Integrated vertical transition power divider

A technology of power splitter and branch port, which is applied in the direction of waveguide devices, electrical components, connection devices, etc., can solve the problems of excessive circuit size and low isolation, and achieve compact structure, high withstand power, and small power attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

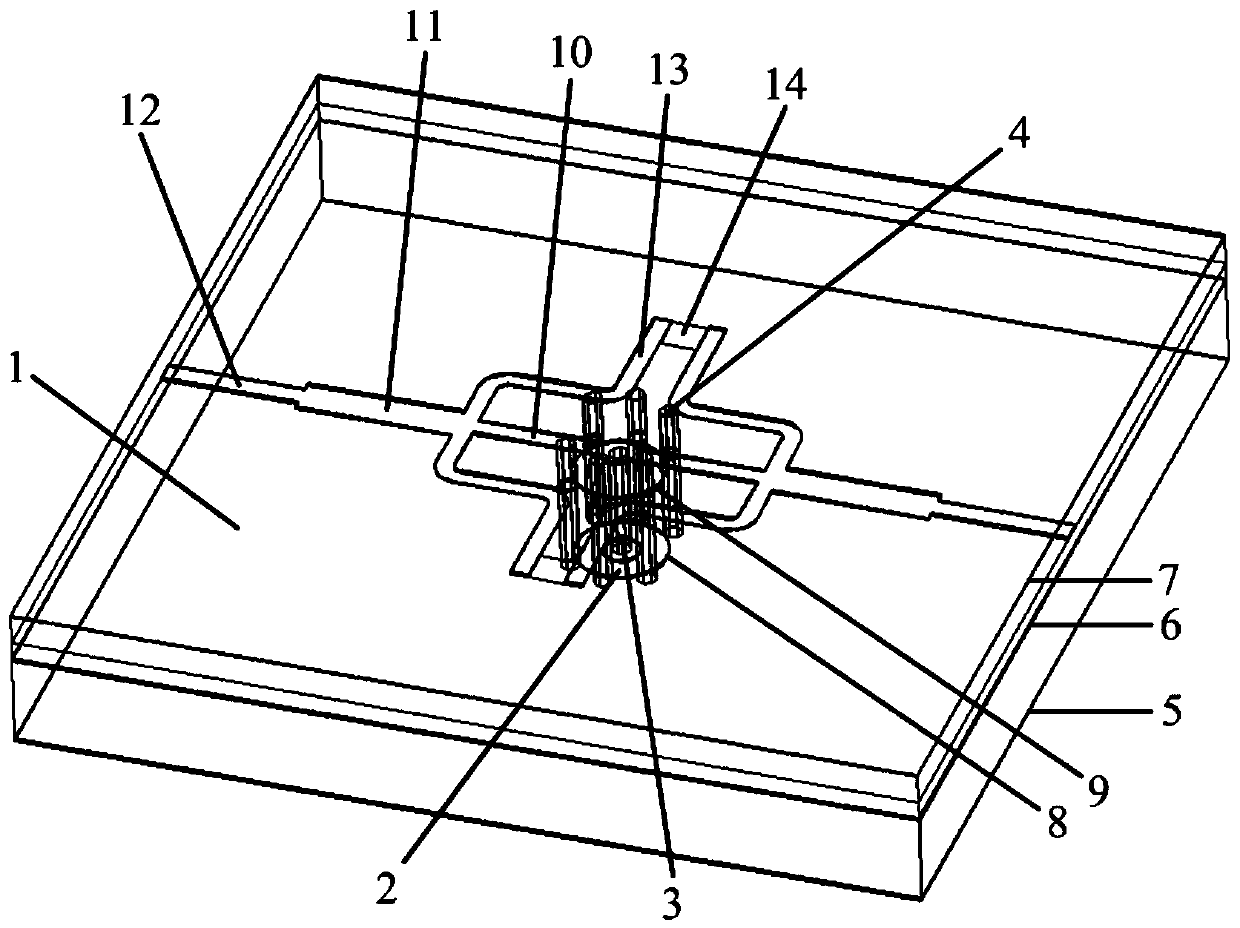

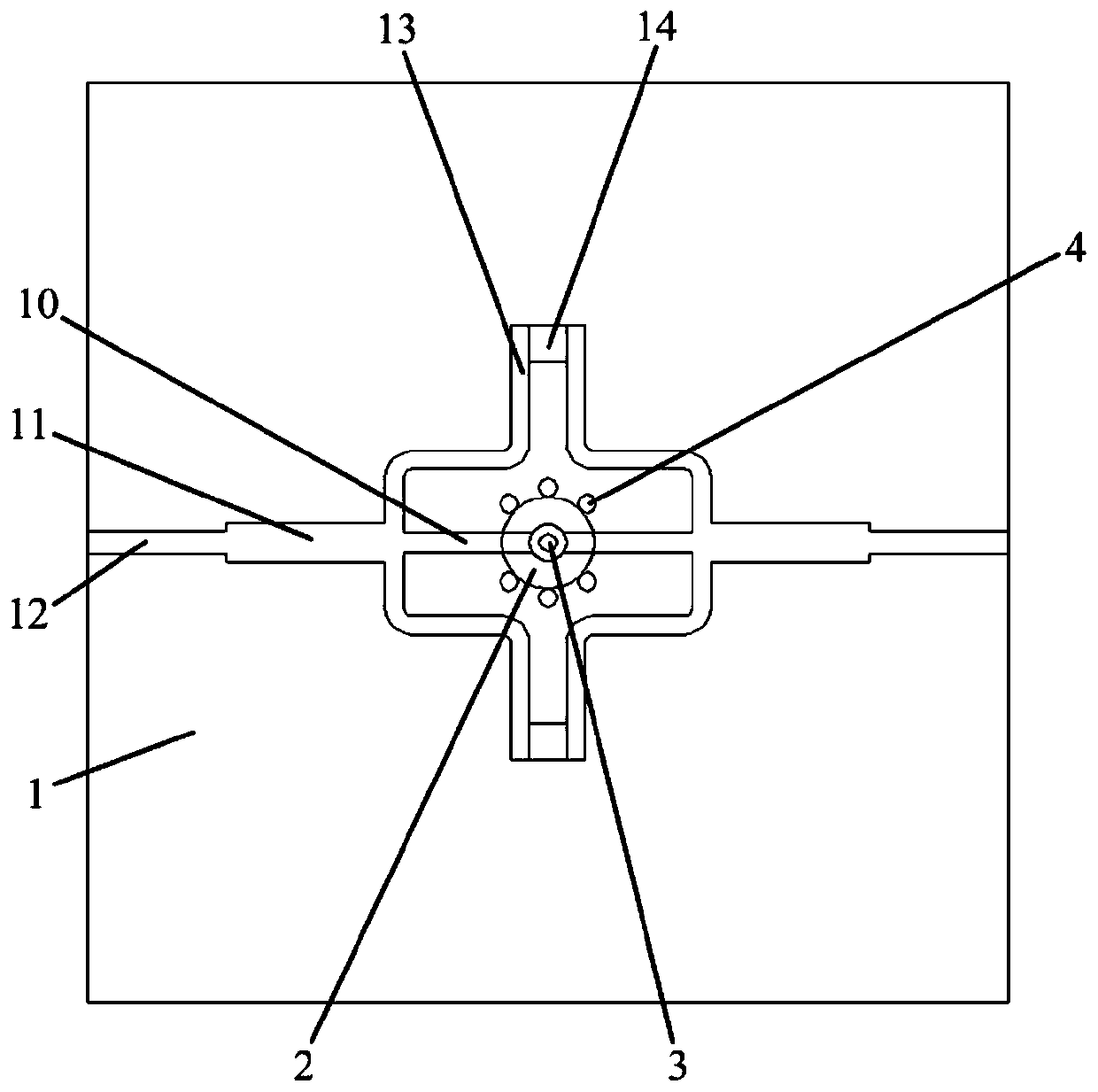

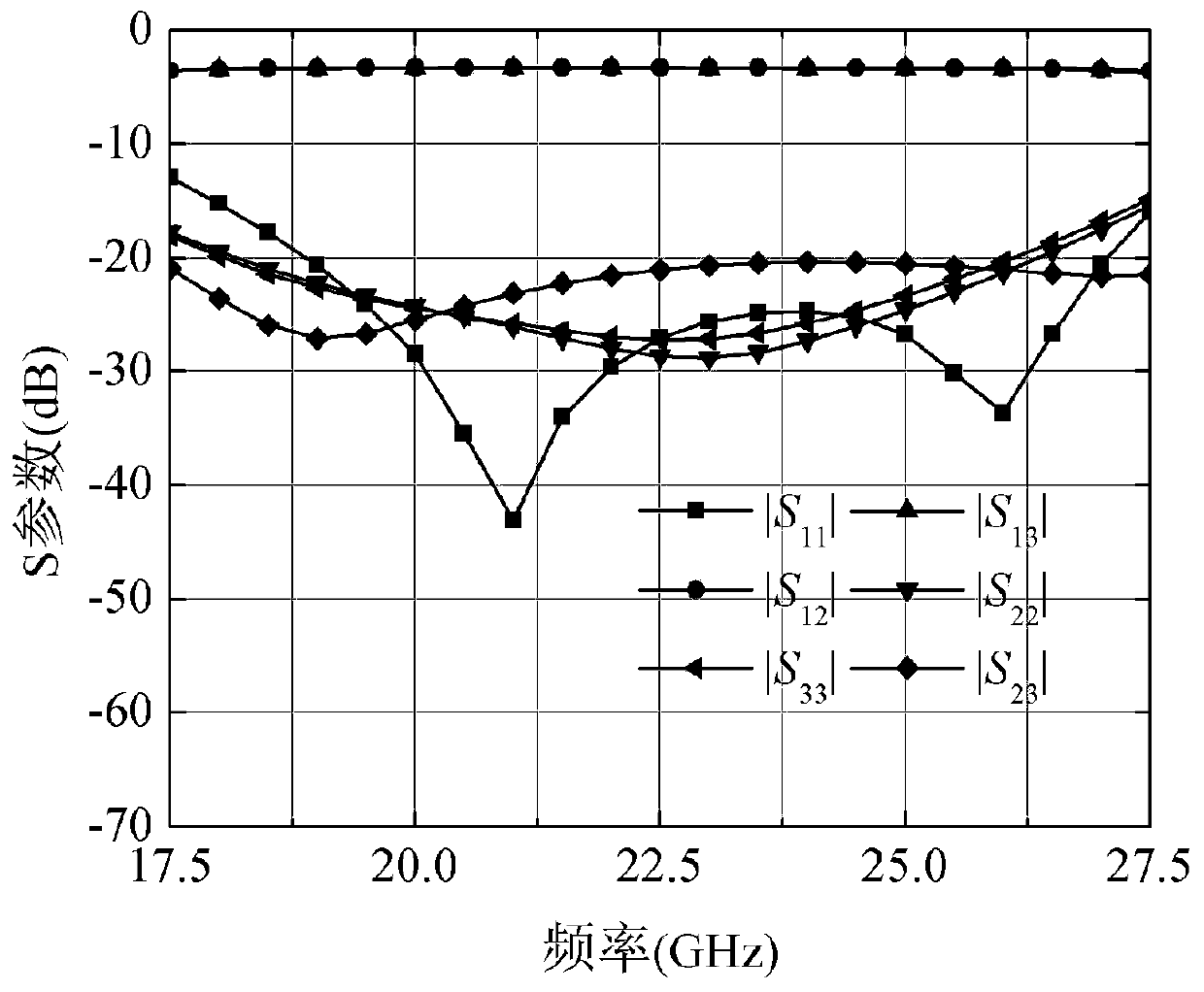

[0019] refer to figure 1 and figure 2 . A vertically integrated isolated transition power divider, comprising: lower surface ground 5, inner layer ground 6, upper surface ground 7, common port integrated coaxial 2 inserted into multilayer dielectric board 1, distributed and arranged around the common port integrated coaxial 2 The metallized via hole 4 is used to integrate the metallized via hole 4 at both ends of the coaxial 2 through the symmetrical common port. The two high-resistance matching striplines 10 between the layer ground 6 and the upper surface ground 7 are transitionally connected to two low-resistance matching striplines through two isolation striplines 13 that are symmetrically curved in the shape of a "ji" along the center. Stripline 11, two-way low-impedance matching stripline 11 respectively pass through two-way branch port stripline 12 back to the branch port of cascaded input and output ends, isolated stripline 13 isolates four-way coupled stripline of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com