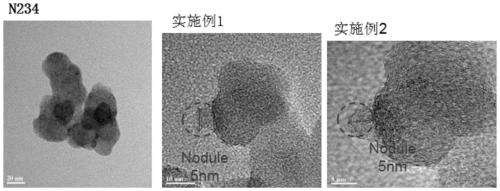

Low-hysteresis carbon black and production method thereof

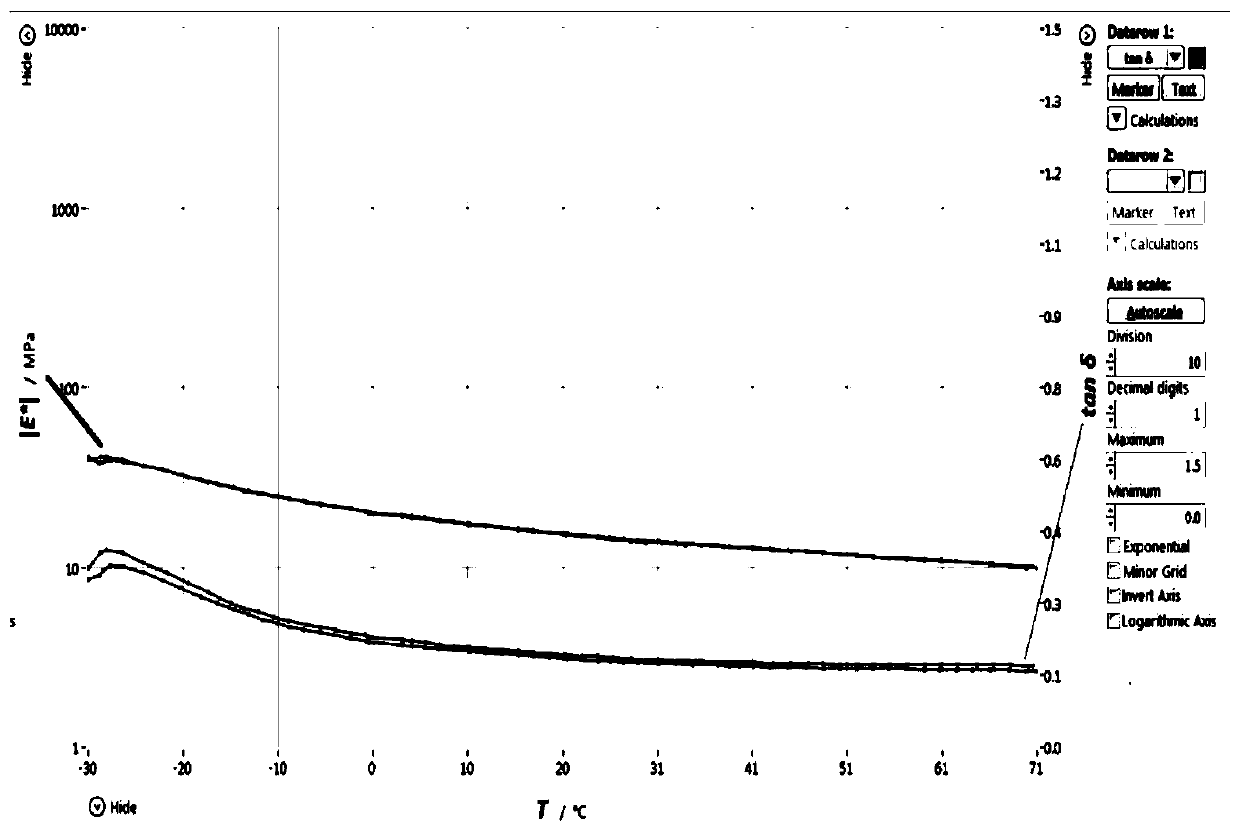

A lagging carbon black and carbon black technology, applied in the field of carbon black and its preparation, can solve the problems of carbon black wear resistance and low fuel consumption, and achieve the effects of good processing performance, low rolling resistance, and lower mixing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Examples and comparative examples are given only to further illustrate the present invention, and the present invention is not limited to the following examples.

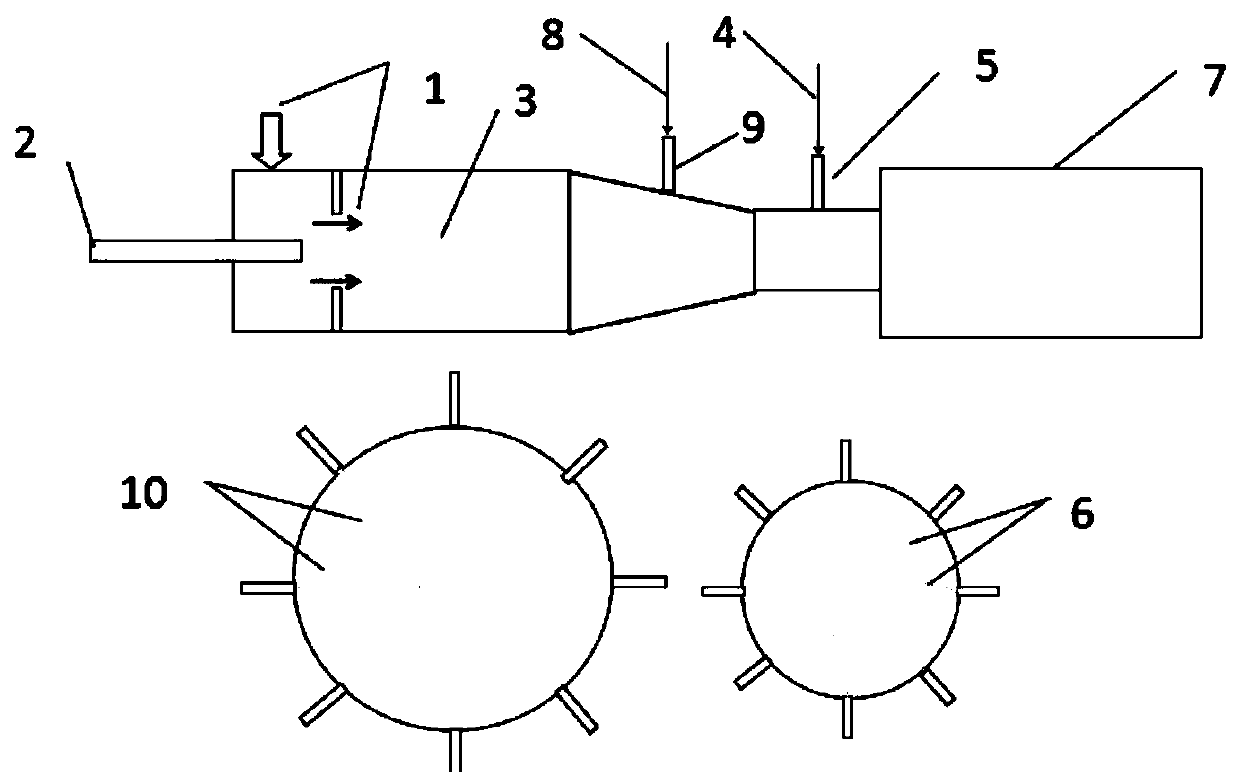

[0029] The low hysteresis carbon black of the present invention can be prepared by using a carbon black reaction furnace. The carbon black reaction furnace is a common equipment in the prior art. It generally includes a combustion section, a throat section, a reaction section and a quenching section; wherein the throat section is provided with a raw material oil spray system (main raw material oil spray system), which can be used to spray into The main raw material oil. In order to inject auxiliary raw material oil, an auxiliary raw material oil spray system is added at the rear of the combustion section in front of the main raw material oil spray system.

[0030] Such as figure 2 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com