Layered grouting freezing device and layered grouting freezing method

A technology of freezing device and grouting, which is applied in basic structure engineering, construction, soil protection, etc. It can solve the problems that the grouting position is not targeted and affects the effect of soil reinforcement and groundwater layer water-stopping, etc., and achieves the convenience of transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

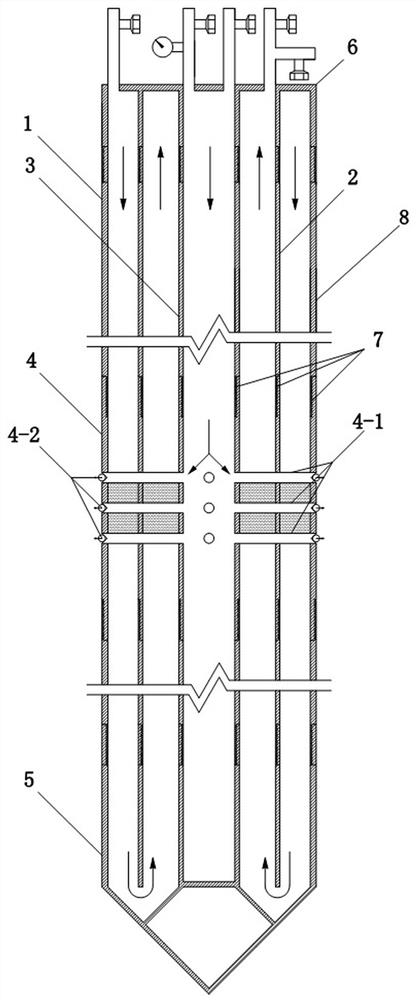

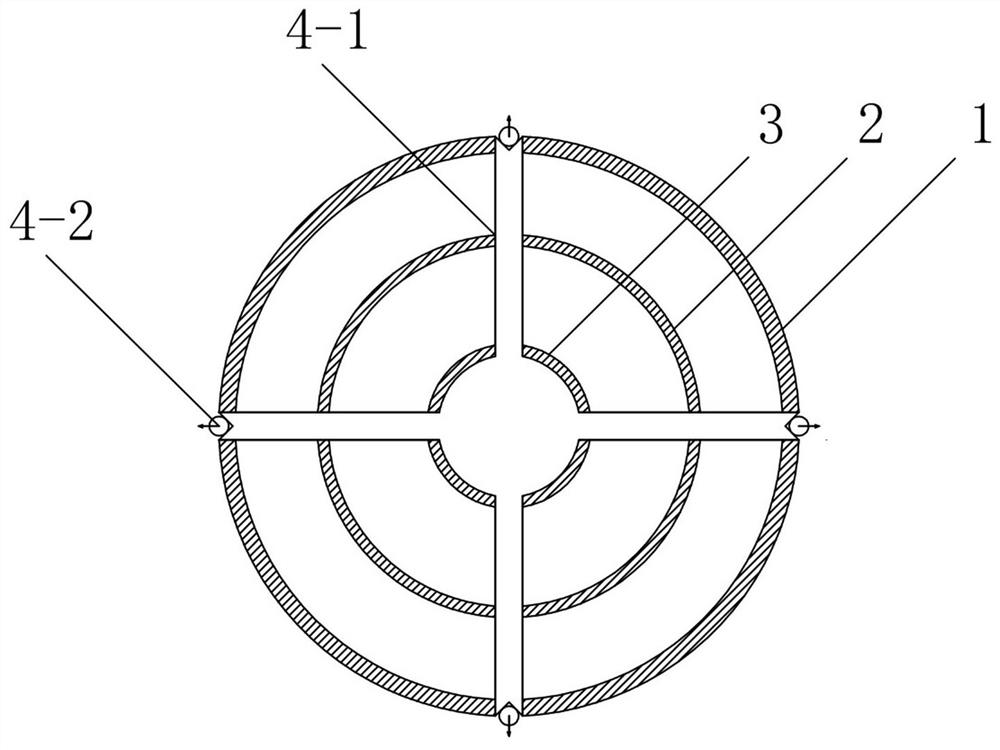

[0055] Such as figure 1 As shown, the layered grouting freezing device includes a layered grouting pipeline, and the layered grouting pipeline includes a liquid return pipe 2, a grouting pipe 3 and a freezing pipe 1, and the grouting pipe 3, the liquid returning pipe 2 and the freezing pipe 1 are from They are arranged sequentially from inside to outside to form concentric cylinders, and the bottom of the grouting pipe 3 is closed. Such as Figure 4 As shown, the bottom of the layered grouting pipeline is provided with a drill bit 5, and the drill bit 5 is arranged on the bottom of the layered grouting pipeline through a threaded connection. The drill bit 5 has a return cavity 5-1, and the return pipe 2 and the freezing pipe 1 are all Connected with the return chamber 5-1, the freezing pipe 1, the return chamber 5-1 and the liquid return pipe 2 form a low-temperature freezing liquid flow channel.

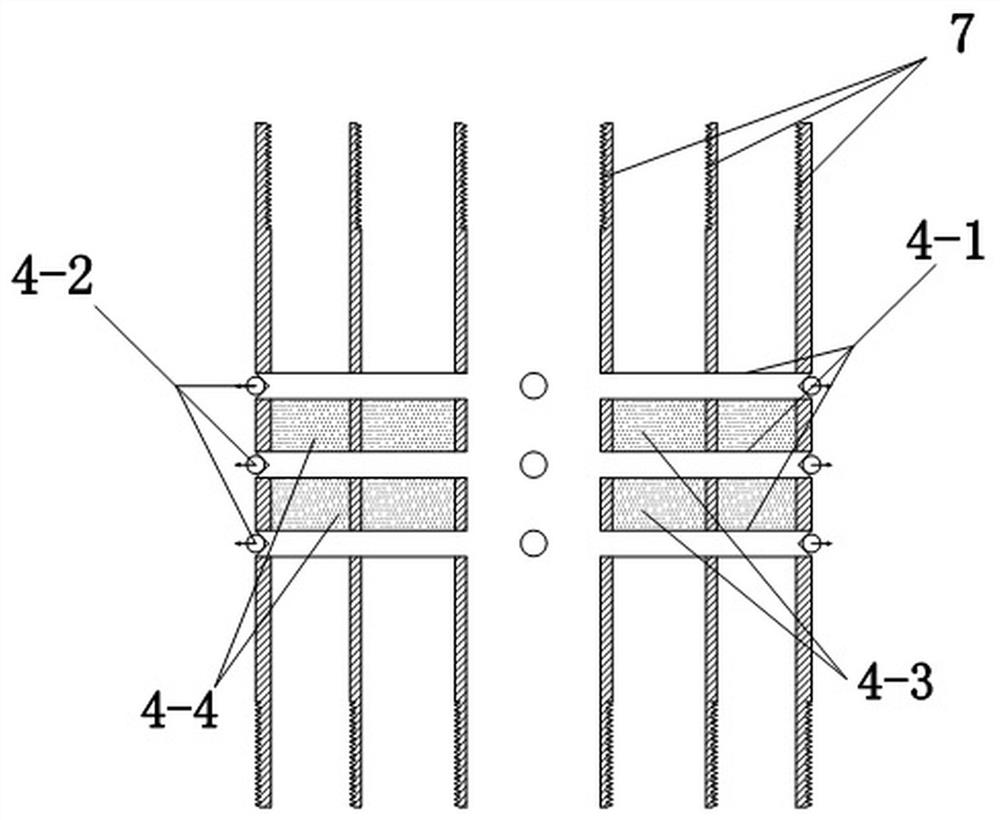

[0056] Such as figure 2 with image 3 As shown, the layered grouting pipel...

specific Embodiment 2

[0066] Specific embodiment 2 of the layered grouting freezing device of the present invention: The difference between this embodiment and specific embodiment 1 is that in specific embodiment 1, the layered grouting pipe grouting pipeline adopts the first pipeline monomer and the second The form of arrangement and combination of pipeline monomers. In this embodiment, the layered grouting pipe grouting pipeline does not include the first pipeline monomer, and is formed by connecting the second pipeline monomers in sequence. At this time, the injection of the layered grouting freezing device The performance of slurry reinforcement is better, but the amount of slurry used is larger.

specific Embodiment 3

[0067] Specific embodiment 3 of the layered grouting freezing device of the present invention: The difference between this embodiment and specific embodiment 1 is that, in specific embodiment 1, the layered grouting pipes and the grouting pipes are sequentially grouting pipes from inside to outside , liquid return pipe and freezing pipe, and the grouting pipe, liquid return pipe and freezing pipe constitute concentric cylinders. In this embodiment, the grouting pipe, liquid returning pipe and freezing pipe form concentric cylinders, but the grouting pipe Between the liquid tube and the freezing tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com