Horizontal air chamber flash evaporation dryer for sludge drying

A flash dryer and sludge drying technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of increasing the unit disposal cost of sludge, the failure of the dryer to operate normally, and the large resistance of the flash dryer, etc. Achieve the effect of eliminating sludge sticking to the wall, reducing power consumption and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

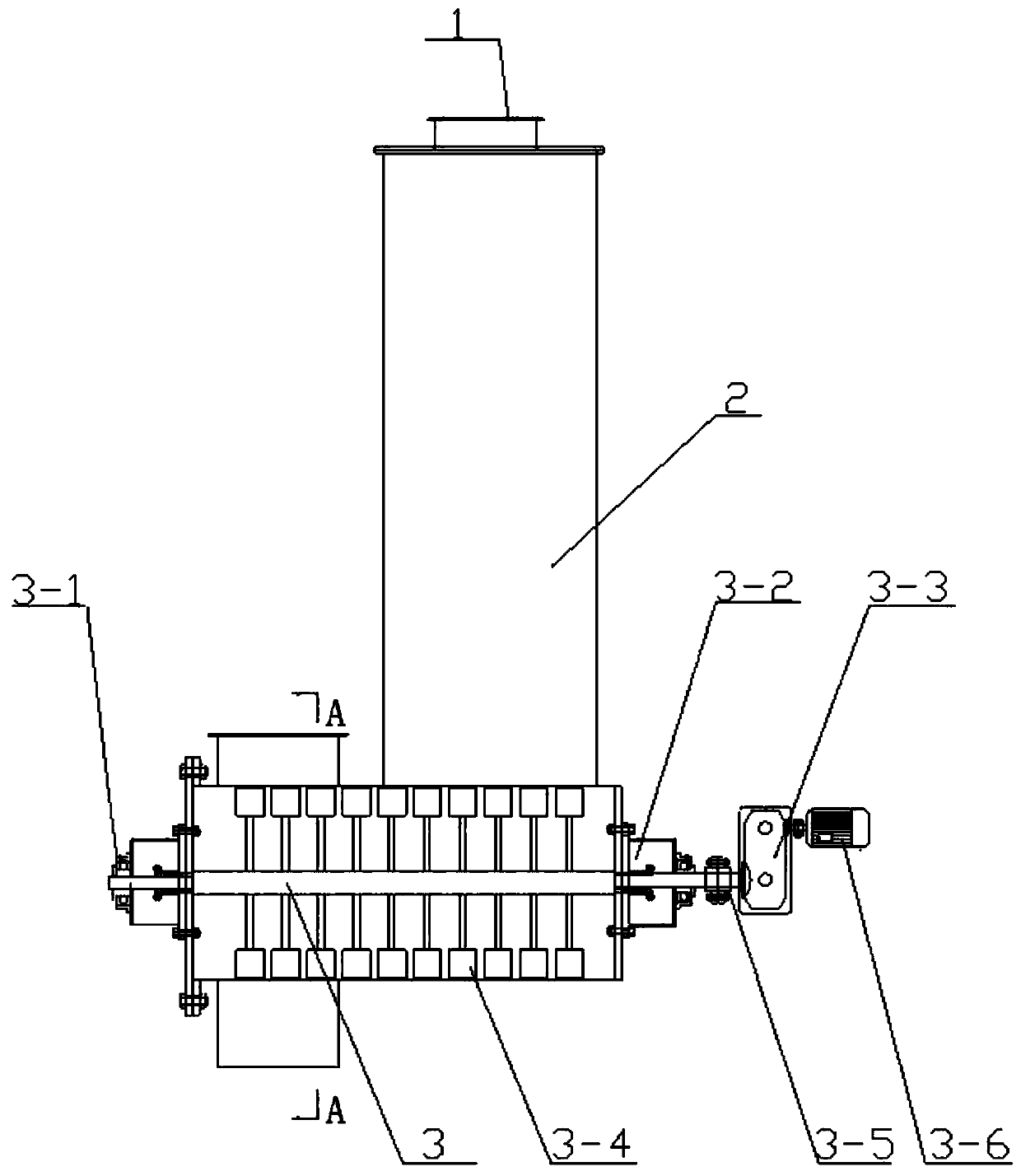

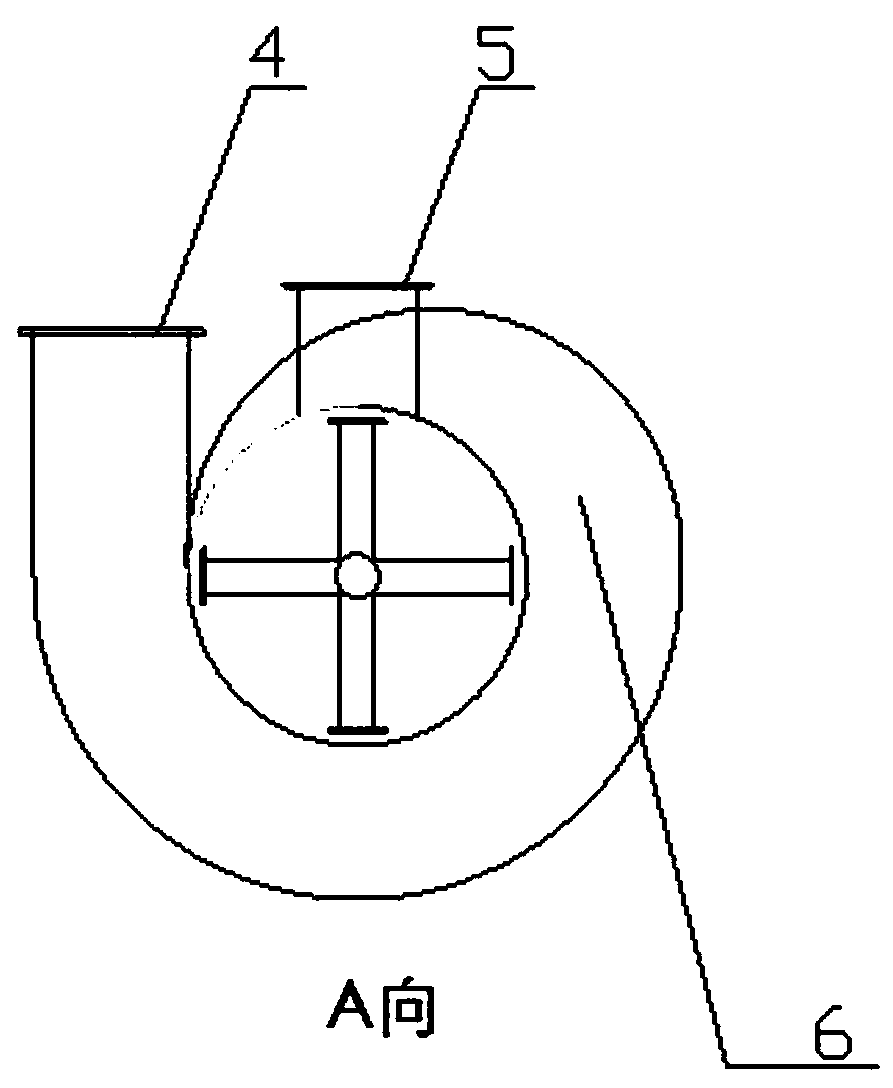

[0020] Such as figure 1 , figure 2 Shown is a horizontal air chamber flash dryer for sludge drying. The dryer includes a drying tower (2), a horizontal stirring device (3), and a horizontal air chamber (6); the horizontal stirring device (3) is connected to the horizontal air chamber (6), and the horizontal stirring device ( 3) Including stirring shaft, left bearing seat (3-1), right bearing seat (3-2), reducer (3-3), lifting plate (3-4), coupling (3-5), motor (3-6); the stirring shaft is provided with a lifting plate, and one end of the stirring shaft is fixedly connected to the housing of the horizontal air chamber (6) through the left bearing seat (3-1); the other end of the stirring shaft One end is connected to the housing of the horizontal air chamber (6) through the right bearing seat (3-2), the stirring shaft is connected to the reducer (3-3) through the coupling (3-5), and the reducer (3 -3) Connect the motor (3-6); the top of the horizontal air chamber (6) is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com