Composite cross-linked structure reinforced sludge coagulation modifier and application thereof

A cross-linked structure and composite technology, applied in the direction of fixed/solidified sludge treatment, sludge treatment, sludge detoxification, etc., can solve the problems of waste of resources, increase construction costs, etc., and achieve the effect of ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

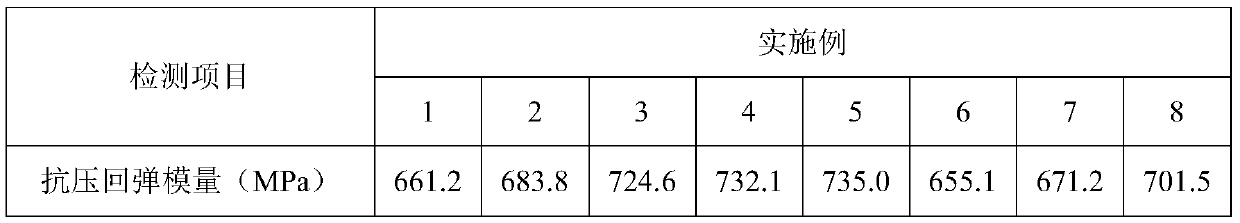

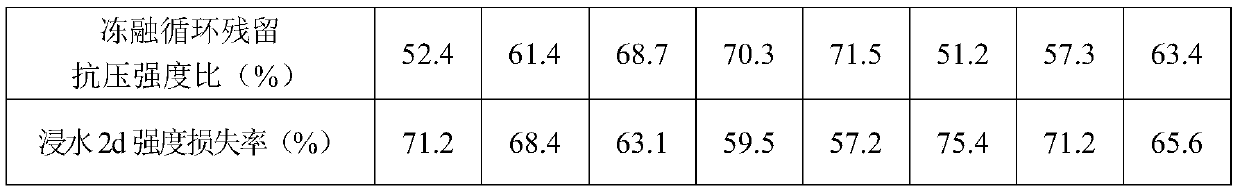

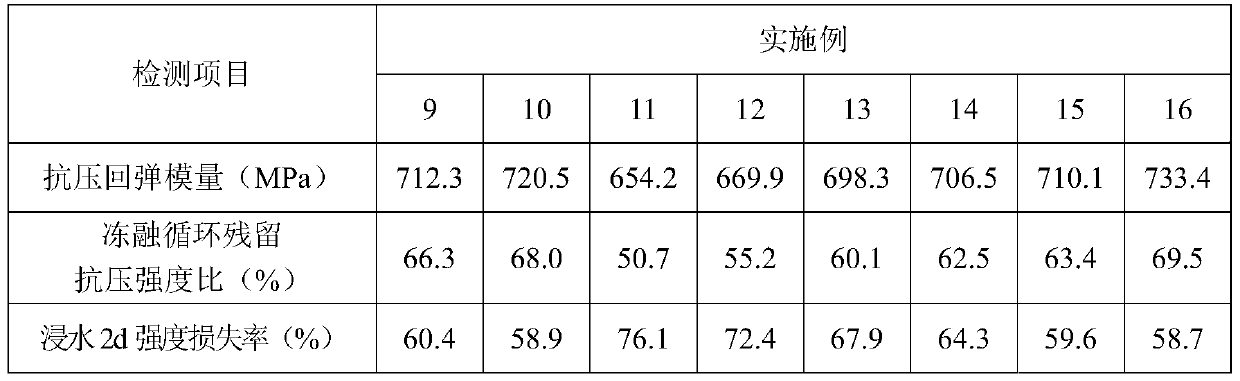

Embodiment 1

[0033] A composite cross-linked structure strengthening sludge coagulation modifier, comprising the following components in parts by mass: 100 parts of sisal fiber, 1 part of guar gum powder, 15 parts of aluminum silicate, cross-linked carboxymethyl fiber 1 part of plain grafted acrylamide, 0.5 part of macromolecular polyurea resin BY-21510, 2 parts of stearamide, 0.5 part of thiophanate-methyl.

Embodiment 2

[0035] A composite cross-linked structure strengthening sludge coagulation modifier, comprising the following components in parts by mass: 100 parts of sisal fiber, 1.6 parts of guar gum powder, 17 parts of aluminum silicate, cross-linked carboxymethyl fiber 1.4 parts of plain grafted acrylamide, 1.5 parts of macromolecular polyurea resin BY-21510, 2.8 parts of stearamide, and 0.7 parts of thiophanate-methyl.

Embodiment 3

[0037] A composite cross-linked structure strengthening sludge coagulation modifier, comprising the following components in parts by mass: 100 parts of sisal fiber, 2 parts of guar gum powder, 18 parts of aluminum silicate, cross-linked carboxymethyl fiber 1.8 parts of plain grafted acrylamide, 1.9 parts of macromolecular polyurea resin BY-21510, 3 parts of stearamide, and 0.8 parts of thiophanate-methyl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com