Antibacterial color master batch and preparation method of stock solution colored PET antibacterial functional fiber

A technology of antibacterial color and color masterbatch, which is applied in the preparation of antibacterial color masterbatch and dope-colored PET antibacterial functional fiber, in the field of PET antibacterial functional fiber. Excellent anti-bacterial, good taking performance, reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a kind of antibacterial color masterbatch, by weight percentage, is made up of following raw materials: antibacterial powder is 15%, colorant is 20%, antioxidant is 0.2%, dispersant is 2%, polyester Powder is 62.8%.

[0057] Specifically, the antibacterial powder is composed of the following raw materials in terms of weight percentage: 70% of bisamino-modified silver-loaded lanthanum phosphate antibacterial agent, and 30% of antibacterial metal oxide.

[0058] Specifically, the antibacterial metal oxide is TiO 2 A mixture of nanometer powder and ZnO nanometer powder according to the weight ratio of 1:2.

[0059] Specifically, the polyester powder is composed of the following raw materials in terms of weight percentage: PET powder is 70%, and PBT powder is 30%.

[0060] Specifically, the coloring agent is a red pigment, a bis(p-chlorophenyl)-1,4-diketopyrrolopyrrole red pigment of the diketopyrrolopyrrole type with the brand name Pigment Red 25...

Embodiment 2

[0077] This embodiment provides an antibacterial color masterbatch, the antibacterial color masterbatch is basically the same as Example 1, the only difference is that the antibacterial metal oxide is different. In this embodiment, the antibacterial metal oxide is TiO 2 Nano powder.

[0078] The preparation method of the antibacterial masterbatch of the present embodiment is the same as that of Example 1.

[0079] The preparation method of the dope-colored PET antibacterial functional fiber of this embodiment is the same as that of Embodiment 1.

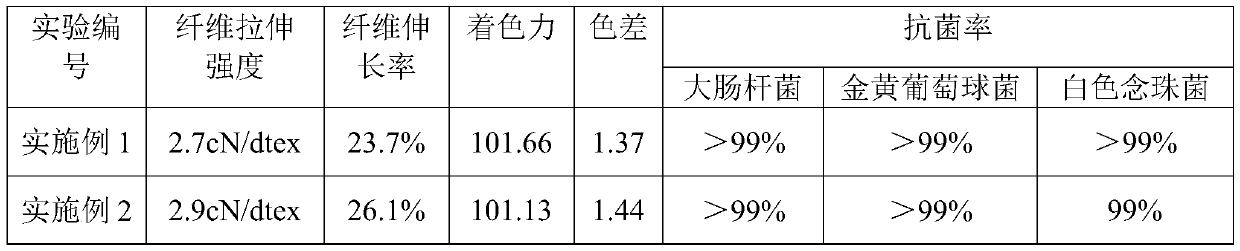

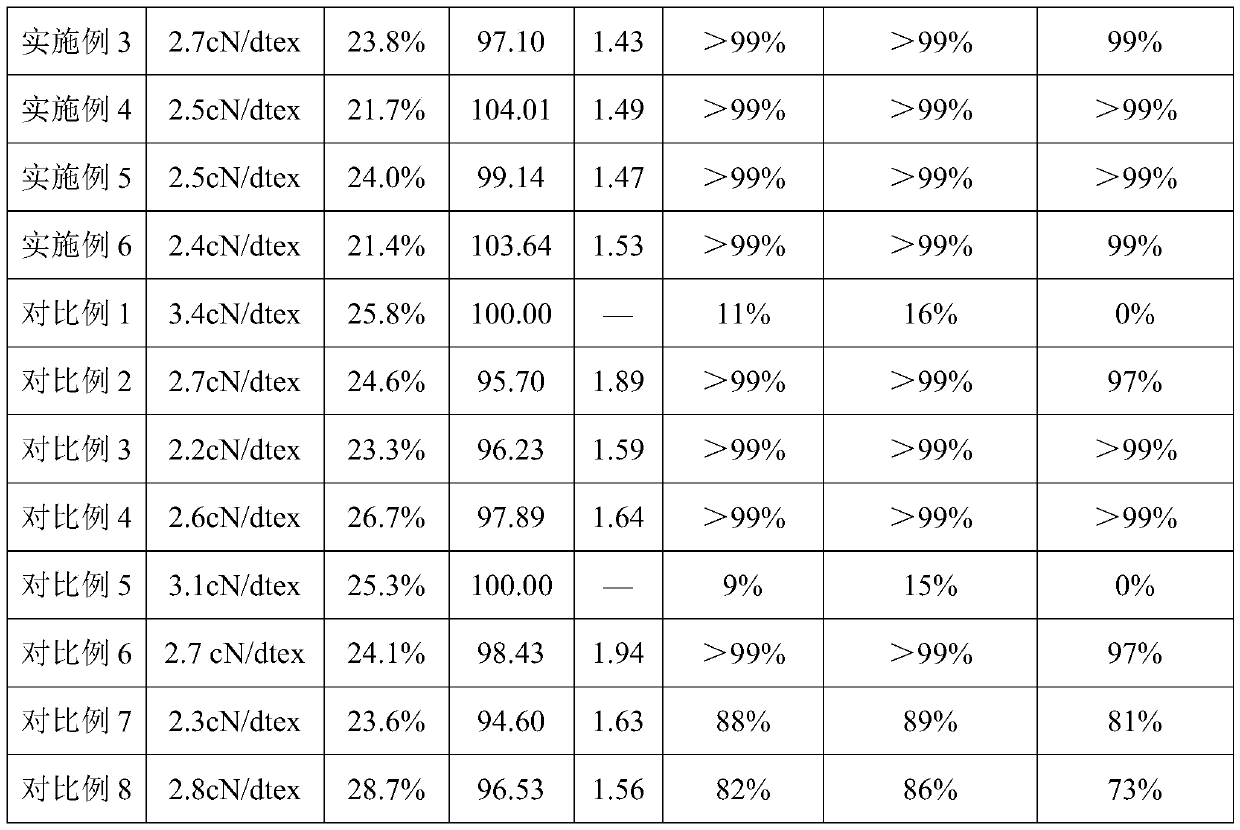

[0080] The antibacterial performance test of the dope-colored PET antibacterial functional fiber prepared in this example was carried out according to the GB / T20944.3-2008 method, and the test results are shown in Table 1.

Embodiment 3

[0082] This embodiment provides an antibacterial color masterbatch, the antibacterial color masterbatch is basically the same as Example 1, the only difference is that the antibacterial metal oxide is different. In this embodiment, the antibacterial metal oxide is ZnO nanopowder.

[0083] The preparation method of the antibacterial masterbatch of the present embodiment is the same as that of Example 1.

[0084] The preparation method of the dope-colored PET antibacterial functional fiber of this embodiment is the same as that of Embodiment 1.

[0085] The antibacterial performance test of the dope-colored PET antibacterial functional fiber prepared in this example was carried out according to the GB / T20944.3-2008 method, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com