Novel nano stainless steel

A stainless steel and nano technology, applied in the field of new bulk nano alloy stainless steel, can solve the problems of unsatisfactory mechanical properties of 304 stainless steel, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An embodiment of the novel nano-stainless steel of the present invention, the chemical composition and weight percentage contained in the nano-stainless steel described in this embodiment are: aluminum 1.8%, carbon 0.07%, manganese 2.0%, silicon 1.0%, chromium 18.0%, 10.0% nickel, 0.03% sulfur, 0.035% phosphorus and the balance iron.

[0019] In this embodiment, the sources of each raw material are as follows: the aluminum source is alumina powder with a particle size of 10-50 nm, and other component raw materials are common material sources available on the market.

[0020] In this embodiment, the preparation method of the novel nano-stainless steel is as follows: mixing various raw materials and heating to above 1600° C. for smelting to obtain the novel nano-stainless steel.

Embodiment 2~6 and comparative example 1~2

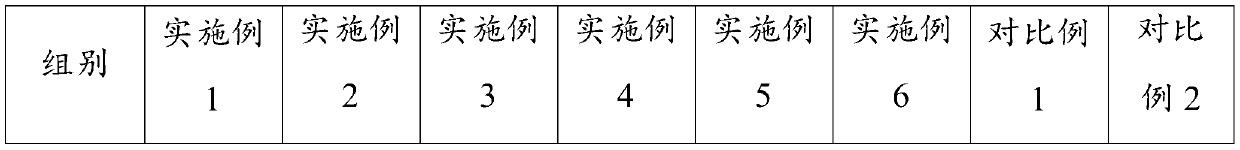

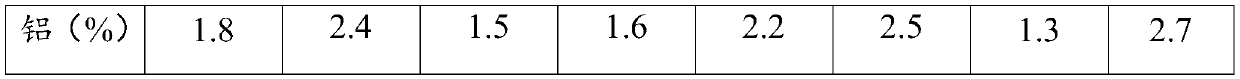

[0022] Embodiments 2~6 and comparative examples 1~2 and the difference of the chemical composition of novel nano-stainless steel described in embodiment 1 are only the difference of aluminum content, and the novel nano-stainless steel described in embodiment 2~6 and comparative examples 1~2 The aluminum content is shown in Table 1.

[0023] The raw material sources and preparation methods of the novel nano-stainless steel described in Examples 2-6 and Comparative Examples 1-2 are the same as those in Example 1.

[0024] Table 1

[0025]

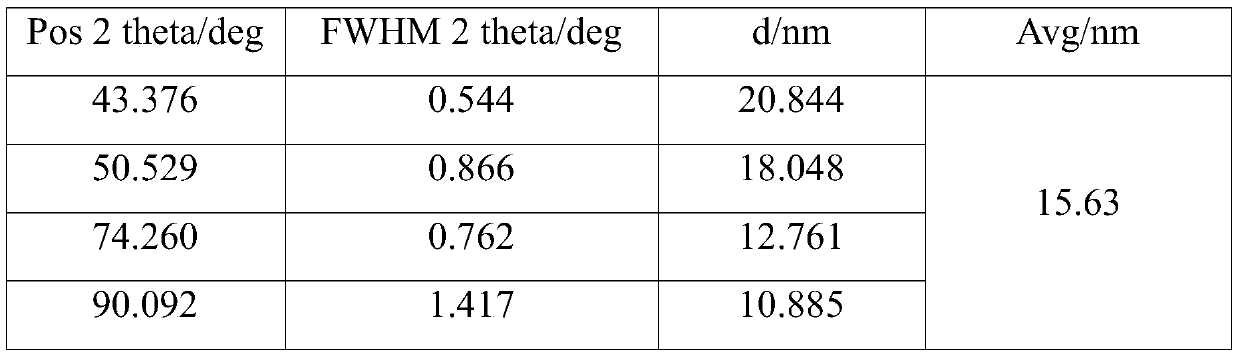

[0026]

Embodiment 7

[0028] An embodiment of the novel nano-stainless steel of the present invention, the chemical composition and weight percentage contained in the nano-stainless steel described in this embodiment are: aluminum 1.6%, carbon 0.07%, manganese 2.0%, silicon 1.0%, chromium 19.0%, 10.0% nickel, 0.03% sulfur, 0.035% phosphorus and the balance iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com