Non-uniform radiant heat environment test bed and using method thereof

An environmental test and radiant heat technology, applied in the testing, measuring devices, instruments, etc. of machines/structural components, can solve the problems of complex, unreachable, and inconvenient production and installation processes, saving production time and costs, The effect of flexible and variable floor space, easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

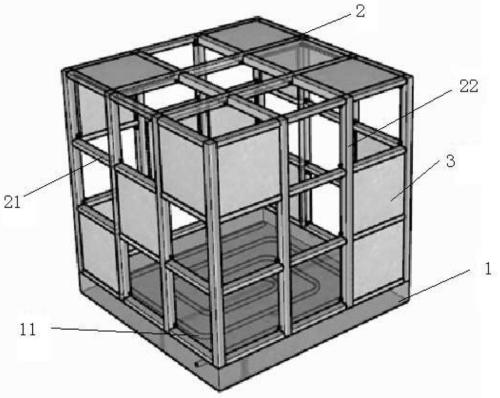

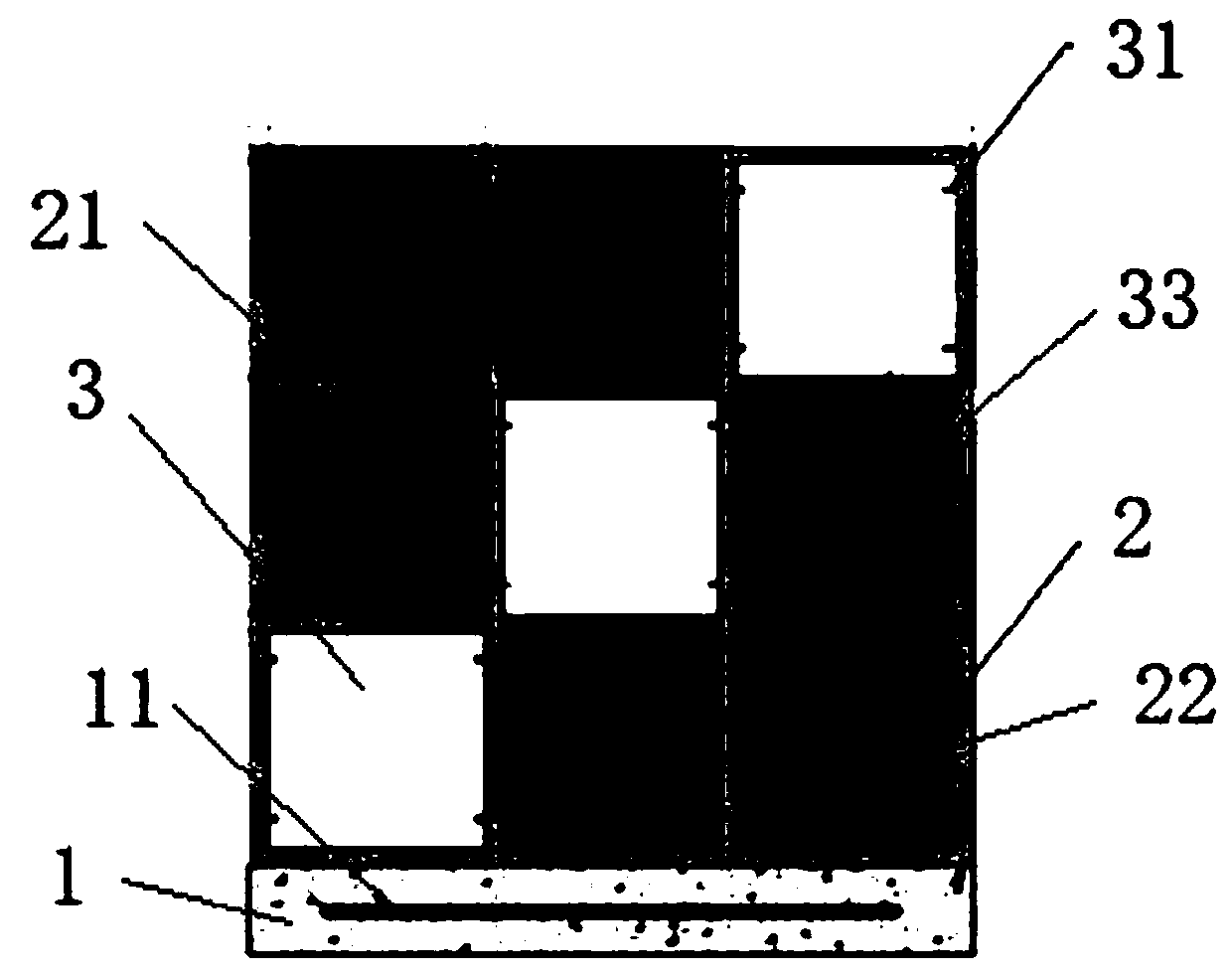

[0042] Embodiment 1, a kind of non-uniform radiant heat environment test bench, such as Figure 1 to Figure 6 Said, comprising a concrete module base 1 and frame 2.

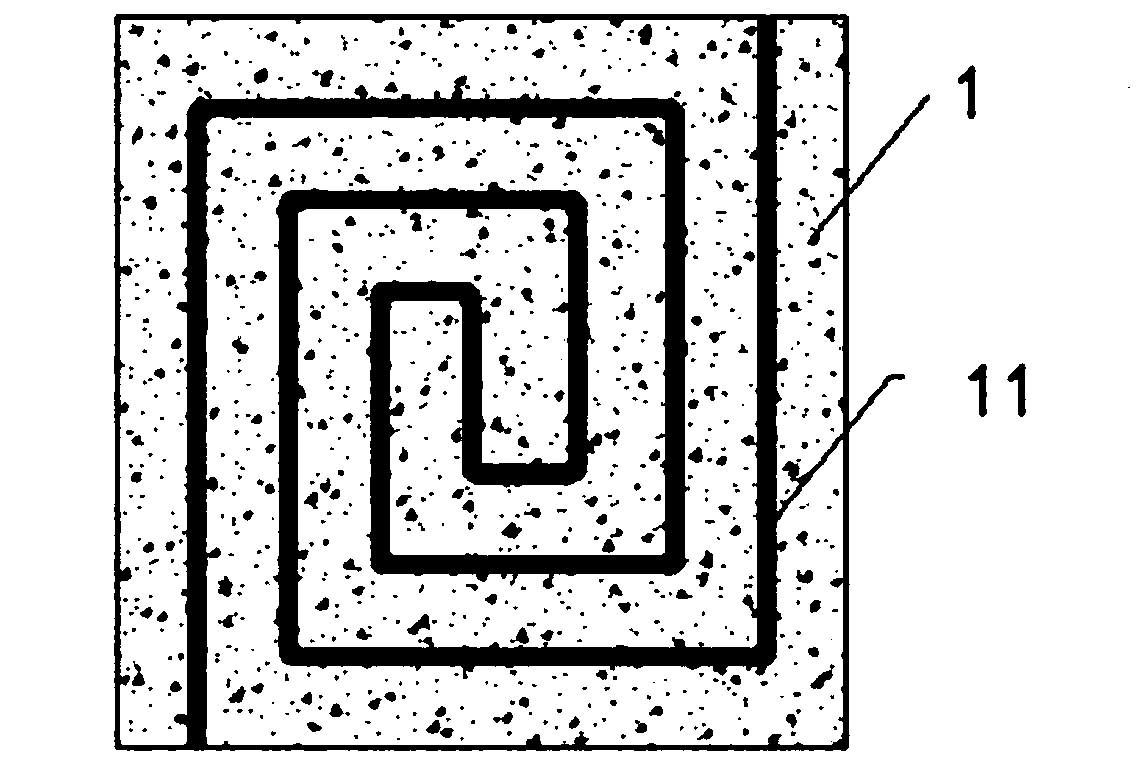

[0043] The horizontal cross-section of the concrete module base 1 is a square, such as figure 2 As shown, a looped coil pipe 11 is buried along the horizontal plane inside it, and the coil pipe 11 is, for example, a cross-linked polyethylene pipe; The temperature is used to simulate floor cooling and floor heating. In order to achieve good heat transfer, the thickness of the concrete module base 1 is generally 100mm-120mm.

[0044] The frame 2 is a cube-shaped frame (that is, only composed of 12 columns), such as figure 1 with image 3 As shown, the frame 2 can be made of heat-insulating materials and placed on the concrete module base 1, the bottom surface of the frame 2 coincides with the concrete module base 1 (that is, both have the same area size), the frame 2 and the concrete module The base 1 together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com