Recyclable Ru nano catalyst, preparation method thereof and application thereof in preparation of cis-pinane

A nano-catalyst and catalyst technology, applied in catalyst activation/preparation, catalyst, organic chemical methods and other directions, can solve the problems of easy agglomeration, separation and recovery, difficulty of nano-particle catalyst, and achieve high catalytic hydrogenation activity and cis-pinane selection. High stability, good stability, convenient separation and recovery and recyclable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

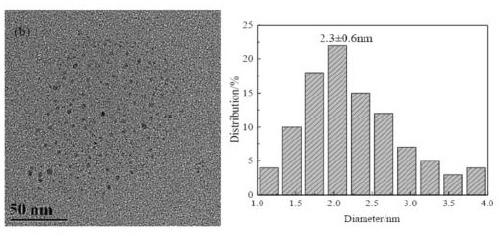

[0028] Weigh 0.01g RuCl 3 ·xH 2 O and 25g PEG6000 join in the stainless steel autoclave, the stainless steel autoclave is sealed, check for leaks, pass three times N 2 Displace the air in the unit. Heat to 90°C and maintain the temperature, and stir for 2h at a rotation speed of 500r / min. Use H again 2 The gas in the kettle of the gas replacement device was passed 3 times, and then 4MPa of H 2 Gas, reduced at the above stirring rate and temperature for 8h. Cooling Excludes H 2 , that is, PEG-stabilized Ru nanocatalysts were obtained. Its transmission electron microscope (TEM) figure 2 As shown, the average particle size is 2.3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com