Reinforced polypropylene material and preparation method thereof

A polypropylene material and polypropylene technology, applied in the field of reinforced polypropylene material and its preparation, can solve the problems of poor low-temperature toughness, poor light aging resistance and heat aging performance, and inability to use for a long time, and achieve low-temperature toughness and long-term weather resistance Improve and meet the effect of long-term use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

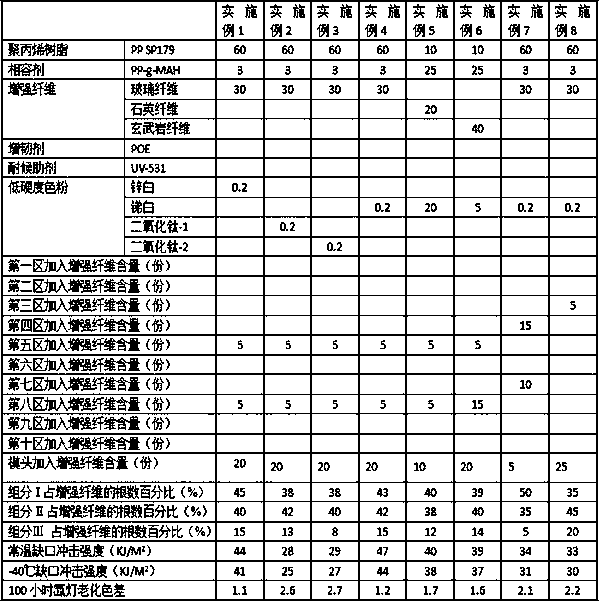

Embodiment 1-8 and comparative example 1-6

[0052] Examples 1-8 and Comparative Examples 1-6: Preparation of reinforced polypropylene materials

[0053] Weigh each component according to the formula content, and mix all components except the reinforcing fiber evenly, then add the mixture to the main feeding system of the twin-screw extruder; at the same time, add the reinforcing fiber to the side feeding of the twin-screw extruder material system, and then through twin-screw extruder melt blending, extrusion granulation to prepare reinforced polypropylene material.

[0054] The position of the side feeding system of the extruder can be adjusted, and the reinforcing fiber can enter the extruder screw in the first to tenth zones, and can be added after the extruder die, and then directly combined with the polypropylene melt.

[0055] Among them, the temperature of the first to second zones of the extruder is 120°C-160°C, the temperature of the third to fifth zones is 180°C-300°C, the temperature of the fifth to tenth zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com