Double-stator motor, motor control system and control method

A technology of motor control and motor controller, applied in control systems, AC motor control, AC motor acceleration/deceleration control, etc., can solve the problem of high loss of flat wire windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] By the above-described drawings, embodiments have been illustrated embodiment of the present invention is clear, it will be hereinafter described in more detail. These figures and written description are not intended to in any way limit the scope of the inventive concept, but by reference to specific embodiments to those skilled in the inventive concept described.

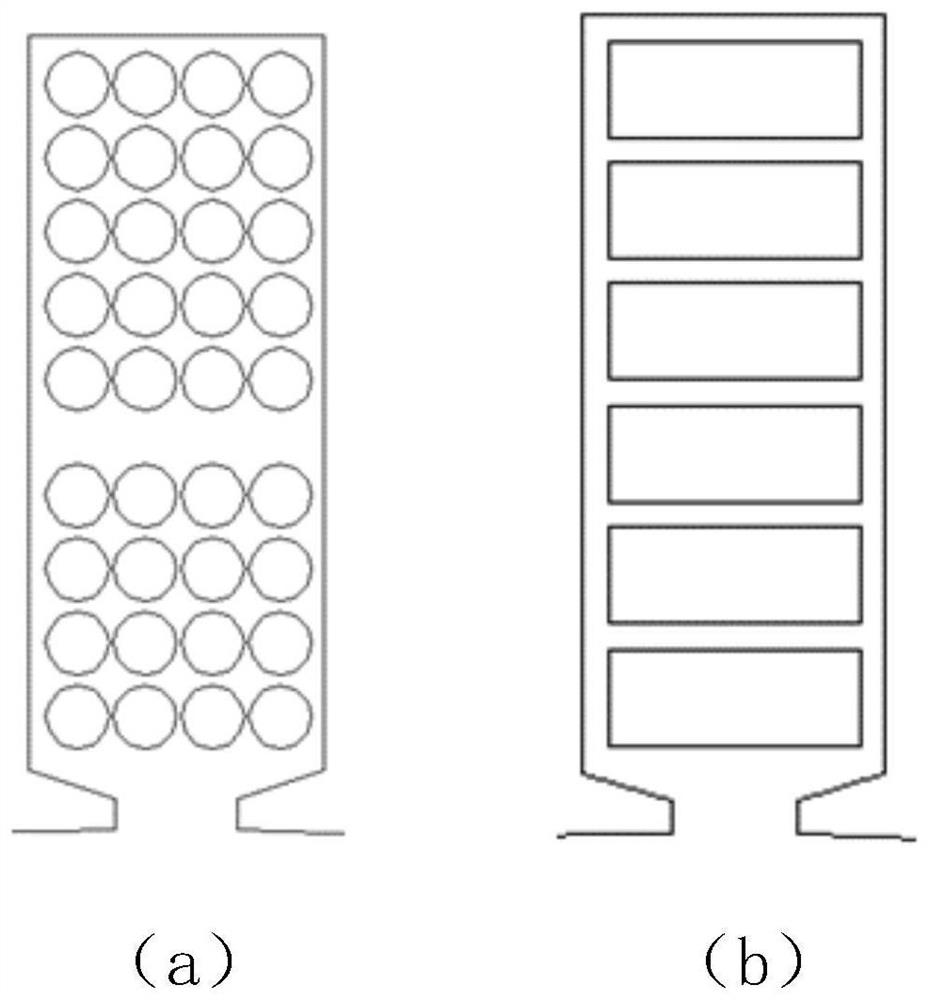

[0052] figure 1 Round flat wire windings and winding a schematic structural diagram of the embodiment of the present invention, wherein figure 1 In (a) is a schematic view of a circular cross section wire windings, figure 1 In (b) is a schematic structural cross-winding flat wire section. Stator winding is generally used round wire windings, the advantage of a simple wound, a good process and high heat dissipation efficiency. But the motor output is closely related to the performance of the motor structure parameters under different operating conditions, while the stator winding motor output is an important fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com