A production method of high-quality special steel thin steel strip for measuring instruments

A technology for measuring instruments and production methods, which is applied in the field of cold rolling of steel sheets and strips, can solve problems such as inability to meet high-precision requirements, poor flatness of appearance flatness, large fluctuations in thickness tolerances, etc., and achieve good flatness of appearance flatness , product thickness tolerance fluctuation is small, the effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The chemical degreasing liquid used in this embodiment is a commercially available product, the brand DOWELL-P502, and its main components are sodium hydroxide NaOH (≥51%), sodium carbonate NaOH 2 CO 3 , additives; the electrolytic degreasing solution is a commercially available product, the brand name DOWELL-P503, and the main components are sodium hydroxide NaOH (≥54%), sodium carbonate NaOH 2 CO 3 ,additive.

[0051] (1) In this embodiment, the key element content range of the raw material 65Mn is optimally controlled: the C content is 0.65-0.68%, the Si content is 0.2-0.3%, the Mn content is 1.0-1.2%, and the P content is ≤0.03%. The S content is ≤0.015%, the Ni content is ≤0.25%, the Cr content is ≤0.25%, and the Cu content is ≤0.25%.

[0052] (2) Annealing process: In this embodiment, the heating rate is reduced, the temperature of primary annealing and secondary annealing is appropriately increased, and the holding time is prolonged.

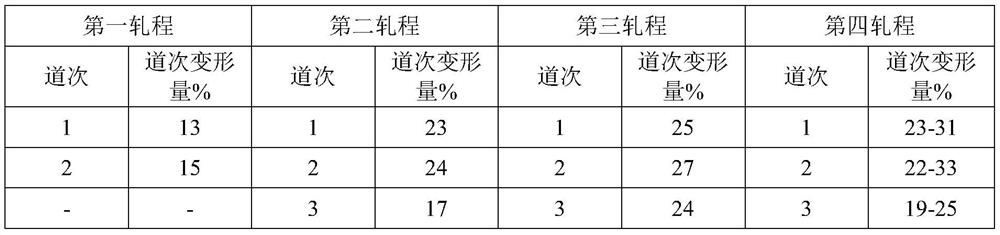

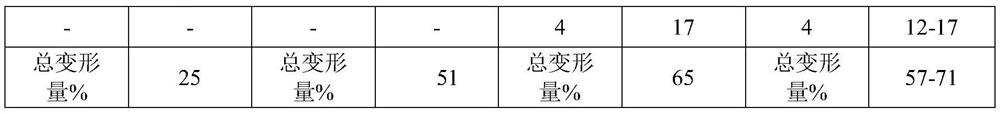

[0053] table 3

[0054] ...

Embodiment 2

[0093] The chemical degreasing solution and the electrolytic degreasing solution used in this embodiment are the same as those in Example 1.

[0094] The product prepared in this embodiment is a high-end measuring instrument with a thickness of 0.12mm and a width of 154mm, which is an excellent special steel strip.

[0095] The present embodiment adopts the following steps to prepare:

[0096] (1) Selection of raw materials: The thickness is 2.75mm, the width is 1250mm, the grade is 65Mn hot-rolled pickling coil steel strip, and its chemical composition: C content 0.67%, Si content 0.23%, Mn content 1.1%, P content 0.025 %, S content 0.012%, Ni content 0.20%, Cr content 0.21%, Cu content 0.19%.

[0097] (2) Slitting the raw material of hot-rolled pickled coils with a raw material slitting unit at a speed of 100m / min.

[0098] (3) The raw material of the hot-rolled pickled coil after slitting is cold-rolled for the first time with an 850 six-high reversing rolling mill, with ...

Embodiment 3

[0118] The chemical degreasing solution and the electrolytic degreasing solution used in this embodiment are the same as those in Example 1.

[0119] The product prepared in this embodiment is a high-end measuring instrument with a thickness of 0.10mm and a width of 154mm, which is an excellent special steel strip.

[0120] The present embodiment adopts the following steps to prepare:

[0121] (1) Selection of raw materials: The thickness is 2.75mm, the width is 1250mm, the grade is 65Mn hot-rolled pickling coil steel strip, and its chemical composition: C content 0.65%, Si content 0.2%, Mn content 1.0%, P content 0.021 %, S content 0.010%, Ni content 0.17%, Cr content 0.20%, Cu content 0.22%.

[0122] (2) Slitting the raw material of hot-rolled pickled coils with a raw material slitting unit at a speed of 120m / min.

[0123] (3) The raw material of the hot-rolled pickled coil after slitting is cold-rolled for the first time with an 850 six-high reversing rolling mill, with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com