Combined collecting agent for improving molybdenum recovery rate of low-copper high-molybdenum ore and application process thereof

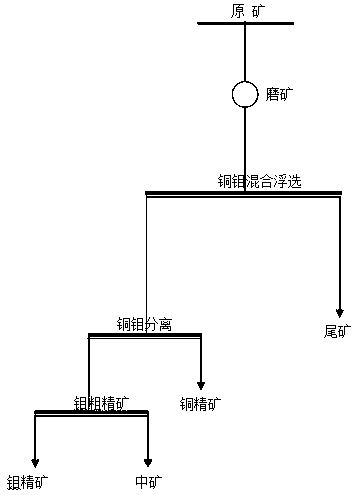

A combination of collector and recovery technology, which is applied to the improvement of process efficiency, solid separation, flotation, etc., can solve the problems of insufficient grinding fineness, high molybdenum content in tailings, and low molybdenum recovery rate. , to achieve the effects of easy industrialization, less selection times, and high molybdenum recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1, a combined collector for improving the molybdenum recovery rate of low-copper and high-molybdenum ores, made of the following raw materials in parts by weight: 2-5 fractionated kerosene higher than 220°C; 1-2 heavy wax; 2 motor oil ~3; tricyclic aromatic hydrocarbons 1~2; emulsifier ⅴ fatty acid polyethanol ester 1~3.

Embodiment 2

[0018] Embodiment 2, in the combined collector for improving the molybdenum recovery rate of low-copper and high-molybdenum ore described in Embodiment 1, it is made of the following raw materials in parts by weight: kerosene 2 of fractionation grade higher than 220 ° C; heavy wax 1; motor Oil 2; Tricyclic aromatic hydrocarbon 1; Emulsifier v Fatty acid polyglycol ester 1.

Embodiment 3

[0019] Embodiment 3, in the combined collector for improving the molybdenum recovery rate of low-copper and high-molybdenum ore described in embodiment 1 or 2, it is made of the following raw materials in parts by weight: fractionated kerosene 5 higher than 220°C; heavy wax 2 ; motor oil 3; tricyclic aromatic hydrocarbon 2; emulsifier ⅴ fatty acid polyglycol ester 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com