Dust suppression system for calcium carbonate stock ground

A calcium carbonate and stockyard technology, applied in the direction of using liquid separation agent, separation device, membrane technology, etc., can solve the problems of dead angle of dust suppression, limited spray coverage, poor dust suppression effect, etc., and achieve the effect of expanding the scope of spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

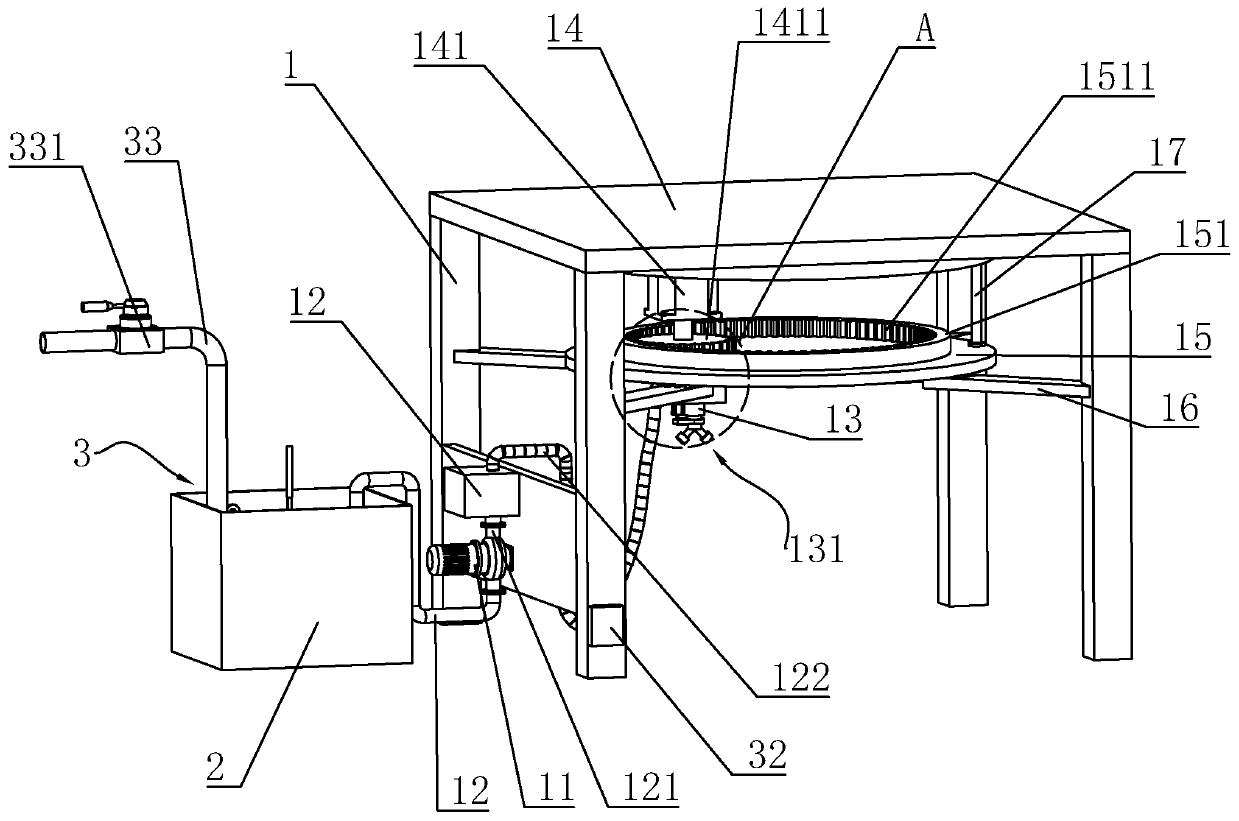

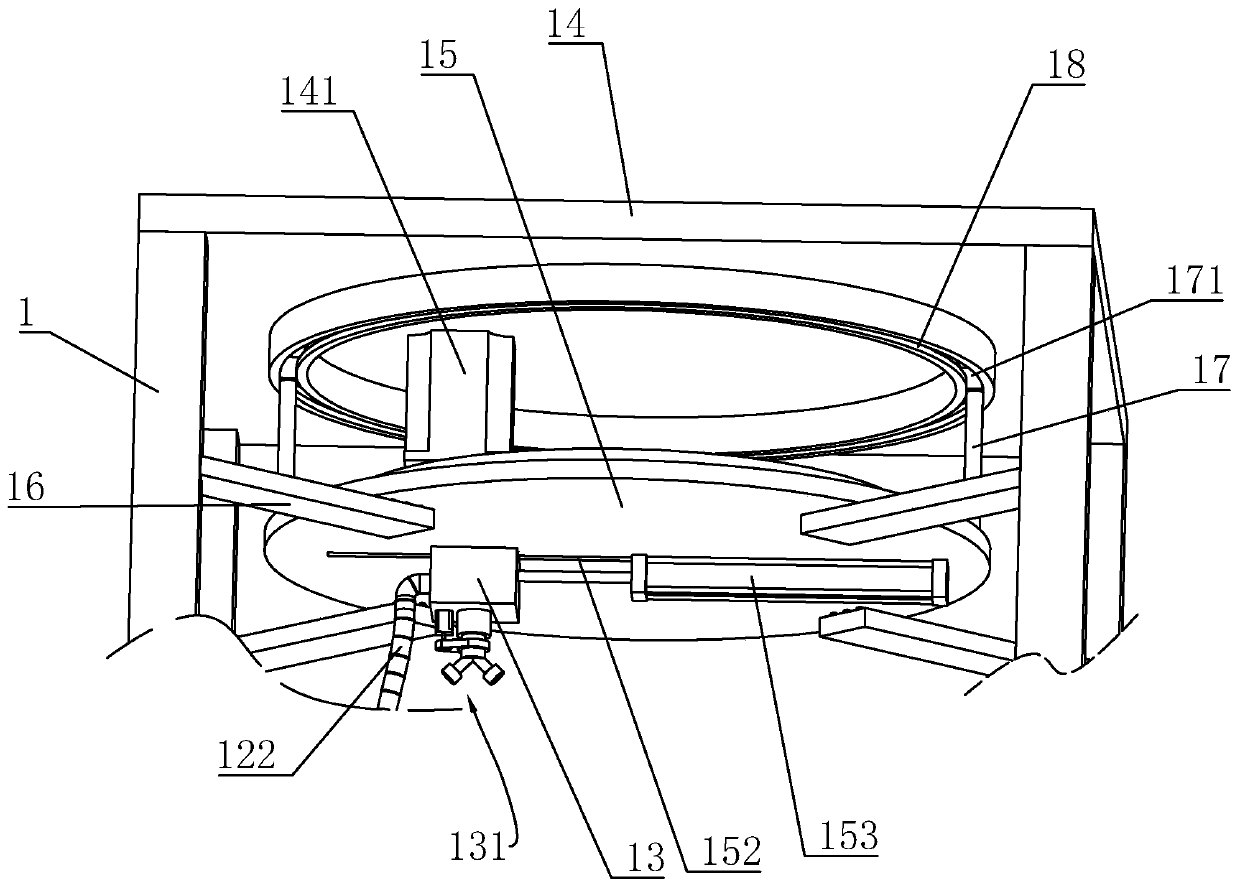

[0036] Example: refer to figure 1 , is a dust suppression system for a calcium carbonate stockyard disclosed by the present invention, comprising a support frame 1 and a water storage tank 2 arranged on one side of the support frame 1, and the support frame 1 is fixed with a water pump 11 and a micro mist Dust suppressor 12, water pump 11 and water storage tank 2 are provided with suction pipe 111, one end of water suction pipe 111 is connected to water pump 11, and the other end stretches into the bottom of water storage tank 2 inner cavity, water pump 11 and micro A water outlet pipe 121 is provided between the fog and dust suppressors 12, and the two ends of the water outlet pipe 121 are respectively connected with the water pump 11 and the micro mist dust suppressor 12.

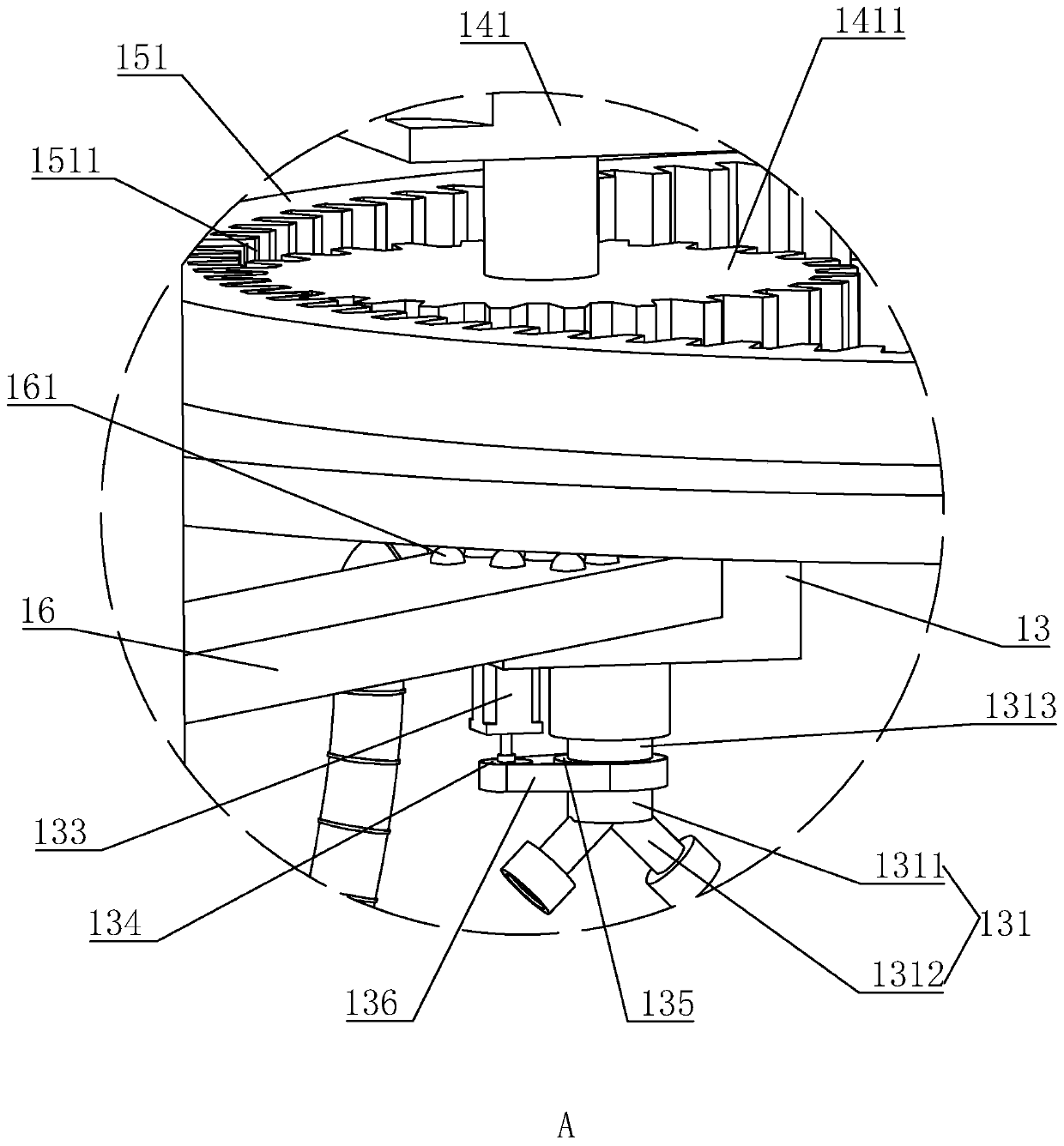

[0037] refer to figure 1 with figure 2 A top plate 14 is fixedly connected to the top of the support frame 1, and a first motor 141 is installed upside down on the side of the top plate 14 facing the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com