Horizontal oil-free aerodynamic power generation engine

An aerodynamic and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., to achieve the effect of low failure rate, easy maintenance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

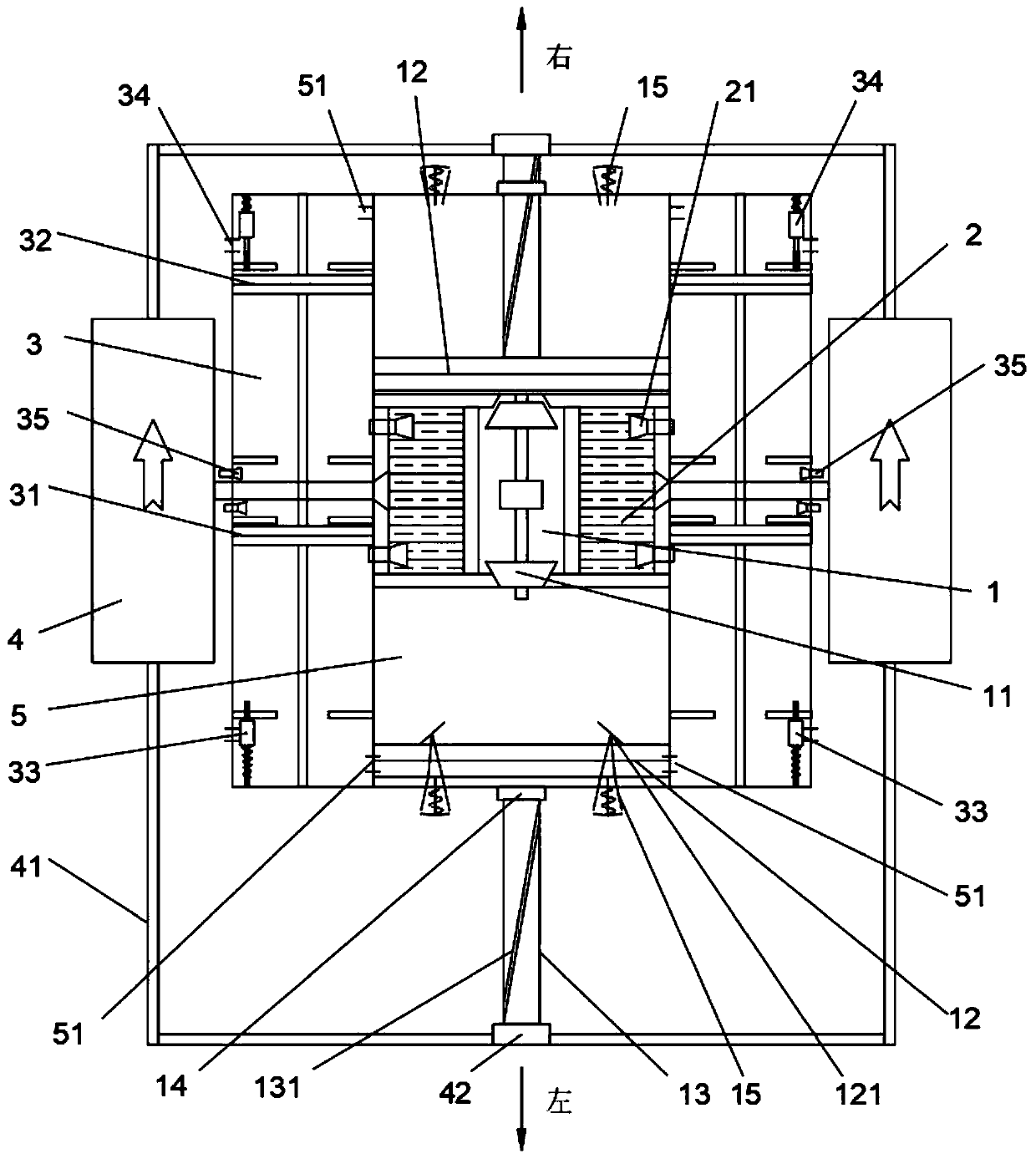

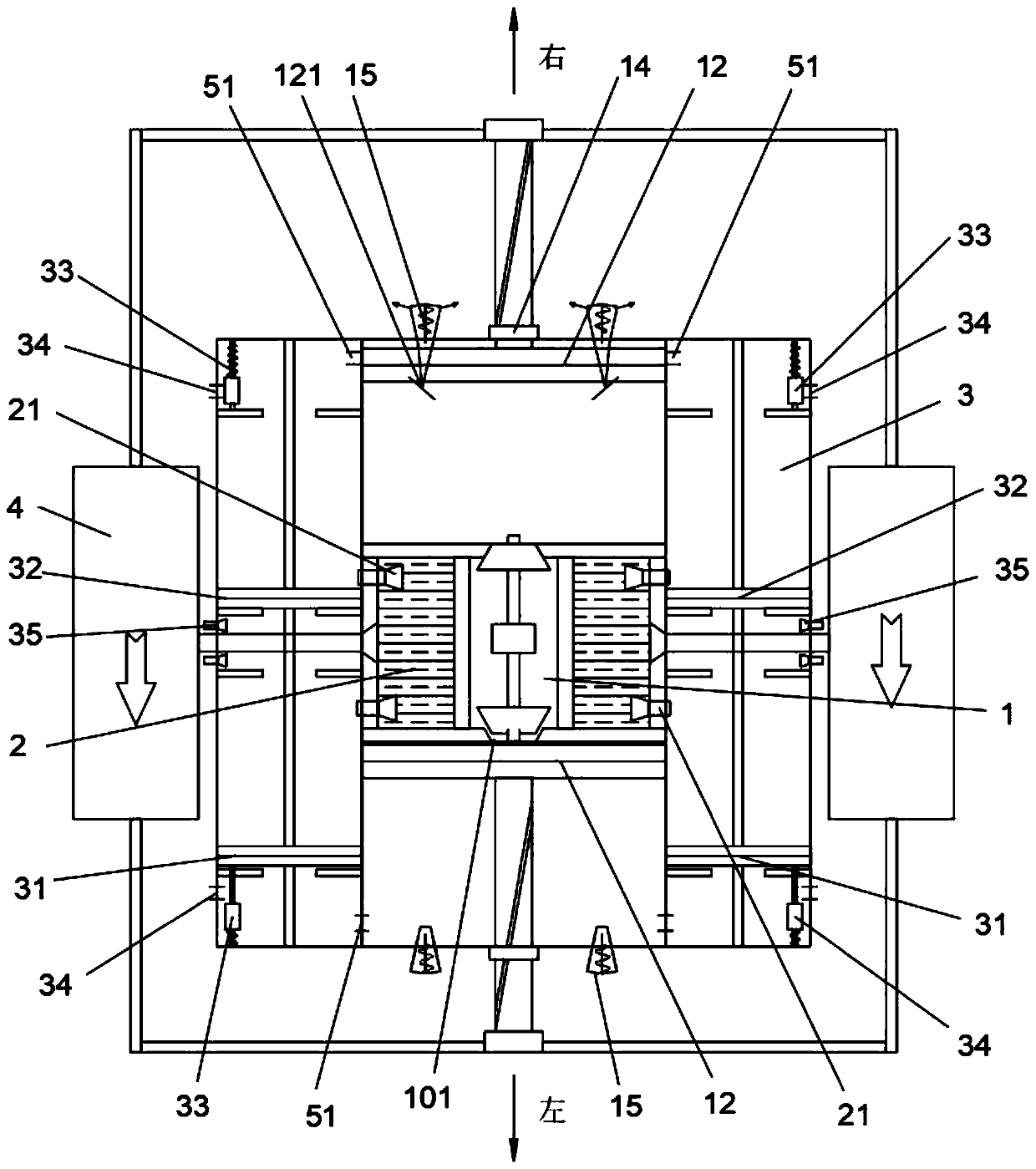

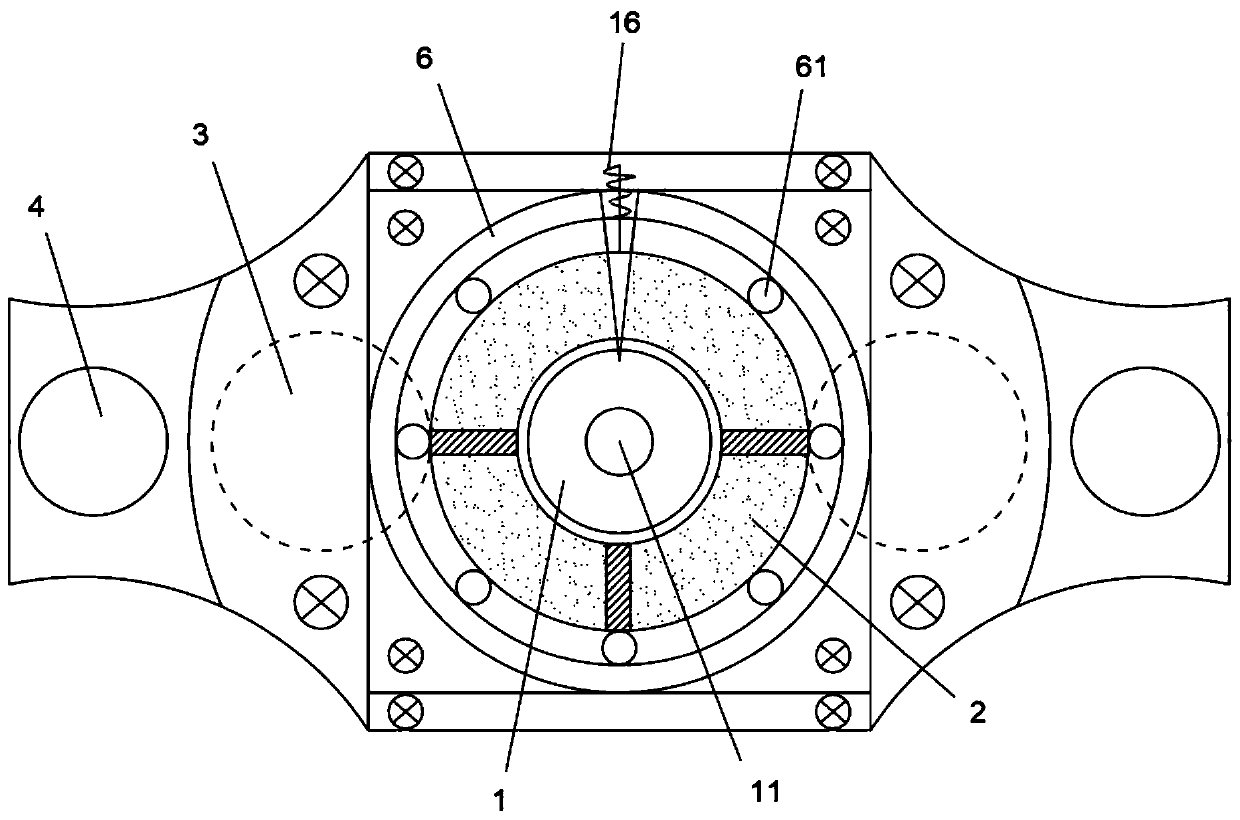

[0034] see Figure 1~3 , in the embodiment of the present invention, the engine of horizontal oil-free air power generation comprises: air pressure transmission cylinder 1, and the inside of air pressure transmission cylinder 1 is provided with two valve plugs 11 connected by fixed brackets, and the two ends of air pressure transmission cylinder 1 are provided with There is an air valve 101; the electric heating room 2, the electric heating room 2 is located on the outer layer of the air pressure transmission cylinder 1, the electric heating element is arranged inside the electric heating room 2, and the vacuum insulation layer 6 is arranged outside the electric heating room 2, and the vacuum insulation Layer 6 is provided with a steel ball fixing layer 61, and the air pressure transmission cylinder 1 is also provided with a control air needle 16 for controlling the air intake between the electric heating chamber 2 and the air pressure transmission cylinder 1; two cylinders 5 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com