A direct-throwing high-viscosity toughness high-viscosity modifier and its preparation method

A direct-input, high-viscosity technology, applied in the field of asphalt modifiers, can solve the problems of reduced viscosity and toughness of asphalt mixtures, improve the high-temperature bonding performance of asphalt, use simple methods, and improve road rutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

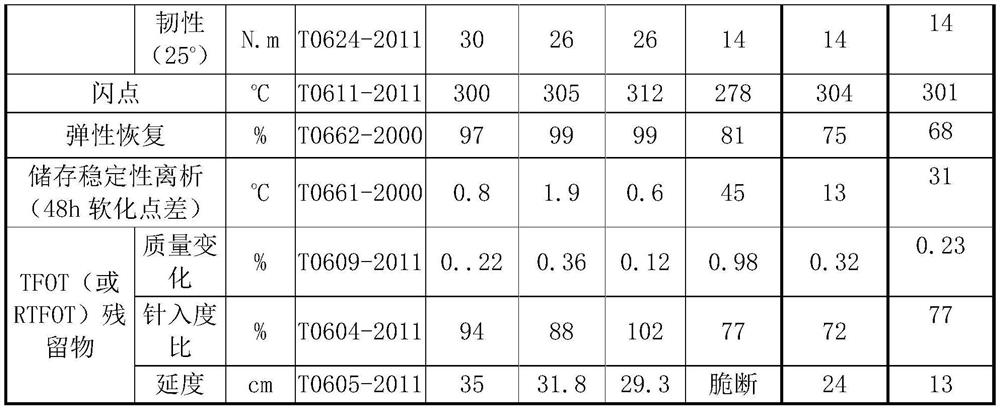

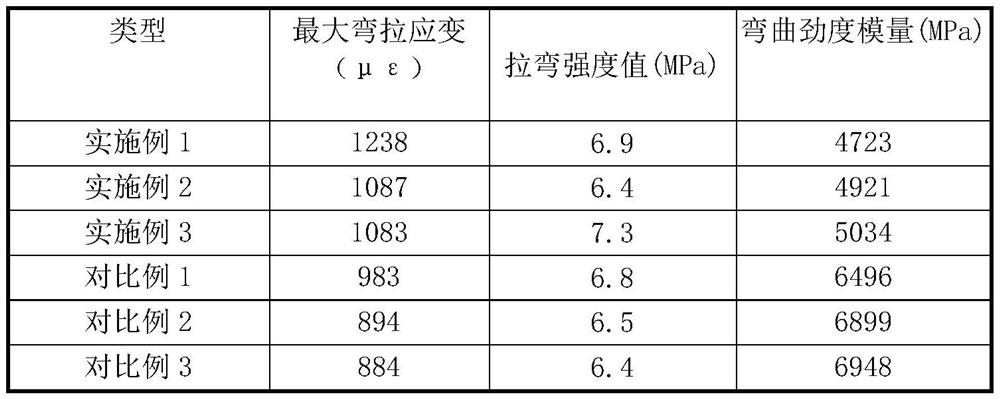

Examples

Embodiment 1

[0025] This embodiment provides a direct-throwing high-viscosity and high-viscosity modifier, which is mainly prepared from the following components in parts by weight: 20 parts of Pebax elastomer, 8.5 parts of polyglycolic acid resin, 70 parts of parts of K resin, 0.5 part of erucamide, 0.5 part of antioxidant 1010, 0.5 part of talc.

[0026] The present embodiment also provides a preparation method of the modifier, which specifically includes the following steps:

[0027] Step 1, the above-mentioned corresponding parts by weight of Pebax elastomer, polyglycolic acid resin, K resin, erucamide, and antioxidant 1010 were mixed in a high-speed mixer for 60min, and the rotating speed was 500rpm. Mixture.

[0028]In step 2, the mixture is melted and kneaded in a twin-screw extruder, the extrusion temperature is 180 ° C, the screw speed is 300 rpm, and then extruded. After cooling and drying, talcum powder is added to obtain a direct-throwing type with high viscosity, toughness an...

Embodiment 2

[0030] This embodiment provides a direct-throwing high-viscosity and high-viscosity modifier, which is mainly prepared from the following components in parts by weight: 35 parts of Pebax elastomer, 13.5 parts of polyglycolic acid resin, 50 parts of parts of K resin, 0.7 parts of erucamide, 0.3 parts of antioxidant 168, 0.5 parts of diatomaceous earth.

[0031] The present embodiment also provides a preparation method of the modifier, which specifically includes the following steps:

[0032] Step 1, the above-mentioned corresponding parts by weight of Pebax elastomer, polyglycolic acid resin, K resin, erucamide, and antioxidant 168 are mixed in a high-speed mixer for 60min, and the rotating speed is 500rpm. Mixture.

[0033] In step 2, the mixture is melted and kneaded in a twin-screw extruder, the extrusion temperature is 180 ° C, the screw speed is 300 rpm, and then extruded, and the anti-adhesive diatomite is added after cooling and drying to obtain a direct injection type....

Embodiment 3

[0035] This embodiment provides a direct-injection high-viscosity and high-viscosity modifier, which is mainly prepared from the following components in parts by weight: 50 parts of Pebax elastomer, 18.2 parts of polyglycolic acid resin, 30 parts of parts K resin, 1 part erucamide, 0.4 part antioxidant 246, 0.4 part talc.

[0036] The present embodiment also provides a preparation method of the modifier, which specifically includes the following steps:

[0037] Step 1, the above-mentioned corresponding parts by weight of Pebax elastomer, polyglycolic acid resin, K resin, erucamide, and antioxidant 246 were mixed in a high-speed mixer for 60 min, and the rotating speed was 500 rpm. Mixture.

[0038] In step 2, the mixture is melted and kneaded in a twin-screw extruder, the extrusion temperature is 180 ° C, the screw speed is 300 rpm, and then extruded. Toughness high viscosity modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com