A hydraulic control system with ultra-high precision and improved reaction conversion rate

A technology of reaction conversion rate and precision, applied in the field of precision instruments, can solve the problems of changing the inherent state of the solution, unable to effectively control the droplet size, etc., to achieve the effect of improving the reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

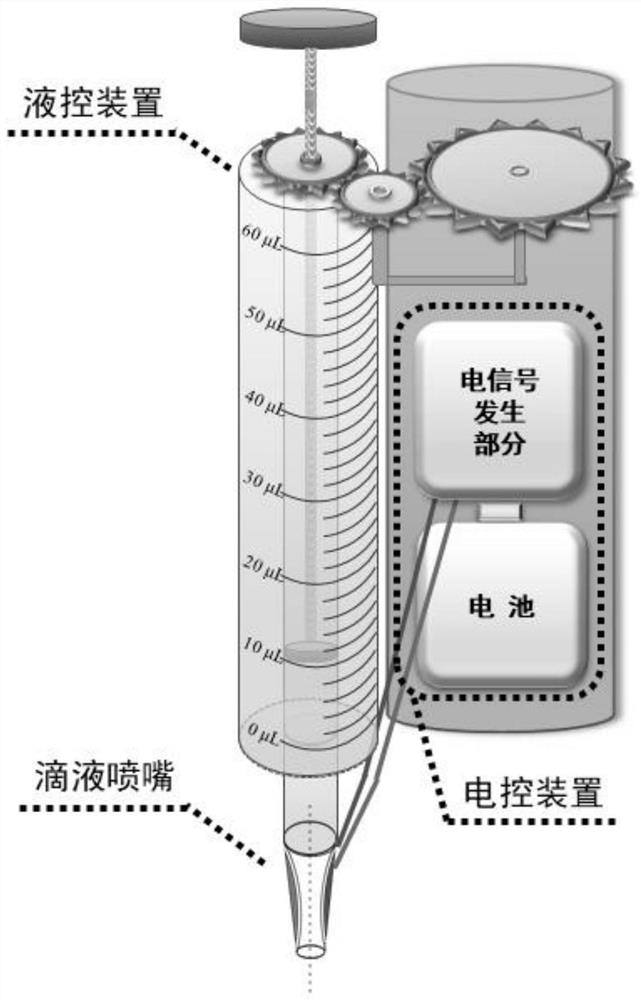

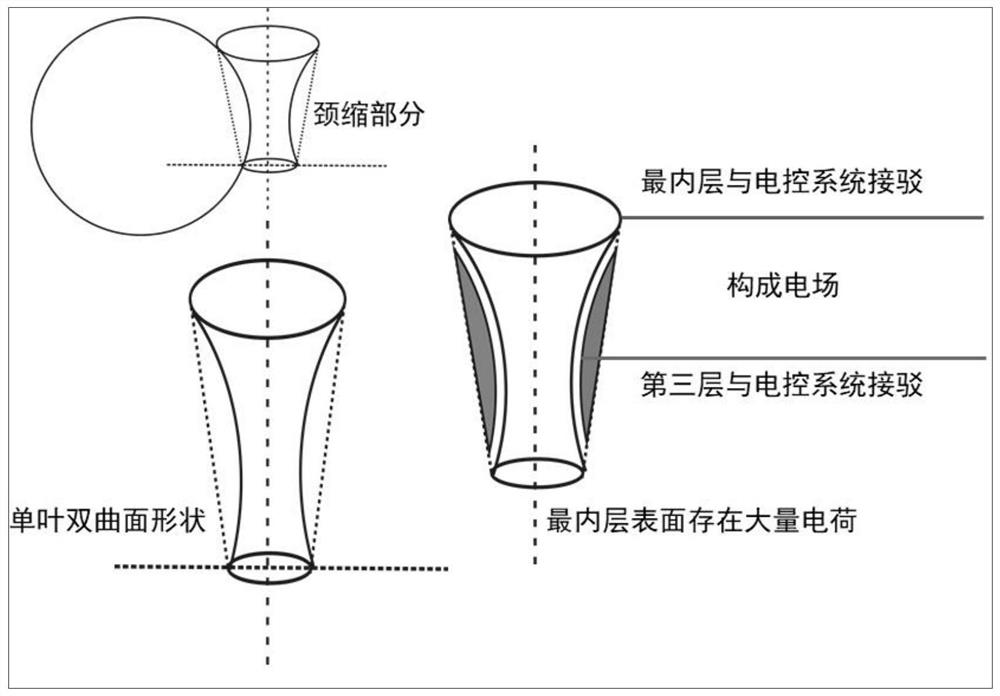

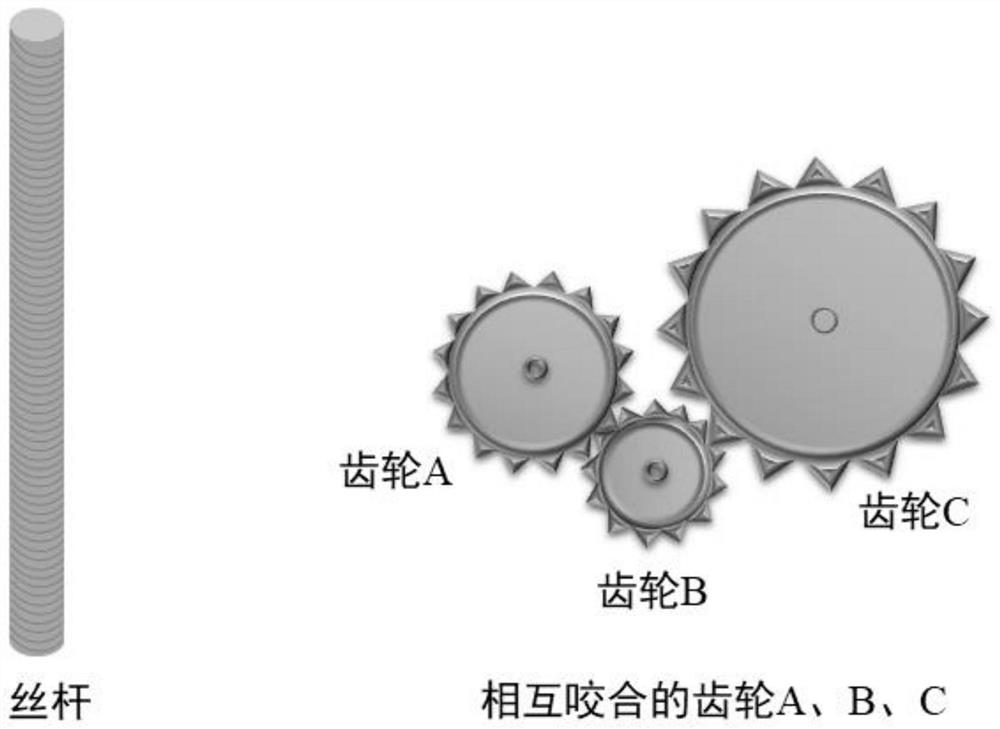

[0045] according to figure 2 A dripping nozzle was produced, wherein the dripping nozzle was a four-layer composite structure in the shape of a single leaf hyperboloid, the diameter of the upper end was 2.6 mm, and the diameter of the lower end was 0.5 mm. The innermost layer is made of stainless steel, the second layer is made of polytetrafluoroethylene, the third layer is made of stainless steel, and the fourth layer is made of polytetrafluoroethylene.

[0046] The electric control device is powered by a storage battery and includes an electrical signal generator based on the NE555 circuit. It can output electrical pulse signals or DC signals with a frequency of 0-10MHz and a magnitude of -30-60V. The output end of the pulse signal is connected to the innermost layer (first conductive layer) of the droplet nozzle, and the zero line end is connected to the third layer (second conductive layer) of the droplet nozzle, so as to build a pulse electric field in the droplet nozzl...

Embodiment 2

[0050] according to figure 2 A dripping nozzle was produced, wherein the dripping nozzle was a four-layer composite structure with a single-leaf hyperboloid, the diameter of the upper end was 3.5 mm, and the diameter of the lower end was 0.6 mm. The innermost layer is made of magnesium-aluminum alloy, the second layer is made of polyimide, the third layer is made of magnesium-aluminum alloy, and the fourth layer is made of polyimide.

[0051] The electronic control device is powered by a rechargeable battery and includes a pulse signal generator made of two TTL integrated circuits (74LS00 and 74LS221). The electric control module can output electric pulse signals with a frequency of 10-20MHz and a magnitude of -10-100V. The output end of the pulse signal is connected to the innermost layer (first conductive layer) of the droplet nozzle, and the zero line end is connected to the third layer (second conductive layer) of the droplet nozzle, so as to build a pulse electric field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com