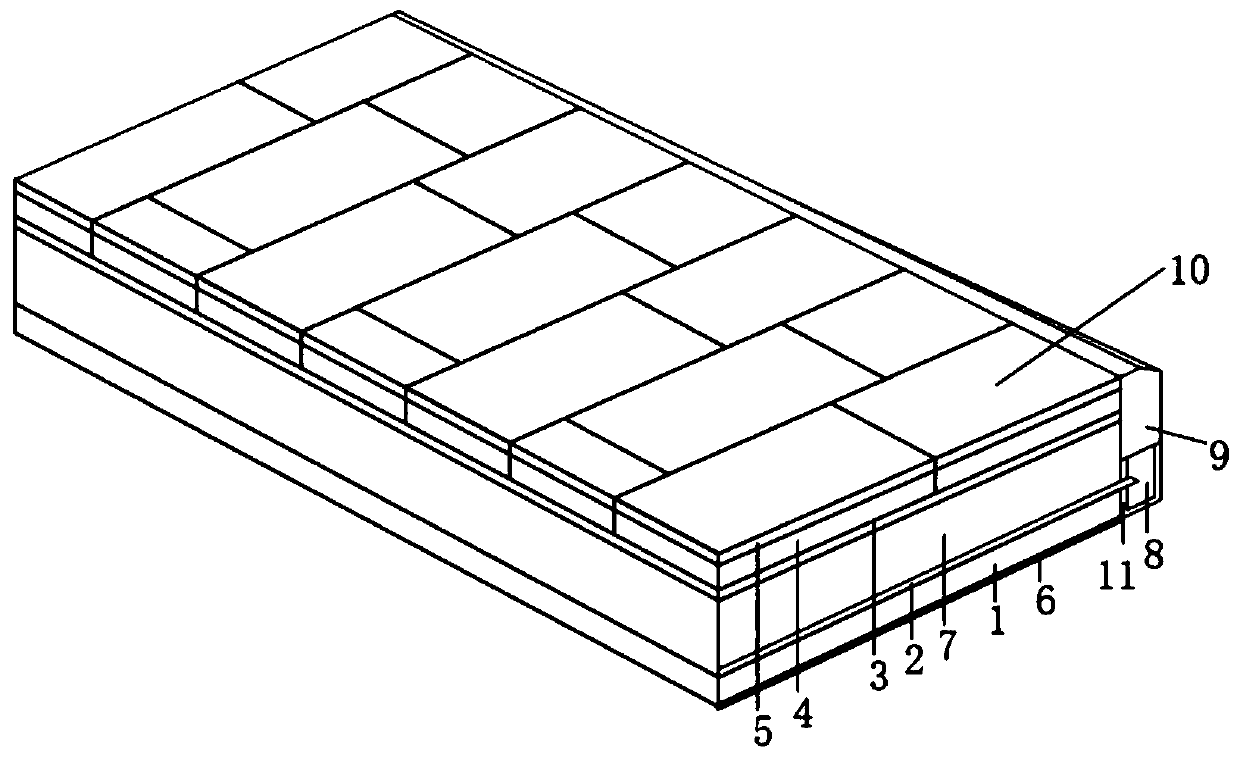

Pervious concrete pavement slab system and pavement slab rainwater collection system

A technology of permeable concrete and road slabs, which is applied in waterway systems, general water supply conservation, roads, etc., and can solve problems that need to be improved, ground water that cannot be discharged in time, urban waterlogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

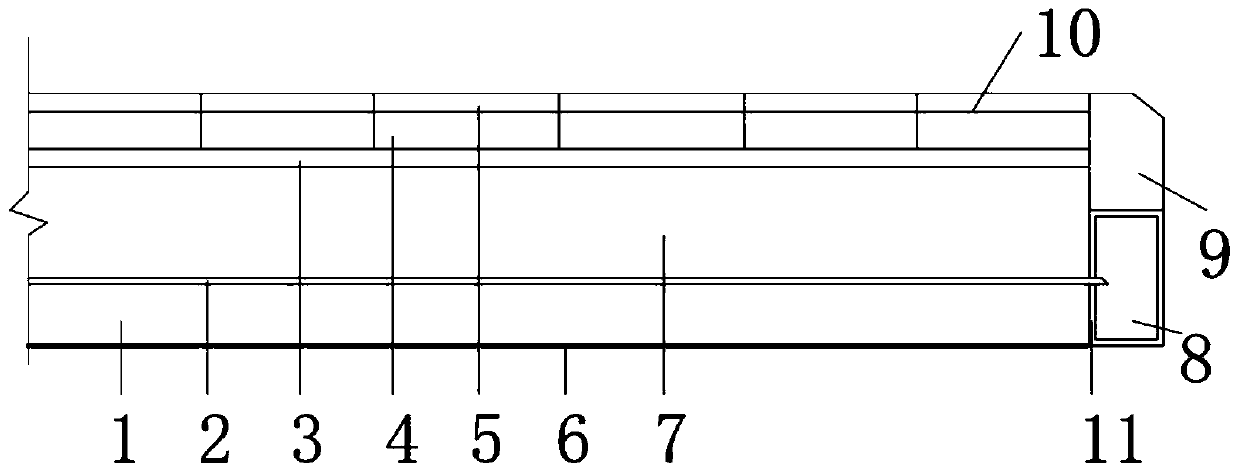

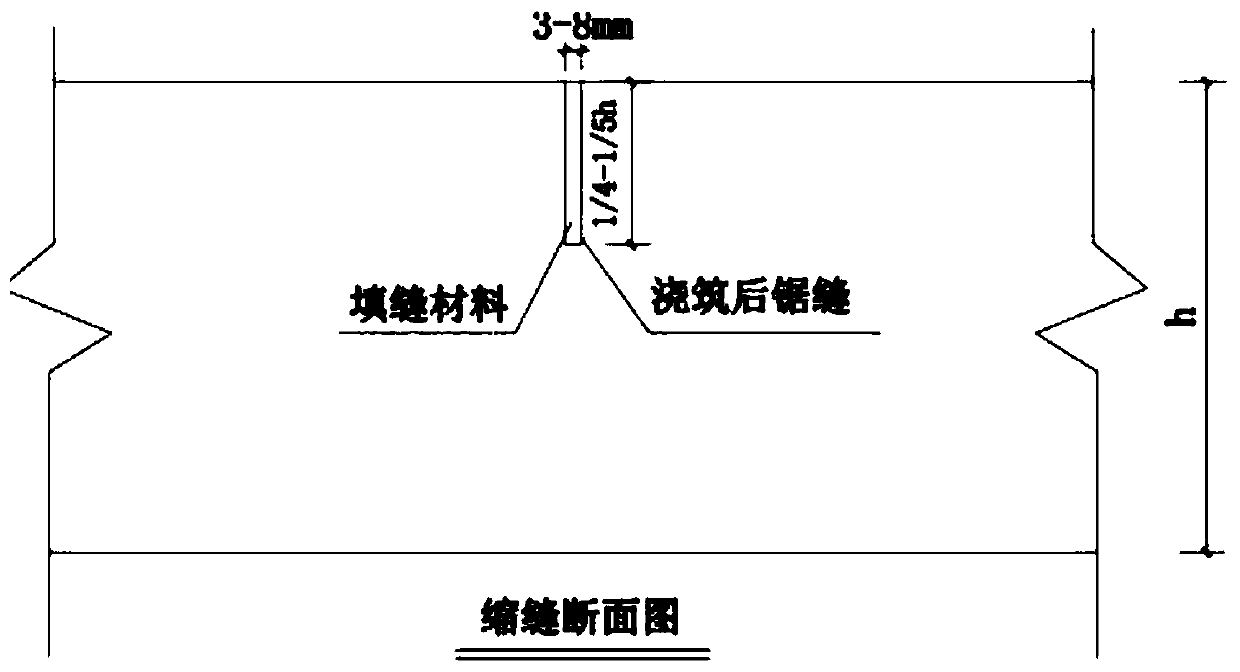

[0055] In the present invention, the preparation method of the base layer preferably includes: mixing water, fly ash, cement, metallurgical slag and a water reducing agent to obtain a slurry; laying the slurry on the surface of the cushion layer, The layer surface forms the base layer. In the present invention, the mixing method is preferably stirring; the paving method is preferably: fixing formwork on both sides of the road according to the actual road width; pouring slurry on site; And control within the required range; after the mixture is completed, it should be maintained in time to maintain a certain humidity, and should not be too dry or too wet; the curing period is preferably not less than 7 days, and it should be covered with geotextiles.

[0056] In the present invention, the thickness of the base layer is preferably 150-180 mm, more preferably 160 nm.

[0057] In the present invention, the bottom of the base layer is provided with a drainage pipe, which can quick...

Embodiment 1~3

[0094] Lay the geotextile on the surface of the foundation first; mix the lime and fly ash to obtain a dry mix, then mix the dry mix with ferrochrome slag (the particle size composition is shown in Table 3) and water, and lay it on the geotextile Cloth surface, forms cushion layer; The consumption of described lime, fly ash, ferrochrome slag and water are shown in Table 5; The thickness of described cushion layer is shown in Table 6;

[0095] Mix water, fly ash, cement and ferrochrome slag (with a particle size of 5 to 20mm), lay it on the surface of the cushion layer, and form a base layer on the surface of the cushion layer; the water, fly ash, cement and ferrochrome slag The dosage is shown in Table 5; the thickness of the base is shown in Table 6;

[0096] At the bottom of the base layer, a perforated high-density polyethylene drainage pipe wrapped with a permeable geotextile is laid horizontally;

[0097] Mix the ferrochrome slag (with a particle size of 0.3-5mm), cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com