Preheating system of magnetic material sintering furnace

A technology of magnetic materials and sintering furnaces, which is applied in the direction of preheating costs, lighting and heating equipment, furnaces, etc., can solve problems such as waste of heat energy resources, and achieve the effects of energy saving, temperature balance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

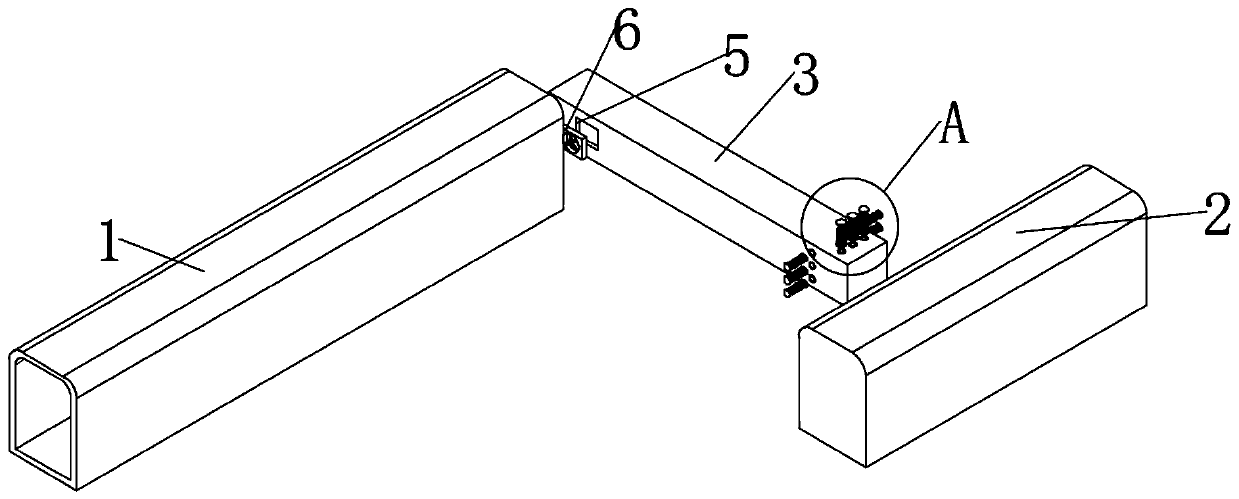

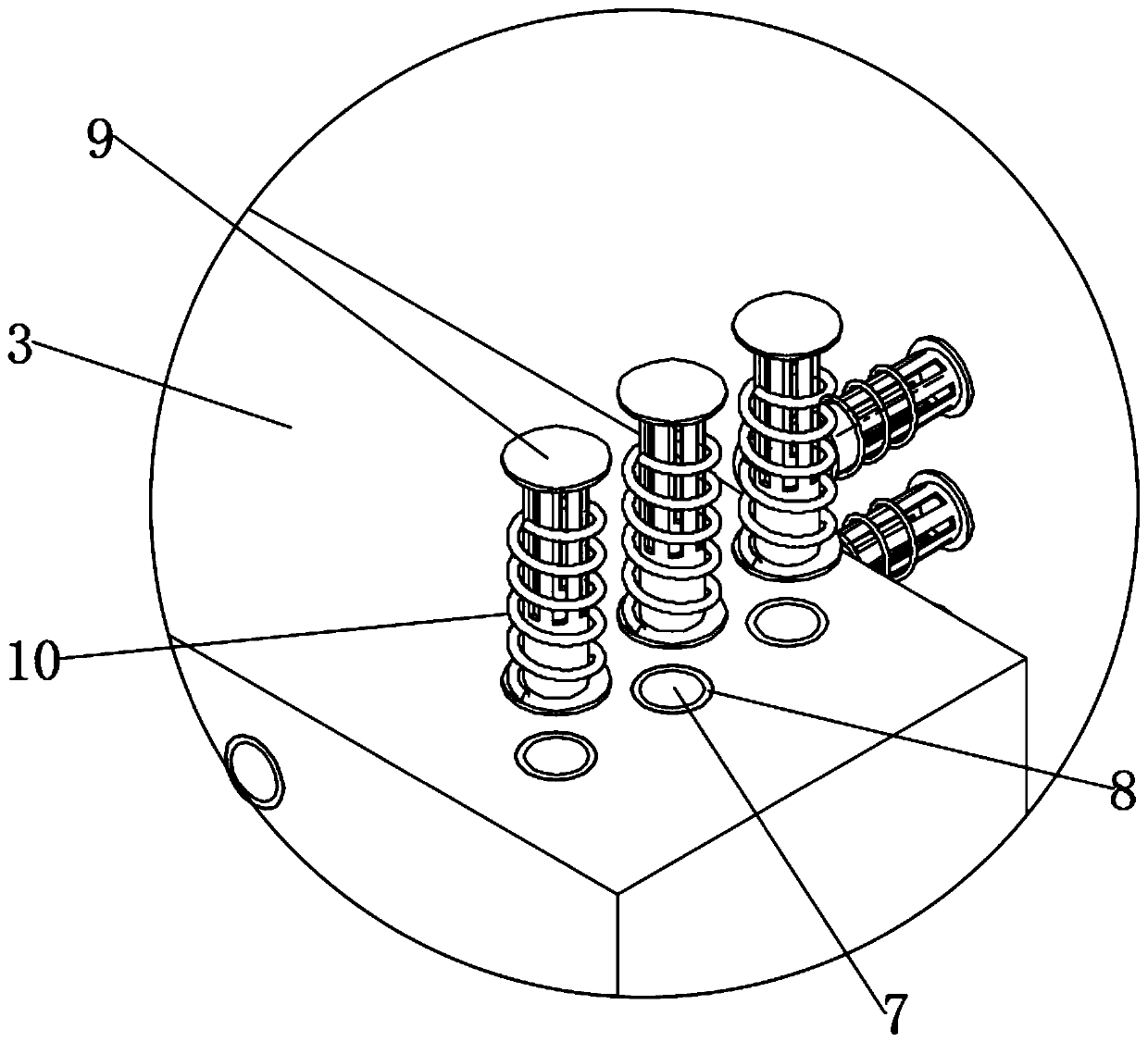

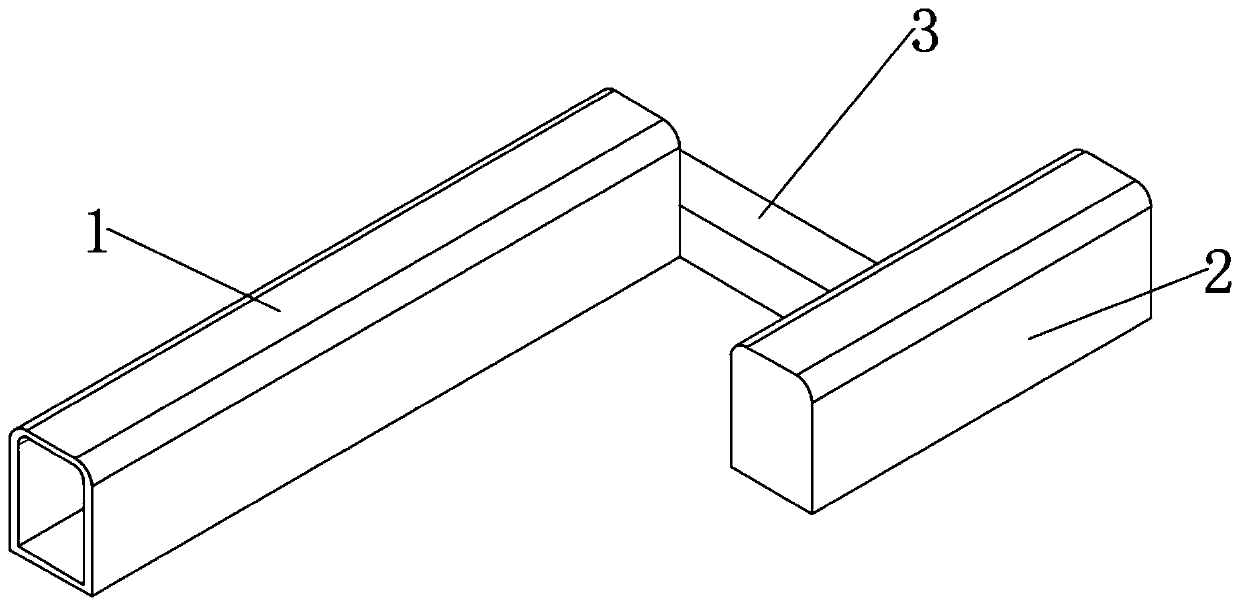

[0035] see Figure 1-8, magnetic material sintering furnace preheating system, including sintering kiln 1 and heating bin 2, sintering kiln 1 is located in the inner rail area of the sintering kiln, heating bin 2 is located in the outer rail area of the sintering kiln, and the length of 2 is 6 There is a connecting channel 3 fixedly connected between the sintering kiln 1 and the heating chamber 2, a through hole 4 is dug on the side wall of the sintering kiln 1, and a fan installation groove 5 matching the through hole 4 is dug in the connecting channel 3 , the sintering kiln 1 and the heating chamber 2 are connected through the connecting channel 3 and the through hole 4, the through hole 4 is fixedly connected with an exhaust fan 6 matching itself, and the end of the connecting channel 3 close to the heating chamber 2 runs through the heating chamber The side wall of 2 extends to the inside of the heating chamber 2, and a plurality of heat dissipation holes 7 are dug on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com