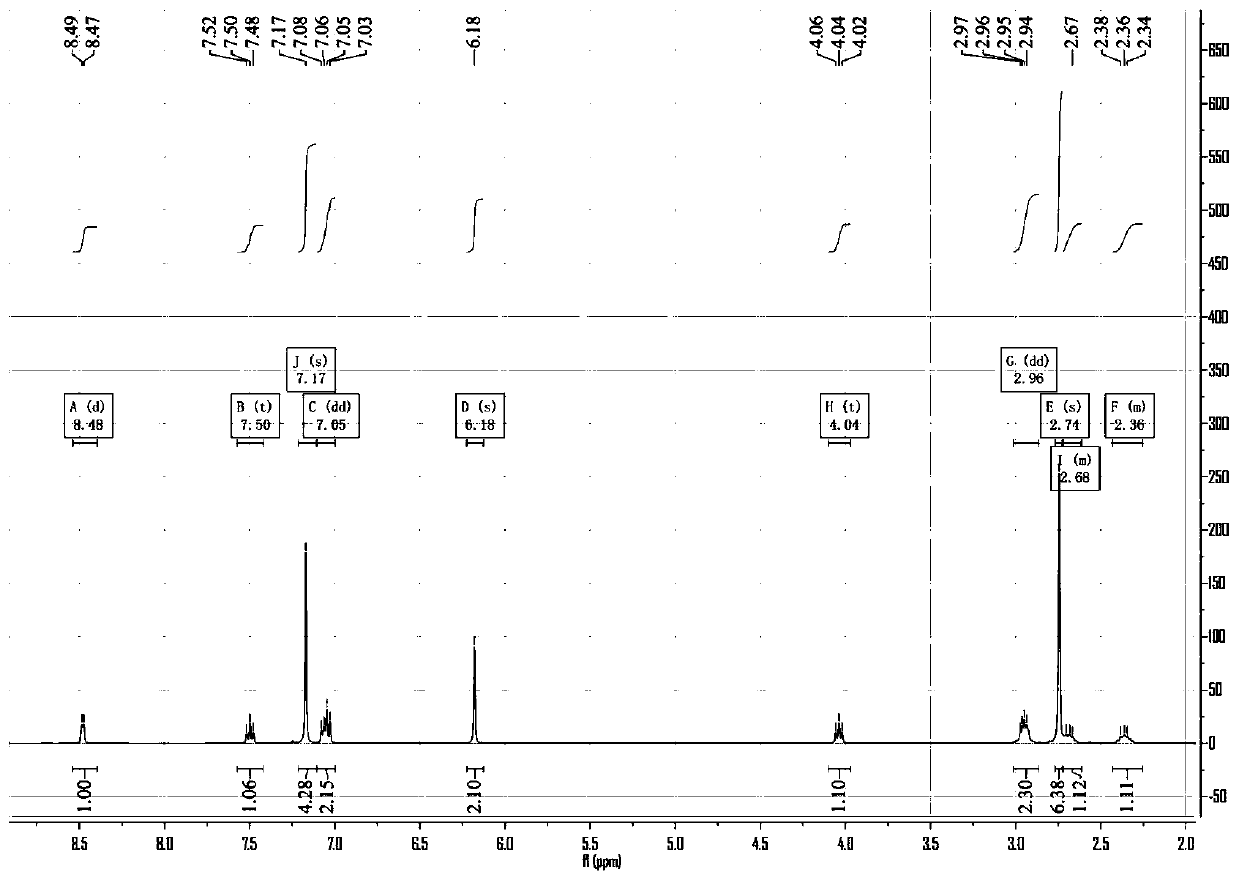

Image

Examples

Embodiment 1

[0032] Embodiment 1. A kind of preparation method of chlorpheniramine maleate salify

[0033] The present embodiment mainly describes a kind of preparation method of chlorpheniramine maleate, comprises the following steps:

[0034] Step 1. In the salt-forming kettle (1000L, glass-lined), weigh the raw material components: maleic acid 85kg, absolute ethanol 490kg, chlorpheniramine hydrolyzate 195kg and activated carbon 7kg; The raw material components are stirred, the stirring speed is 70 rpm, and the stirring time is 30 min to obtain a premix;

[0035] Step 2. Slowly heat the salt-forming kettle described in step 1 until reflux occurs at a heating rate of 2.5°C / min, and keep refluxing for 1 hour when heated to 80°C to obtain a heated feed liquid;

[0036] Step 3. Under heat preservation conditions, transfer the heated feed liquid obtained in Step 2 from the salt-forming kettle to a filter press (300L, stainless steel), and then press it from the filter press to the crystalliz...

Embodiment 2

[0044] Embodiment 2. A kind of preparation method of chlorpheniramine maleate salify

[0045] The present embodiment mainly describes a kind of preparation method of chlorpheniramine maleate salt, comprising the following steps:

[0046] Step 1. Add 190kg of chlorpheniramine hydrolyzate, 460kg of absolute ethanol, and then add 80kg of maleic acid and 4kg of activated carbon in a salt-forming kettle (1000L, glass-lined), and stir at a speed of 65 rpm , and the stirring time was 40 min to obtain a premix;

[0047] Step 2. Slowly heat the salt-forming kettle described in step 1 until reflux occurs at a heating rate of 1°C / min, and keep reflux at 75°C for 1.5 hours to obtain a heating feed liquid;

[0048] Step 3. Under the condition of heat preservation, transfer the heated feed liquid obtained in step 2 from the salt forming kettle to the filter press kettle (300L, stainless steel), and then use nitrogen to press from the filter press kettle to the crystallization kettle, and k...

Embodiment 3

[0055] Embodiment 3. A kind of preparation method of chlorpheniramine maleate salt

[0056] The present embodiment mainly describes a kind of preparation method of chlorpheniramine maleate salt, comprising the following steps:

[0057] Step 1. Add 210kg of chlorpheniramine hydrolyzate and 530kg of absolute ethanol to the salt-forming kettle (1000L, glass-lined), then add 90kg of maleic acid and 10kg of activated carbon for stirring at a stirring speed of 90 rpm , and the stirring time was 20 min to obtain a premix;

[0058] Step 2. Slowly heat the salt-forming kettle described in step 1 until reflux occurs, the heating rate is 5°C / min, and keep reflux at 85°C for 0.8 hours to obtain the heating feed liquid;

[0059] Step 3. Under heat preservation conditions, transfer the heated feed liquid obtained in Step 2 from the salt-forming kettle to a filter press (300L, stainless steel), and then press from the filter press to the crystallization kettle), and keep the nitrogen pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com