Foldable modular packaging, in particular for industrial products

A modular and packaging technology, applied in the directions of packaging, transportation and packaging, rigid containers, etc., can solve the problems of complicated handling and transportation, and achieve the effect of reducing cost and saving volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

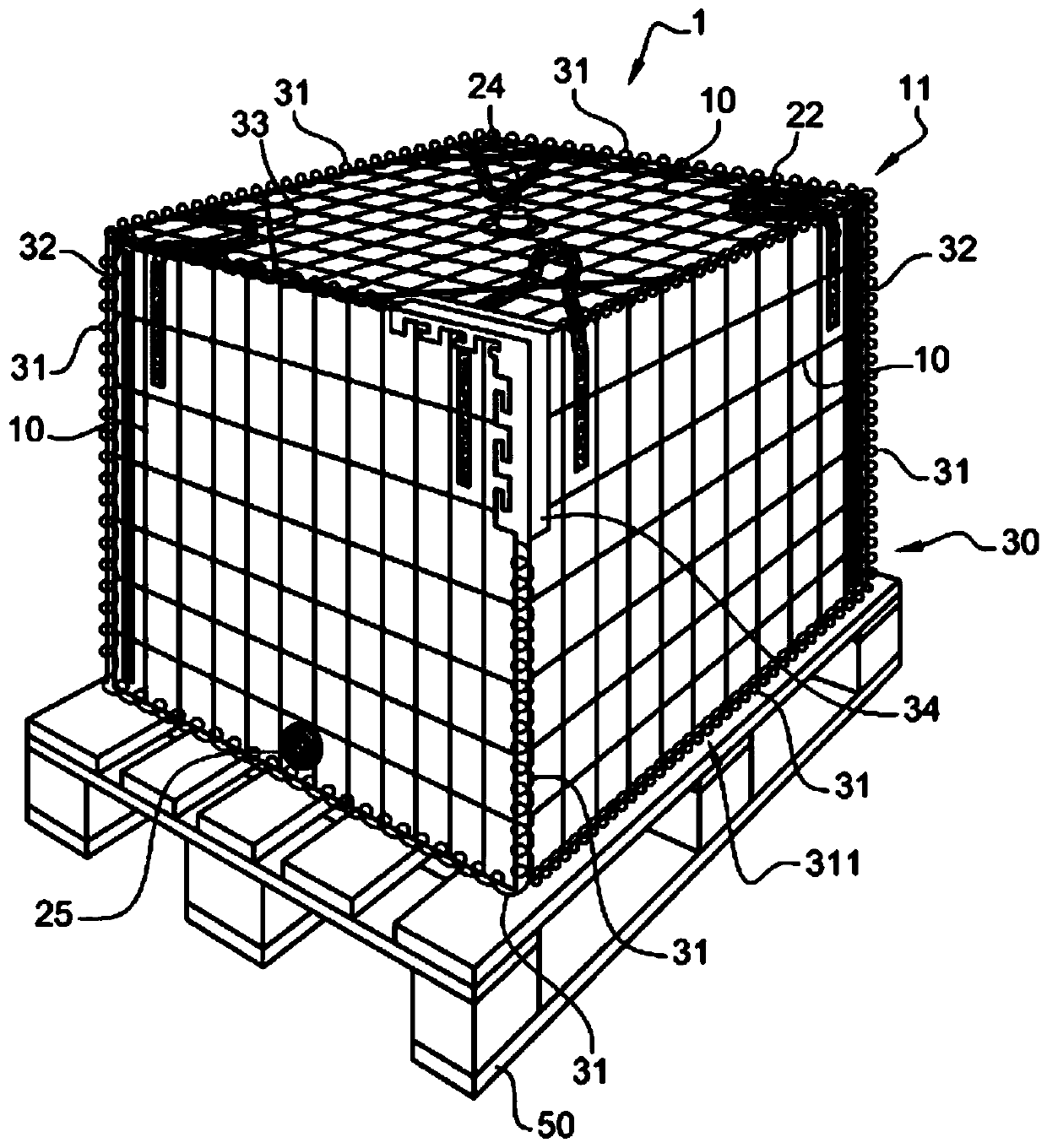

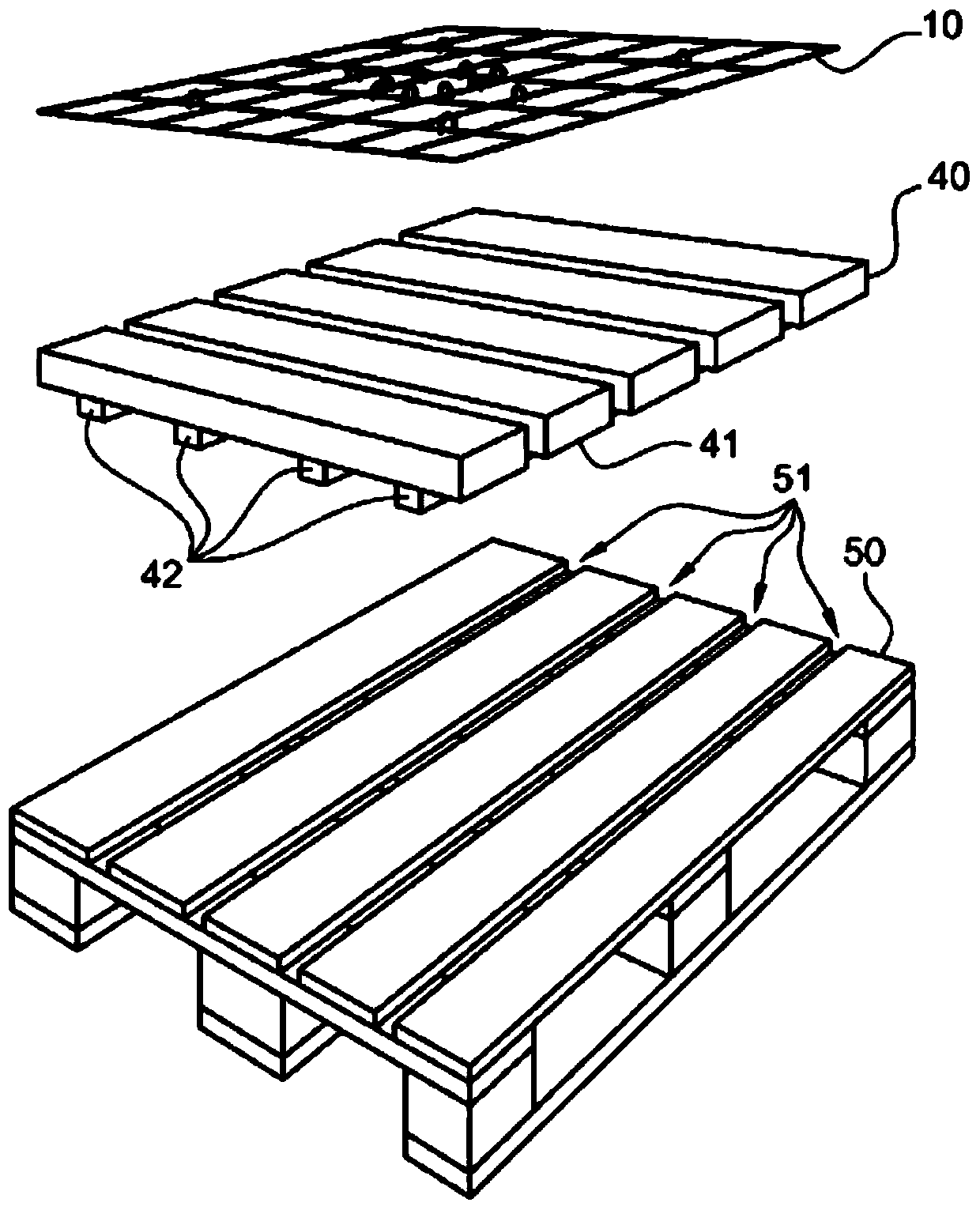

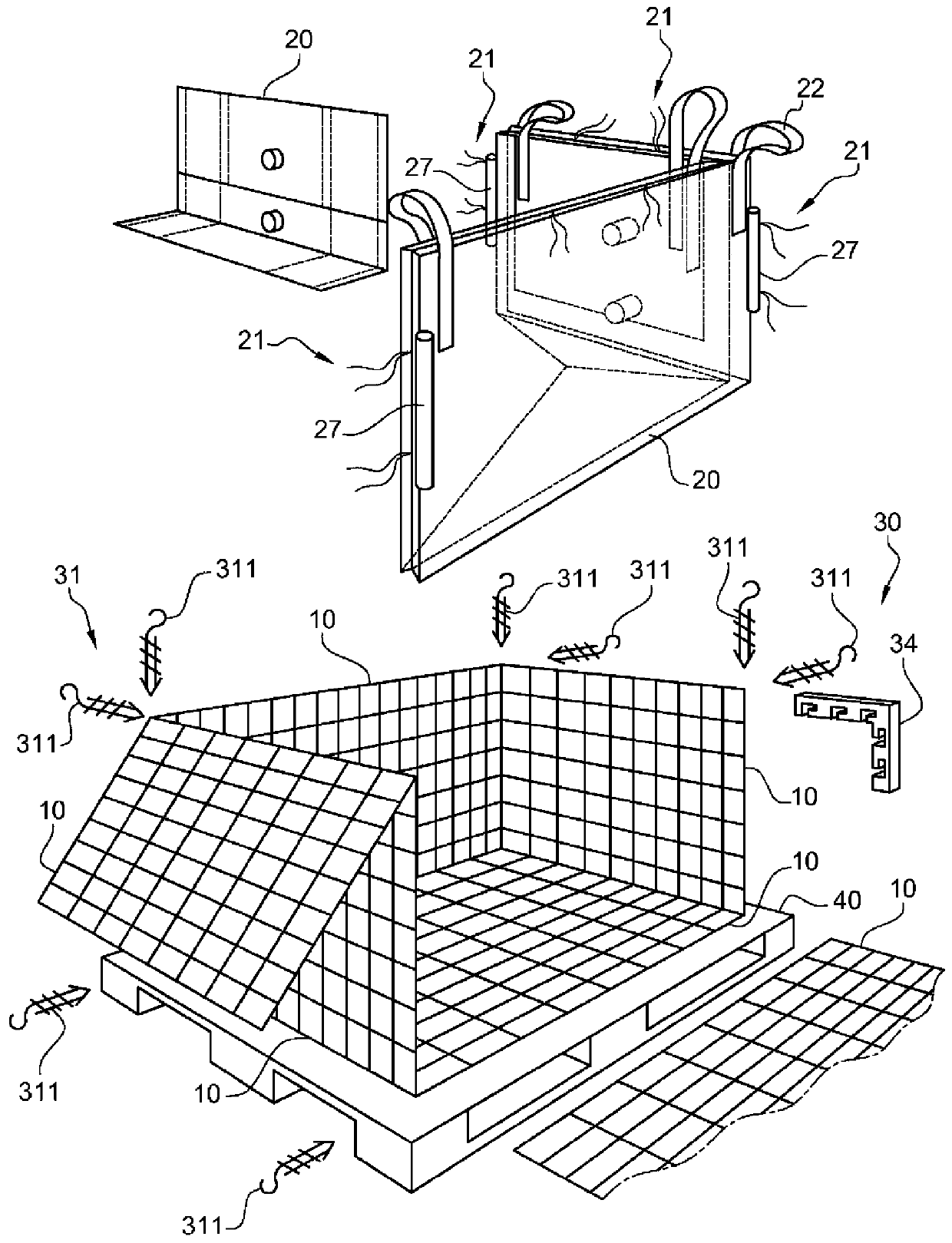

[0059] Figures 1 to 13 A foldable modular package (1) and its constituent elements according to a preferred embodiment of the invention are shown.

[0060]The package (1) comprises six panels (10), a flexible inner container (20) and an assembly system (30).

[0061] Six plates (10) are movable between the following positions:

[0062] - a folded position in which the panels (10) are stacked on top of each other, and

[0063] - A deployed position, in which the panels (10) form a parallelepiped frame (11), which is cuboid in shape, defining a hollow internal volume (12).

[0064] Each plate (10) presents a grid made of wire. The position of the frame lines can be different, intersecting or alternating. The plates ( 10 ) can be assembled by welding with the two wires in contact according to a screen defined by their chains and frames suitable for the application of forces. The plate (10) is treated against corrosion and free from any roughness.

[0065] Preferably, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com