Method for improving water flooding effect of water injection well of ultra-low-permeability fractured reservoir

A fracture and oil reservoir technology, applied in the field of improving the water flooding effect of water injection wells in ultra-low permeability fractured oil reservoirs, can solve the problems of poor oil layer physical properties, low matrix seepage capacity, low single well production, etc. The effect of alternate space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (white 404-39 well)

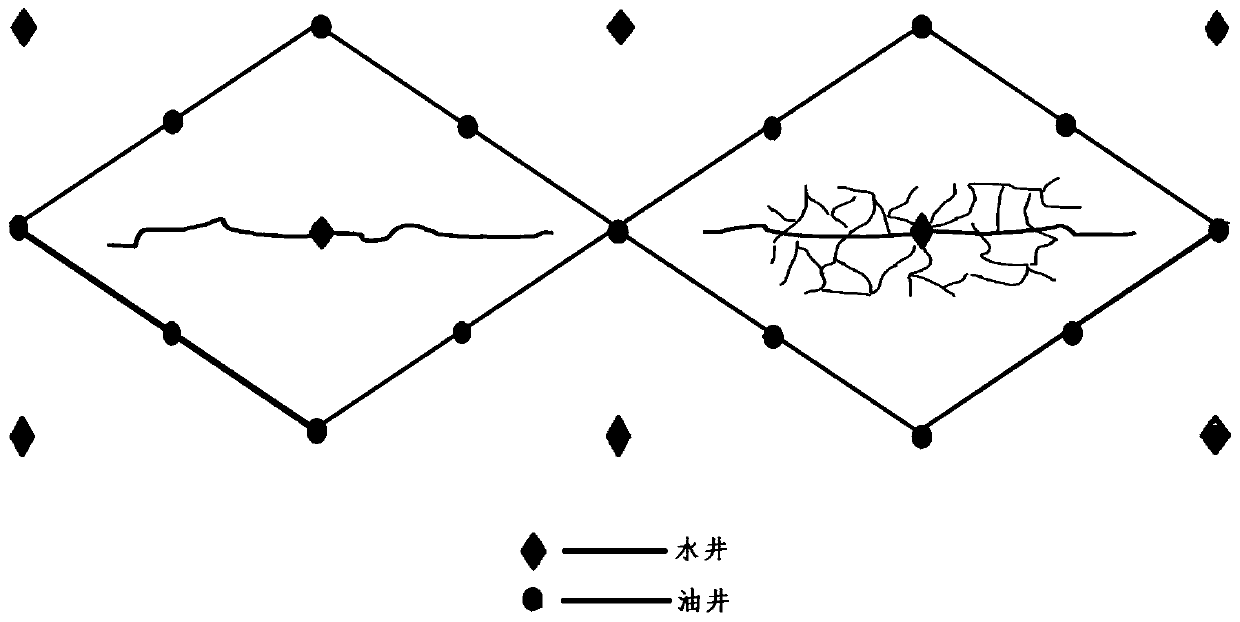

[0028] In order to solve the problem of uneven water flooding caused by the long-term water injection development of ultra-low permeability oilfields, the development of natural micro-fractures, and the formation of dominant water flow channels. This embodiment provides a figure 1 The shown method for improving the water flooding effect of water injection wells in ultra-low permeability fractured reservoirs includes the following steps:

[0029] Step 1: Blocking agent optimization: use CDD-3 blocking agent with a particle size of 3-6mm, and a particle density of 1.06g / cm 3 , the softening point is 40°C, the melting point is 58°C, and 600kg of plugging agent is prepared;

[0030] Step 2: Preparation of proppant: In order to support micro-fractures, proppant only adopts small particle size and reduced dosage to achieve the purpose of lateral water diversion. The proppant particle size is 70-100 mesh, and the dosage is 25m 3 .

[0031...

Embodiment 2

[0035] Step 1: Blocking agent optimization: use CDD-3 blocking agent with a particle size of 3-6mm, and a particle density of 1.06g / cm 3 , the softening point is 40°C, the melting point is 58°C, and 500kg of plugging agent is prepared;

[0036] Step 2: Preparation of proppant: In order to prop up micro-fractures, proppant only adopts small particle size and reduced dosage to achieve the purpose of lateral water diversion. The proppant particle size is 70-100 mesh, and the dosage is 20m 3 .

[0037] Step 3: Plugging agent injection: use guar gum cross-linking fluid to carry the blocking agent, at 3.0m 3 / min displacement, according to the amount of 125 kg for the first stage, 165 kg for the second stage, and 210 kg for the third stage, it is pumped in three stages, and 40m is injected between each stage 3 The base fluid is used as the spacer fluid. After the pumping of the plugging agent is completed, active water is used to clean the plugging agent in the wellbore into the f...

Embodiment 3

[0040] Step 1: Blocking agent optimization: use CDD-3 blocking agent with a particle size of 3-6mm, and a particle density of 1.06g / cm 3 , the softening point is 40°C, the melting point is 58°C, and 570kg of plugging agent is prepared;

[0041] Step 2: Preparation of proppant: In order to support micro-fractures, proppant only adopts small particle size and reduced dosage to achieve the purpose of lateral water diversion. The proppant particle size is 70-100 mesh, and the dosage is 30m 3 .

[0042] Step 3: Plugging agent injection: use guar gum cross-linking fluid to carry the blocking agent, at 3.0m 3 / min displacement, according to the amount of 140 kg for the first stage, 190 kg for the second stage, and 240 kg for the third stage, it is pumped in three stages, and 50m is injected between each stage 3 The base fluid is used as the spacer fluid. After the pumping of the plugging agent is completed, active water is used to clean the plugging agent in the wellbore into the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com