High-performance composite positive electrode material as well as preparation method and application thereof

A composite positive electrode material and carbon nanotube technology, which is applied in the direction of nanotechnology, positive electrode, active material electrode, etc. for materials and surface science, can solve the problem of limited cycle life of positive electrode materials, unsatisfactory conductivity of zinc ion positive electrode materials, etc. problem, to achieve the effect of enhanced binding force, excellent specific capacity, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

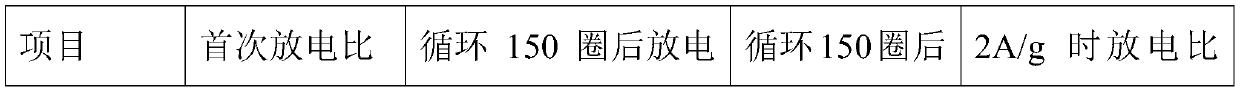

Examples

Embodiment 1

[0086] This embodiment provides a composite positive electrode material, the composite positive electrode material includes: at least the outer surface has MnO 2 Carbon nanotubes with a coating layer (thickness of the coating layer is 3nm), pyrolytic carbon, and dispersed in MnO 2 MnO between coated carbon nanotubes and pyrolytic carbon 2 Nanoparticles;

[0087] Taking the mass of the composite positive electrode material as 100%, the mass percentage of carbon nanotubes is 4%, MnO 2 cladding layer and MnO 2 The mass percentage of the total amount of nanoparticles is 95%, and the mass percentage of pyrolytic carbon is 1%.

[0088] The preparation method of described composite cathode material comprises the following steps:

[0089] (1) Preparation of outer surface coated with MnO 2 ordered carbon nanotubes

[0090] Immerse the anodized aluminum template (AAO template) with openings at both ends in a polypyrrole solution (0.01 mg / L mass concentration), the mass ratio of th...

Embodiment 2

[0098] This embodiment provides a composite positive electrode material, the composite positive electrode material includes: at least the outer surface has MnO 2 Carbon nanotubes, pyrolytic carbon, and carbon nanotubes with a coating layer (thickness of coating layer 5nm), and dispersed 2 MnO between coated carbon nanotubes and pyrolytic carbon 2 Nanoparticles;

[0099] Taking the mass of the composite cathode material as 100%, the mass percentage of carbon nanotubes is 2%, MnO 2 cladding layer and MnO 2 The mass percentage of the total amount of nanoparticles is 96%, and the mass percentage of pyrolytic carbon is 2%.

[0100] The preparation method of described composite cathode material comprises the following steps:

[0101] (1) Preparation of outer surface coated with MnO 2 ordered carbon nanotubes

[0102] The anodized aluminum template (AAO template) with openings at both ends was immersed in a polypyrrole solution (mass concentration of 0.5 mg / L), the mass ratio o...

Embodiment 3

[0110] This embodiment provides a composite positive electrode material, the composite positive electrode material includes: at least the outer surface has MnO 2 Carbon nanotubes, pyrolytic carbon, and carbon nanotubes with a coating layer (thickness of the coating layer 10nm), and dispersed in MnO 2 MnO between coated carbon nanotubes and pyrolytic carbon 2 Nanoparticles;

[0111] Taking the mass of the composite positive electrode material as 100%, the mass percentage of carbon nanotubes is 3%, MnO 2 cladding layer and MnO 2 The mass percentage of the total amount of nanoparticles is 90%, and the mass percentage of pyrolytic carbon is 7%.

[0112] The preparation method of described composite cathode material comprises the following steps:

[0113] (1) Preparation of ordered carbon nanotubes

[0114] The anodized aluminum template (AAO template) with openings at both ends was immersed in a polypyrrole solution (mass concentration of 0.1 mg / L), the mass ratio of AAO temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com