Tunnel fabricated prestressed lining design method

A design method and prefabricated technology, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of lining damage and water leakage probability, insufficient consideration of crack resistance, lining quality impact, etc., to ensure quality, reduce water seepage, eliminate effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

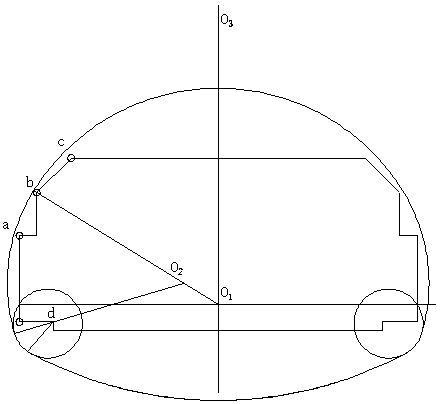

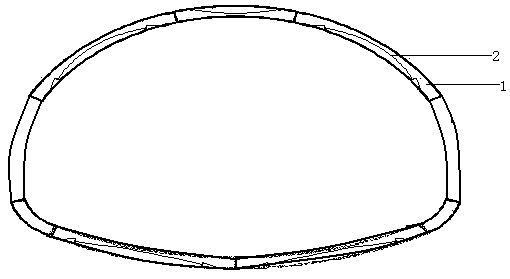

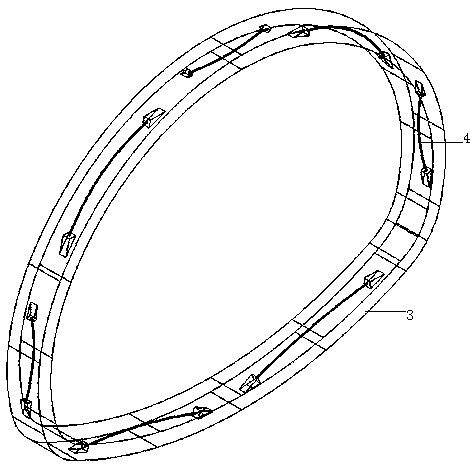

[0021] figure 1 As shown, a method for designing prestressed tunnel prestressed lining, including three processes of structural design and preparation and installation of segmented lining segments; the structural design steps are as follows: Step A: Determine the inner limit of the tunnel and the inner contour of the lining The specific process is as follows, first determine the tunnel boundary according to the vehicle design speed and the actual requirements of the tunnel (travelway width, building boundary height, etc.), and then use polycentric circles to determine the inner contour of the tunnel lining to determine the inner contour (that is, the entire outline of the tunnel), it is divided into 5 small steps, and the results obtained make the subsequent segmented lining segments more in line with the mechanical properties, and to a certain extent prevent the occurrence of lining cracks. When determining the inner contour, the 5 small steps are as follows: (1) Make a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com