Temperature-responsive self-lubricating hydrogel profile control agent and preparation method thereof

A hydrogel profile control agent and temperature-responsive technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor deep profile control effect and low water flooding wave efficiency, and achieve strong temperature resistance , The preparation method is simple, the effect of high plugging strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

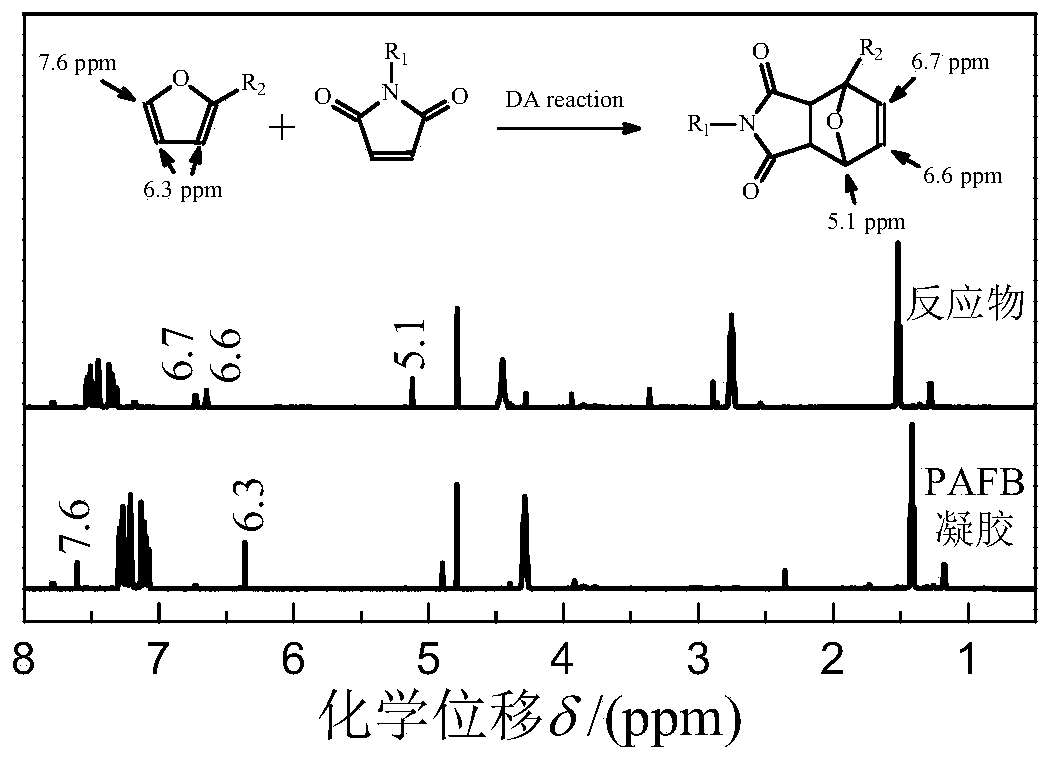

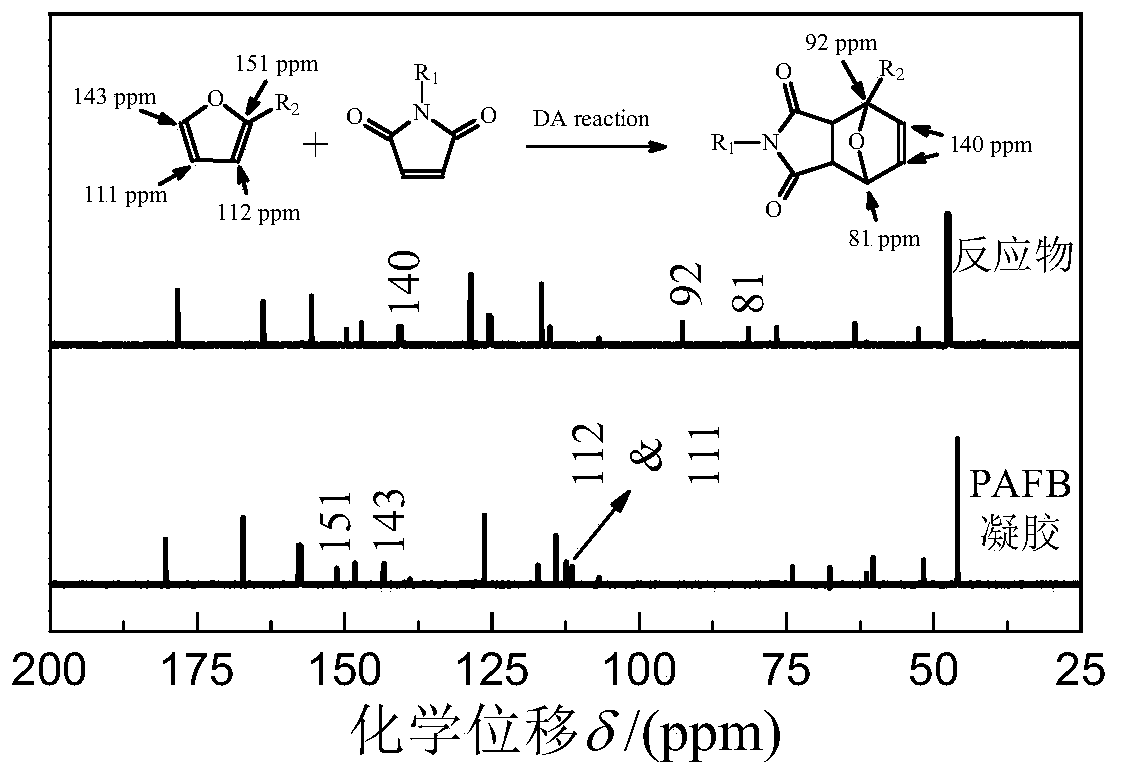

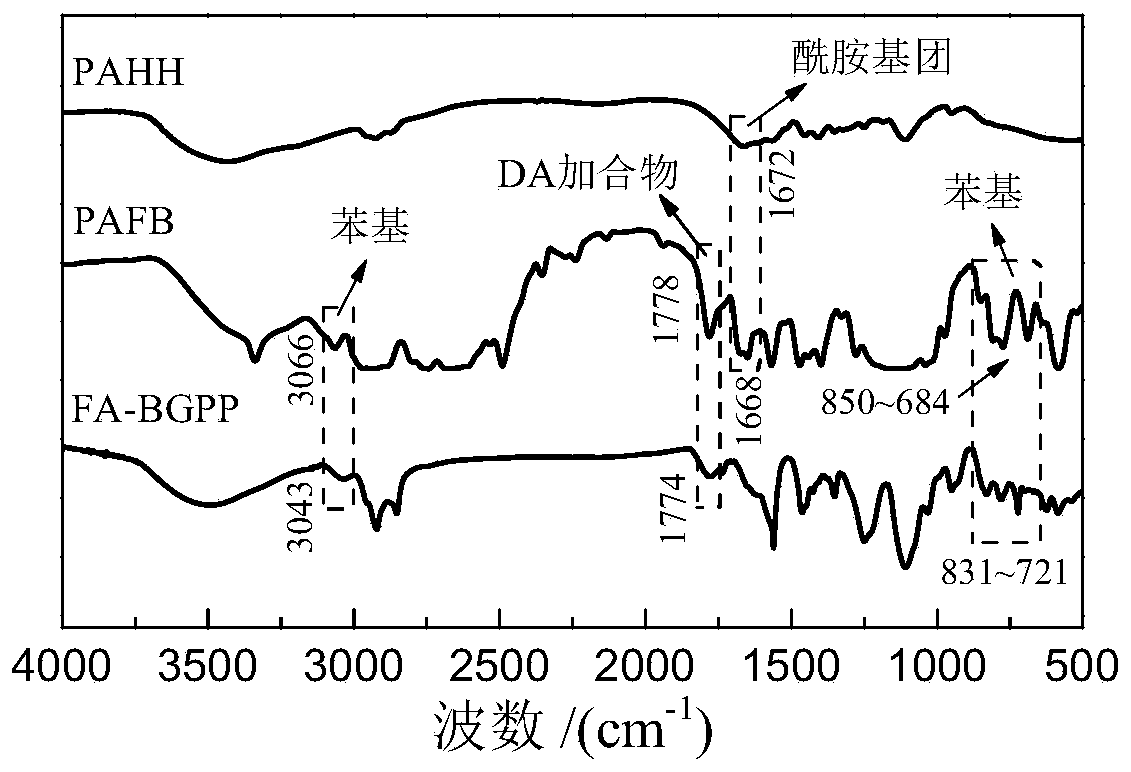

[0052] The experimental steps for the preparation of temperature-responsive self-lubricating hydrogel profile control agent are as follows:

[0053] (1) At 70°C±10°C, 0.3g polyacrylamide (PAM, Shanghai Macklin Biochemical Technology Co., Ltd.), 0.5g furfurylamine-bisphenol A diglycidyl ether oligomer (FA-BGPP, self-made) , 0.1g hexamethylenetetramine-hydroquinone crosslinking agent (HMTA-HQ, self-made) and 0.01g N,N'-(4,4'-methylenediphenyl)bismaleimide Amine (BM, Shanghai Macklin Biochemical Technology Co., Ltd.) was added into 100 mL of water and stirred to dissolve to obtain a reaction liquid.

[0054] (2) Stir the reaction solution at a stirring rate of 500rpm until the polymer in it swells evenly to obtain a sol, and then seal the sol and place it in an oven at 70°C±10°C for 48 hours to obtain a temperature-responsive self-lubricating Hydrogel profile control agent PAFB-1.

Embodiment 2

[0056] The experimental steps for the preparation of temperature-responsive self-lubricating hydrogel profile control agent are as follows:

[0057] (1) At 70°C±10°C, 0.5g polyacrylamide (PAM, Shanghai Macklin Biochemical Technology Co., Ltd.), 0.7g furfurylamine-bisphenol A diglycidyl ether oligomer (FA-BGPP, self-made) , 0.3g hexamethylenetetramine-hydroquinone (HMTA-HQ, homemade) and 0.03g N,N'-(4,4'-methylenediphenyl) bismaleimide (BM , Shanghai McLean Biochemical Technology Co., Ltd.) was added into 100 mL of water and stirred to dissolve to obtain a reaction solution.

[0058] (2) Stir the reaction solution at a stirring rate of 500rpm until the polymer in it swells evenly to obtain a sol, and then seal the sol and place it in an oven at 70°C±10°C for 48 hours to obtain a temperature-responsive self-lubricating Hydrogel profile control agent PAFB-2.

Embodiment 3

[0060] The experimental steps for the preparation of temperature-responsive self-lubricating hydrogel profile control agent are as follows:

[0061] (1) At 70°C±10°C, 0.7g polyacrylamide (PAM, Shanghai Macklin Biochemical Technology Co., Ltd.), 0.9g furfurylamine-bisphenol A diglycidyl ether oligomer (FA-BGPP, self-made) , 0.5g hexamethylenetetramine-hydroquinone (HMTA-HQ, homemade) and 0.05g N,N'-(4,4'-methylenediphenyl)bismaleimide (BM , Shanghai McLean Biochemical Technology Co., Ltd.) was added into 100 mL of water and stirred to dissolve to obtain a reaction solution.

[0062] (2) Stir the reaction solution at a stirring rate of 500rpm until the polymer in it swells evenly to obtain a sol, and then seal the sol and place it in an oven at 70°C±10°C for 48 hours to obtain a temperature-responsive self-lubricating Hydrogel profile control agent PAFB-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com